- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hot and cold rolling

Results for

Hot and cold rolling - Import export

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

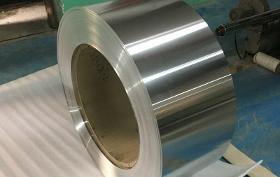

Standard: AISI, ASTM, GB Place of Origin: China Technique: Cold Rolled/hot rolled Surface Treatment: Polished Application: Construction, Construction and hardware Thickness: 0.25mm-25mm Width: 16-1500mm Length: Customers' Requirement Certificate: ISO9001/SGS/BV Type: Steel coil Edge: Round Surface: Black Supply Ability: 5000 Ton/Tons per Month Hardened and tempered heat treatment steel strip for construction Packaging Details: standard sea worthy package Payment Term: T/T,L/C etc. Port of shipment: Xiamen,China

Request for a quote

DOGA MAKINA

Turkey

Cold and hot drawing rolling mills, ring, roller, roller, disk or forming roller ring etc., called profile, wire, cable, electrode, iron, copper etc. The processing, manufacturing or, if desired, the correction of the rolling mills used in the drawing of materials such as profile, wire, cable, electrode, iron, copper etc. By performing highly precise cnc machining, both the quality of the product to be obtained is increased and the optimum benefit is provided to the customer by extending the life of the rolling mills used. By correcting the rolling mill tool, the customer's remanufacturing costs are reduced and the service life of the rolling mill tools is increased. Now these roller rings are processed and manufactured in the same quality in Turkey.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Product name: hot/cold rolled steel sheet coil Standard: AISI, ASTM, BS, DIN, GB, JIS Grade: SPCC,DC01,DC03 Place of Origin: China Technique: Hot rolled,cold rolled Surface Treatment: Coated,Galvanized,Embossed Application: Construction, building, electric industry, etc. Special Use: High-strength Steel Plate Width: 600mm-1250mm Length: Customer's Requirement Coil weight: as per customers' requests Certificate: ISO Color: sliver Package Type: Exporting standard packing Lead time: 15-30days Payment term:T/T,L/C etc. Port of shippment: Xiamen

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

To produce industrial aluminum of this caliber, Novelis begins by carefully controlling the composition of the alloy, then taking exceptional care in the casting procedure to avoid non-metallic impurities. The surfaces of the aluminum ingots are then sawed and scalped to remove any new impurities before rolling. These ingots are preheated for long periods for optimal homogenization of the metal structure, then hot- and cold-rolling procedures achieve high surface quality. “Bright rolling” delivers the highest possible surface consistency and reflectivity. The result is an aluminum surface reflective enough to be used as a mirror.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis is the global leader in rolled aluminum products and aluminum beverage can recycling. Our technical competence and innovation have made us a development partner chosen by leading companies from the automotive, building, printing and packaging industries, among others. With its customer orientation and strong industrial performance, Novelis plays a crucial part in shaping products for the future. The aluminium content means that there is only slight thermal length variation, just like with metal tubes. In addition, the tubes become completely oxygen-impermeable, which is indispensable when connecting radiators, for example. Using state-of-art production facilities and experienced specialists, Novelis ensures top quality in the manufacture of its products – across the entire production process, from casting and processing the ingots via hot and cold rolling, to packaging.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We supply from the productions and our stocks ; the galvanized flat steel that is hot-dipping of cold- rolled metal through a zinc bath where both surfaces are coated with layer of zinc applied in order to enhance material lifespan and prevent corrosion which will eventually occur on the material surfaces in the presence of water or air moisture. Hot Dip Galvanized Steel Coils and / or Sheets Cut From Coils, Zero Spangle, Chromated, Unoiled Acc. to EN 10346/EN 10143 Drawing Steel Grades; DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z Structural Steel Grades; S220 GD+Z, S250 GD+Z, S280 GD+Z, S320 GD+Z, S350 GD+Z.. Coating Thickness from 50 gr/m2 to 300 gr/m2 Thickness from 0,2 to 4 mm. “Please contact with our Sales Department for the current Stock Delivery Options for DX51D+Z275 Sheets/Coils”

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

Applications Pipes for the construction of pipelines for water, liquid hydrocarbons, natural gas and for the construstion of chemical and industrial plants, refineries etc. Norms Line pipes are according to the following norms: API 5L (ISO3183) (seamless and welded pipes) ASTM A53 / ASME SA53 (seamless and welded pipes) Manufacturing methods Seamless pipes, hot rolled or cold finished with following heat treatment: ERW pipes up to dia 24" and SAW pipes for the other sizes.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We can supply pipes for the construction of pipelines, equipment and tanks subject to low temperatures as Seamless or welded pipes, hot rolled or cold finished. Pipe norms suitable for low temperatures are according to; ASTM A 333 / ASME SA 333 (seamless and welded pipes) EN 10216-4 (Seamless pipes) EN 10217-4 (Welded pipes)

