- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic hammers

Results for

Hydraulic hammers - Import export

TECHNOPARK IMPULSE LLC

Russia

Impulse Classic hydraulic breaker is an updated model line. The main difference from the same class breakers is reduced required pressing force of the working tool to start operation. While keeping an affordable price, Impulse Classic piston breakers have approached to the characteristics of diaphragm class, providing a significant increase in productivity - up to 25-30%. The main advantages of the new line are reliability, maintainability and availability. •Unique design: absence of tie through-bolts of the impact block eliminates the scoring on piston and cylinder •Change of wearing parts is done quickly. No press or puller required •Protection against idle strikes •Easy maintenance •Guaranteed to be protected against corrosion before the first start-up of the breaker •Upgraded technology of catalytic nitriding, which extends the life of the piston pair by 2.5 times •Reduced weight, which allowing to install a more powerful hydraulic breaker on the base machine.

Request for a quote

TECHNOPARK IMPULSE LLC

Russia

Impulse Classic hydraulic breaker is an updated model line. The main difference from the same class breakers is reduced required pressing force of the working tool to start operation. While keeping an affordable price, Impulse Classic piston breakers have approached to the characteristics of diaphragm class, providing a significant increase in productivity - up to 25-30%. The main advantages of the new line are reliability, maintainability and availability. •Unique design: absence of tie through-bolts of the impact block eliminates the scoring on piston and cylinder •Change of wearing parts is done quickly. No press or puller required •Protection against idle strikes •Easy maintenance •Guaranteed to be protected against corrosion before the first start-up of the breaker •Upgraded technology of catalytic nitriding, which extends the life of the piston pair by 2.5 times •Reduced weight, which allowing to install a more powerful hydraulic breaker on the base machine.

Request for a quote

KW HYDRAULIK GMBH

Germany

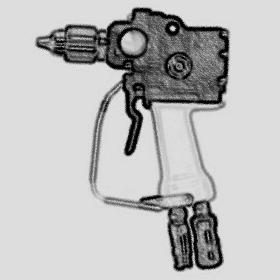

Hydraulic Hammer Drills

Request for a quote

KW HYDRAULIK GMBH

Germany

Hydraulic Drilling Machines Hydraulic Core Drills Hydraulic Earth Augers Hydraulic Mounted Earth Augers Hydraulic Ground Drivers Hydraulic Post Drivers Brochure Drilling Machines Screw Drivers Hammer Drills Impact Wrenchs Hydraulic Hammer Drills Hydraulic Sinker Drills Hydraulic Impact Wrenches Hydraulic Angle Drilling Machine Valve Opener Hydraulic Post Puller Hydraulic Self Driving Drilling and Pile-Driving Machines

Request for a quote

FERRUM-MASCHINEN EIN BEREICH DER KMS AUTO UG (HAFTUNGSBESCHRÄNKT)

Germany

hydraulic demolition hammer for Ferrum DM yard loader / wheel loader suitable for all models listed below requires 3rd control circuit with connection for quick coupler Ideal for breaking up masonry, concrete slabs and asphalt => We can also do any other for a small additional charge Deliver the recording appropriately . All we need are the exact dimensions and a drawing. Please contact us if necessary. Recommended for: Wheel loader Ferrum DM308 x4 V2 Ferrum DM312 x4 Ferrum DM416 x4 V2 Ferrum DM522 x4 Ferrum DM430 x4 DLZ Ferrum DM625 x4 Ferrum DM732 x4 Court loader: Courtyard loader FIRST 12 Courtyard loader FIRST 16

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VESTA PETROKIMYA URUN. VE ENERJI SAN. TIC. LTD. STI.

Turkey

Lithium Complex Moly is an extreme pressure lithium grease specially crafted with a lithium complex thickener. This advanced grease excels under extreme conditions, credit to its extreme pressure additives and a 3% molybdenum disulphide content. Additionally, it incorporates specific additives designed to shield equipment from oxidation, high temperatures, and corrosion. This grease exhibits remarkable resistance to water and boasts exceptional adhesion, rendering it the ideal choice for applications in wet environments and under the most demanding working conditions. Highly recommended for lubricating heavy-duty mechanisms enduring extreme loads and extended greasing intervals, particularly in the mining and construction sectors. Well-suited for lubricating sleeve bearings, hydraulic hammer bearings, open gears, fifth wheels, and front-end loader bolts. Suitable for use in a temperature range spanning from -10°C to 150°C.

