- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic shearing machine

Results for

Hydraulic shearing machine - Import export

METAL IN LTD

Bulgaria

The modern equipment with CNC machines, which we possess allow us to work sheet iron with thickness till 18 mm and dimensions 1500x3000 mm. These products are with high quality, precise manufacturing and excellent external look. Thank to different machines and equipment (lazer cutting, stamp press, punching, shears, eccentric and hydraulic presses, machine shafts, bending machine for metal sheets straightening , spot welding, robotic MIG-MAG welding, WIG welding, powder coating. The company produce big variety of products as the more important are: Hydraulic reservoirs Metal boxes for electronics Wardrobes Cabinets for instruments Metal cabinets for coffee machines Front panels for professional speakers Fireplaces, burners and barbecues Gun safes and storage of documents Control panels for machines Doors and lids for machines and vacuum cleaners Equipment for stores Lamps for lighting Steps of excavators

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

Rigidly welded all-steel frame construction Design with "variable-rake" concept Adjustment of machine functions with easy to use CNC control unit Compact, low-maintenance European hydraulics Hydraulic overload protection All of the components and materials on the machine are world wide known brand names. We produce the machine from 3080mmX6mm until 8100mmX10mm

GSW SCHWABE AG

Germany

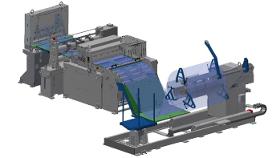

GSW Shears find their place in CutToLength Lines or as Scrap Choppers. They are used to perform lasting and costefficient, no matter the roughness of the environment. Our pneumatic and hydraulic Shears are designed efficient in any way – and from 60 to 1500mm width The pneumatic machines run with up to 500 SPM while their heavy types are robust enough to lastingly process up to 3mm thick materials. Since they do not need hydraulic power or electric controls, they are extremely costefficient. If a combination of high SPM and thicker materials is necessary, our TSHL „light“ hydraulic Shears offer the solution. The TSHS series machines are built very heavy and stiff which allows them to cut up to 12mm thick materials. If yet larger widths than 1500mm are to be processed, we work together with most reliable German partners who supply us with highquality Shears in hydraulic, electric or servoelectric design. This way we can offer the very best suitable solution for any application.

Request for a quote

GSW SCHWABE AG

Germany

Also Slitting Lines do of course belong to the family of Cutting Lines. They are suitable especially for such customers who have to control a large portfolio of coil widths within their production. And if you build quality products you need quality even in your primary material. Finding it requires a good Steel Service Center but can be costly and unavailable at time of need. So why not cut your own coils? Our Slitting Lines are optimized for smaller batches and provide flexibility supporting your deadlines.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GSW SCHWABE AG

Germany

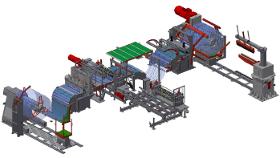

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

SCHNELL SPA

Italy

Rebar shearing machine for fast bars cutting. Cutting antirepetitiveness system. Capacity 1 bar Ø 32 mm 90 cuts/minute

Request for a quote

WRIGHTS RECYCLING MACHINERY LTD

United Kingdom

The KN hydraulic demolition shears have a 360 degrees rotation, making effective work for demolition, scrap metal, general waste, ferrous and non-ferrous companies. Reducing waste in the quickest and most cost effective way. The KN demolition shears are one of the best quality built shears on the market today with faultless welding and high quality materials used building the shears, it takes a lot of operator malfunction to damage to shears.

Request for a quote

MVD MACHINERY

Turkey

Unique components that reduces maintenance need. Made to run for many years at toughest conditions for great cuts. Unique construction features combined with great craftmanship Machine body and upper beam’s steel constructions have been designed according to minimum stretch and optimum resistance criteria.

Request for a quote

HTMACH - HT GRUP MAKINA A.S.

Turkey

Cast iron table and foot bases Large table facilitating the command of sheet metal by operator Cutting lever made of low carbon steel for the purposes of flexibility and stability Mechanical pressure system which prevents sliding of sheet metal during cutting operation Mono-block lower knife made of air hardened steel (spk-2080) Front set-square appropriate for angle sheet metal cutting and millimeter set-square appropriate for vertical cutting

HTMACH - HT GRUP MAKINA A.S.

