- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- impact bar

Results for

Impact bar - Import export

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The impact elements consist of three components which are connected to each other by hot vulcanisation a special rubber mix with a shore hardness of 62° A which absorbs the occurring drop energy a coating of highly sliding UHMWPE and a thickness of 12 mm a vulcanised aluminium profile for easy installation of the bars

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanShock® IP B - Fasteners Available dimensions: Type: T35 Size: M12 / M16 Length: 40 / 60 / 90 mm Note: Please order germanShock IP B fasteners separately.

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

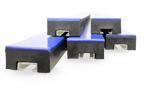

germanShock® IP 60 Available dimensions: Height: 50 / 75 / 100 mm Width: 100 mm Length: 1,220 / 1,500 mm Specifications: Colour (UHMWPE): blue Hardness: 60 ° Shore A Mounting: Vulcanised aluminium fastening profile Downloads: Technical Data Sheet germanShock® IP 60 - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanShock® IP 45 Available dimensions: Height: 50 / 75 / 100 mm Width: 100 mm Length: 1,220 / 1,500 mm Specifications: Colour (UHMWPE): red Hardness: 45 ° Shore A Mounting: Vulcanised aluminium fastening profile Downloads: Technical Data Sheet germanShock® IP 45 - English [PDF]

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanShock® IP 45 Available dimensions: Height: 50 / 75 / 100 mm Width: 100 mm Length: 1,220 / 1,500 mm Specifications: Colour (UHMWPE): red Hardness: 45 ° Shore A Mounting: Vulcanised aluminium fastening profile Downloads: Technical Data Sheet germanShock® IP 45 - English [PDF]

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Horizontal Shaft Impactor (HSI) commonly referred to as a Tertiary Impact Crusher is a type of crushing equipment used to further reduce materials that have been processed through primary and secondary crushers into even finer particles. The last stage of crushed materials with exact particle sizes and shapes are usually produced by tertiary impact crushers. They work by applying high-speed impacts to break down the material using a horizontal shaft fitted with hammers or blow bars. A tertiary impact crushers main purpose is to refine the product to the appropriate size and shape in order to meet particular needs in a variety of applications including mining recycling and aggregate production. By producing finely crushed products appropriate for end-use applications tertiary impact crushers play a critical role in the last stage of material processing.

Request for a quote

PRO DESIGN

Turkey

Bottle glorifiers are custom-designed display units that elevate and showcase premium or specialty bottles of liquor, wine, or other beverages in retail or hospitality settings. These displays typically feature illuminated platforms, custom branding elements, and strategic lighting to draw attention to featured bottles and create a captivating visual impact. Whether used on bar counters, liquor store shelves, or restaurant backbars, bottle glorifiers enhance the presentation of high-end products, reinforce brand identity, and stimulate customer interest and purchase intent. With customizable designs and branding options, bottle glorifiers offer retailers and brands an effective way to differentiate their offerings and drive sales.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Tertiary Impact Crusher can be understood as a kind of crushing machine to carry out further reduction of material past primary and secondary crushers. The Tertiary Impact Crusher works as an HSI. The stocky rotor customer-engineered by General Kinematics to have impact tools blowing bars or hammers turning at higher speeds smashes the material. These impact tools work extremely fast to achieve impacts that will break down the material into small, homogenized, and delicate particles. Our Tertiary Impact Crushers are designed for making optimal shaped aggregates and crushed materials with high fineness, for maximum control over particle size and shape and contributing to the achievement of product requirements in various industries and applications. Tertiary Impact Crushers are important in the final stage of crushing. This has been declared to be the final shattering that the materials undergo, which puts them to the characteristics needed in the end product.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The Horizontal Shaft Impactor (HSI) commonly referred to as a Tertiary Impact Crusher is a type of crushing equipment used to further reduce materials that have been processed through primary and secondary crushers into even finer particles. The last stage of crushed materials with exact particle sizes and shapes are usually produced by tertiary impact crushers. They work by applying high-speed impacts to break down the material using a horizontal shaft fitted with hammers or blow bars. A tertiary impact crushers main purpose is to refine the product to the appropriate size and shape in order to meet particular needs in a variety of applications including mining recycling and aggregate production. By producing finely crushed products appropriate for end-use applications tertiary impact crushers play a critical role in the last stage of material processing.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The impact elements consist of three components that are connected to one another by hot vulcanization A special rubber compound with a hardness of 62 ° Shore A, which absorbs the falling energy A top layer made of high sliding UHMWPE and a thickness of 10 mm A vulcanized aluminum profile for easy installation of the beams Special bolts with M16x40 also available in M12

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

high level of dust sealing at the location where material is fed onto the belt conveyor minimal wastage a buffer for the material falling onto the belt conveyor reduced cleaning costs increased conveyor belt service life increased operational safety simple assembly no welding necessary exchange of the adapter piece for existing conveyor rollers Measurements of the impact bars approx. 1240 x 100 x 75 (L x W x H) The impact bars can be fitted using the enclosed screws optimal alignment of the skirting rubber on the conveyor belt

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanShock® impact bars germanShock® IP impact bars replace conventional buffer rollers at in-feed and absorb the impact energy of dropping bulk material, thus reducing damage to the belt. Combination with our germanLine® skirting rubber provides effective side sealing at in-feed. ... more

Request for a quoteResults for

Impact bar - Import exportNumber of results

15 ProductsCountries