Request for a quote

PROJECT DRILL

Italy

N ° 1 Comacchio brand drilling rig, model GEO 205 Year 2008 CE certified Rubber tracks Kubota diesel engine, 47 hp Useful stroke 2800 mm Max pull: 2500 kgm Rotation head with max torque 200 kgm and max speed up to 500 rpm double vice with max passage 220 mm Winch Hydraulic hammer installed on the rotation head Extension for winch Very good general conditions Immediately available Viewable at our office

Request for a quote

PROJECT DRILL

Italy

N ° 1 TEC brand drilling rig, GALAXY model. Year of construction 2009. Engine running hours: 1600 Deutz brand diesel engine, power 100 hp Stroke for rods of length 3000 mm Max pull 7000 kg Mast rotation of + - 20 ° to the right / left Rotation head with max torque 650 kgm; variable displacement piston engine. Maximum speed 600 rpm Double vice with maximum passage 250 mm Winch with maximum pull 1500 kg @ 1st layer Triplex borehole pump: max flow rate 140 lt / 1 ', pressure 50 bar Track control with remote control panel Positioning command on the machine Drilling controls on articulated arm Metal tracks with rubber pads General conditions: excellent Immediately available Possible options: Wire line winch Automatic SPT Hydraulic hammer kit - drifter

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Find Air Leaks. Decrease Energy Consumption. Maximize Uptime. Compressed air is the most versatile and therefore widely used resource in industry. Using atmospheric pressure to transfer energy during industrial processes, compressed air can be found powering air tools like drills and hammers, hydraulic air cylinders for automation in manufacturing processes and much more. Compressed air is also used to power air brakes on mobile fleets and trains. Air Compressor Expenses It is so commonly found in industry it is often referred to as the fourth utility to electricity, water and gas. Of the four, compressed air consumes the most energy. Air compressor systems can differ very greatly in size, output and cost. What remains constant, is the initial investment in a compressor system is only 25% of the expenses associated with it, over its lifetime. The other 75% of the costs go to energy used to compress the air.

Request for a quote-20Bild0358f5d1f62a4718.82_4d26c671.jpg)

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Correctly processed residual wood and waste wood constitute a valuable raw material. The Impact Hammer Mill, series PHPS converts pre-shredded residual wood and waste wood of any kind into valuable raw material for material and thermal recovery. Even contaminated materials can be processed. Heavy foreign objects in the feed material are separated and automatically discharged. Characteristics, Function Material feeding is vertically from above Heavy, rotating hammers break the material and throw it against the impact plates The wood is split along the grain and enclosed metal contaminants are set free, separated and discharged Further processing of the wood pieces is effected by stationary breaker and comb bars The end fineness is determined by the perforation of the integrated screen Split housing design allows hydraulic opening Sturdy disc rotor is stress-relieved Adjustable separation degree of the discharge chute for metal pieces Device for hydraulic hammer...

Request for a quote-20Bild0358f5d1f62a4718.82_4d26c671.jpg)

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Correctly processed residual wood and waste wood constitute a valuable raw material. The Impact Hammer Mill, series PHPS converts pre-shredded residual wood and waste wood of any kind into valuable raw material for material and thermal recovery. Even contaminated materials can be processed. Heavy foreign objects in the feed material are separated and automatically discharged. Characteristics, Function Material feeding is vertically from above Heavy, rotating hammers break the material and throw it against the impact plates The wood is split along the grain and enclosed metal contaminants are set free, separated and discharged Further processing of the wood pieces is effected by stationary breaker and comb bars The end fineness is determined by the perforation of the integrated screen Split housing design allows hydraulic opening Sturdy disc rotor is stress-relieved Adjustable separation degree of the discharge chute for metal pieces Device for hydraulic hammer...

Request for a quoteResults for

Hydraulic hammers - Import exportNumber of results

12 ProductsCountries

Company type