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We supply the pipes that are suitable for bending and are used for the constructions of plants and equipment subject to high temperatures and pressures. The seamless pipes, hot rolled or cold drawn/cold finished with heat treatment. The ASTM A335/ASME SA335 and EN 10216-2 norms require heat treatment also for the hot rolled pipes. The welded pipes are manufactured according to EN 10217-2. Supply of pipes suitable for high temperatures are according to; ASTM A 106 / ASME SA 106 (Seamless pipes) ASTM A 335 / ASME SA 335 (Seamless pipes) EN 10216-2 (Seamless pipes) EN 10217-2 (Welded pipes)

Request for a quote

ILK IHRACAT AS.

Turkey

Galvanized Coated Steel Sheets are products obtained by subjecting hot or cold rolled sheets to zinc coating process, the surface of which is brightened and strengthened against corrosion. It is offered in various grades such as DX51, DX52, DX53, DX54, DX56, S220GD, S280GD, S320GD, S350GD, HX260LAD, HX300LAD, HX340LAD. Application Areas and Advantages: Wide usage in sectors such as automotive, white goods, machinery manufacturing, construction sector, industrial warehouse solutions, cooling heating systems, transportation systems. Zinc coating increases corrosion resistance and makes the product more durable. The amount of coating varies according to demand and place of use. Galvanized Coated Steel Sheet, which is coated with zinc by dipping or electrolytic coating method to increase the corrosion resistance of the steel sheet, is usually coated with a total of 100-300 gr / square meter on both surfaces.

Request for a quote

DEL' LA SOFT

Turkey

this is Rolled Wıpes also known as OSHI BORI it is a product above standart single use wet wipes with the quality of towels and essences. You can serve hot by heating in a special oven and cold in a refrigerator in summer. Your brand will gain prestige with this unique product that carries your logo. For COLD using, you can put the item in your refrigerator about 30 min. between 0-8 degrees then it can be cold service. For HOT using, you can put the item inside of towel heater about 30-40 min. then it can be hot service. for more feel free to contact us

Request for a quote

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

- Wide range of steel grades: structural, cold forming, HSLA, etc. - In coils or cut-to-length - Standard os curtomized sizes

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Copper Strips are manufactured from highly conductive and thin thickness. They are windly used in automotive industry; radiators, cable industry, electronic and electrical industries; decorative components and Building industry: roofings.etc. Coper Strips are ideally used in applications where the salt content in the soil is very high, with a width of 5mm to 160mm, Thickness of 0,10mm to 10mm. Copper strips are produced, hot and cold rolling , by extruded OF busbars and they are accordıng with TS EN 1652, DIN EN 1652, DIN EN 13599 also EN 13601

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Copper Strips are manufactured from highly conductive and thin thickness. they offer great resistance to corrosion.They are widly used in automotive industry; radiators, cable industry, electronic and electrical inustries; decorative components and Building inustry: roofings.etc. Coper Strips are ideally used in applications where the salt content in the soil is very high, with a width of 10mm to 160mm, Thickness of 0,20mm to 6mm. Copper strips are produced, hot and cold rolling , by extruded busbars and they are accordıng with TS EN 1652, DIN EN 1652, DIN EN 13599

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GURPAK DISPOSABLE PACKAGING AND FOOD LIMITED

Turkey

Hot-Cold Luxury Rolled Towels with higher standards Premium interior textile with gentle texture CMYK or flexo printing techniques up to 8 colors Non-alcohol fragrance options Packaging alternatives suitable for your distribution channel

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

COLORICIO.SRL

Romania

Coloured rolled steel is a flat steel product that is coated in decorative protective paint . The polymeric coating may be : glossy , mate or mimicking a natural decorative finish ( wood, granite,...etc ) The paint may be applied both on hot rollrd elements and cold rolled elements with no metal coating.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc.

Request for a quoteResults for

Hot and cold rolling - Import exportNumber of results

48 ProductsCountries

Category

- Cold rolled steel strips (7)

- Foundries - copper, bronze and brass (6)

- Copper and copper alloys (4)

- Rolling mills - machinery and installations (4)

- Steel, carbon (4)

- Copper sheets and bands (2)

- Galvanization - steels and metals (2)

- Steel & Metals (2)

- Aluminium alloys (1)

- Aluminium and aluminium alloys (1)

- Brazing - equipment and supplies (1)

- Casting of special and high-grade steels (1)

- Cleaning and maintenance products, industrial (1)

- Cold rolled sections (1)

- Metal structural work (1)

- Metallization (1)

- Napkins, paper (1)

- Pipes and tubes, aluminium (1)

- Pipes and tubes, steel (1)

- Piston rings (1)