Turkey

Welded all-steel frame providing maximum rigidity and cutting accuracy Economic and strong design Easy to use control unit All of the components on the machine are world wide known brand names.

LVD

Belgium

Custom-designed MVS Series hydraulic shears are configured to meet your needs. Based on the robust MVS platform, each custom shearing machine is ruggedly constructed to minimize deflection for the best shearing accuracy. A touch screen control simplifies operation – users can learn the machine in just 10 minutes. Configurable specifications optimize rake angle, blade clearance, backgauge range and more. KEY FEATURES Intuitive touch screen control Touch-and-Go recirculating backgauge system features automatic backlash elimination Push-button adjustable stroke length, blade gap and rake angle optimize cutting Ball transfer system simplifies material processing Large throat gap permits overlap cutting PERFORMANCE-ENHANCING OPTIONS Pre-order, configurable material handling options MODELS From 20 mm x 6200 mm up to 40 mm x 14000 mm Specifications Hydraulic shearing system with up to four cutting edges

Request for a quote

LVD

Belgium

The HGS guillotine shearing machine makes heavy-duty shearing affordable. Frame and cutting beam offer maximum rigidity and resistance to deflection and torsional force for accurate shearing of mild steel up to 30 mm. This guillotine shear features four cutting edges that can be turned three times before grinding for increased production life. Cost-efficiently manufactured, HGS shears fit your needs and your budget. KEY FEATURES Intuitive touch screen control Adjustable rake angle for optimum cutting control Rake angle adjustment at 0.5 degrees minimizes distortion when shearing narrow strips, reduces or eliminates corkscrew and bow distortions Automatic calculation of blade clearance and cutting angle based on material and thickness PERFORMANCE-ENHANCING OPTIONS Squaring / front arms MODELS From 10 mm to 30 mm cutting capacity Specifications Maximum shearing capacity: mild steel 45 kg/mm from 10 mm to 30 mm, depending on model

Request for a quote

LVD

Belgium

MVS Series hydraulic shears are built to be productive. Able to cut a range of material types and tensile strengths, their flexibility suits virtually all shearing needs. A heavy-duty frame minimizes deflection for accurate cut quality and long production life. The ease of touch screen programming makes start-up and operation fast and simple – train an operator in just 10 minutes. KEY FEATURES Intuitive touch screen control Touch-and-Go backgauge system Push-button adjustable stroke length, blade gap and rake angle optimize cutting Ball transfer system simplifies material processing Large throat gap permits overlap cutting PERFORMANCE-ENHANCING OPTIONS Swing-away backgauge for cutting larger workpieces Sheet support system(offered on certain models) Front sheet supports MODELS Up to 13 mm by 6200 mm Specifications Hydraulic shearing system with up to four cutting edges Maximum shearing capacity:mild steel 45 kg/mm from 6,35 mm to 13 mm, depending on model;stainless steel

Request for a quote

LVD

Belgium

The CS Series guillotine shearing machine tackles a range of general shearing applications. Offering exceptional value for the investment, each CS guillotine shear is built to a high-quality standard using components that meet stringent accuracy and reliability requirements. With a CS shearing machine, you’re assured of consistent-quality cutting results in a cost-efficient design. KEY FEATURES Easy-to-use motorized 1000 mm range backgauge Shadow Line cutting capability 1,5 m squaring arm Front support(standard on CS 13/31) MODELS CS 6/31 (6,35 mm by 3,1 meter) CS 6/40 (6,35 mm by 4,05 meter) CS 13/31 (13 mm by 3,1 meter) Specifications Parallel-guided shearing using four cutting edges Maximum shearing capacity:mild steel 45 kg/mm from 6,35 mm to 13 mm, depending on model;stainless steel 60 kg/mm from 4 mm to 8 mm, depending on model Cutting length:3100 mm or 4000 mm, depending on model

Request for a quoteResults for

Hydraulic shearing machine - Import exportNumber of results

16 ProductsCompany type