- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- horizontal mixers

Results for

Horizontal mixers - Import export

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

Lödige laboratory mixers of type L5, L10, L20 or L50 have a total drum volume of 5, 10, 20 or 50 litres. The ploughshare shovels in special arrangement on a mixing shaft in a horizontal, cylindrical drum rotate closely to the wall. Their peripheral speed and geometric form are coordinated in such a way that the mix is moved out of the product bed against the centrifugal force and in axial direction at the same time. All the product is constantly involved in the process, ensures a maximum mixing intensity at even the highest throughputs and shortest residence times until the product is discharged out of the mixer via an outlet. Thanks to their form adapted to individual application and the speed adjustment, Lödige ploughshare mixers can be used for a wide range of applications – for processing bulk solids (powdery, grainy, fibrous) or pumpable products. Choppers can be additionally installed in the mixing drum to increase the turbulence in the mixing process.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used for homogeneous mixing of powdered and granular products

Request for a quote

UMMANMAK

Turkey

UMMAN Twin Shaft mixers, which are offered in a wide capacity range from 1 m³ concrete to 4 m³ concrete production, optionally such as 2 or more discharge caps, special design for RCC production, high pressure mixer interior washing, humidity and temperature sensor, etc. according to the project and application requirements. equipment can be installed. It offers comprehensive and wide-ranging high-performance solutions suitable for all concrete needs of its customers. Our Umix Ts twinshaft Mixers have two horizontally mounted mixer shafts and are the ideal mixer type in terms of concrete mixing time and quality. It is preferred by companies that want medium and high capacity.

Request for a quote

KASAG SWISS AG

Switzerland

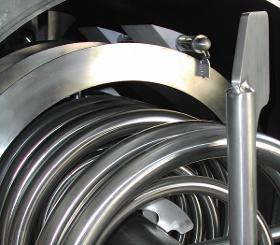

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

JING HENG SING TECHNOLOGY CO., LTD.

Taiwan R.O.C.

Ribbon mixer is most suitable for uniformly mixing granular and powdery materials. The spiral twin screw design inside the mixer increases the mixing speed as well as the uniformity of the resulting mixture. The advantages of the ribbon mixer are its economical price and easy maintenance. High consistency uniformity can be achieved in approximately 7-15 minutes per mixing batch. Suitable materials, such as sugar, cream, instant coffee powder or frying powder, etc. can also be fed into the machine via nozzles or via liquid pumps for liquid mixing. Options for combined equipment are pumping systems, weighbridge or powder feeding stations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALCHEMIST TECHNOLOGIES

Turkey

It is connected to the tractor by the towing system. • Takes the movement from the tractor tail shaft. • Hydraulic systems in the feed mixer machine provide a comfortable use by the ergonomic control arms extending up to the user. • Feed mixer is produced in order to ensure a homogeneous mixture of different feeds and to distribute this mixture equally to animals. Thanks to this machine, feed utilization coefficients of animals are maximized. • Feed feed prepared with feed mixer is easier to digest. NOTE: Optionally; Equipment such as the double-sided discharge cap and digital scale, hydraulic grab can be added to the standard package. • A significant increase in the meat and milk yield of animals is achieved. • Feed (ration) prepared with feed mixer is more homogenous than the feeds which are fed by hand, this homogeneity allows the animals to eat more feed.

Request for a quote

ALCHEMIST TECHNOLOGIES

Turkey

It is connected to the tractor by the towing system. • Takes the movement from the tractor tail shaft. • Hydraulic systems in the feed mixer machine provide a comfortable use by the ergonomic control arms extending up to the user. • Feed mixer is produced in order to ensure a homogeneous mixture of different feeds and to distribute this mixture equally to animals. Thanks to this machine, feed utilization coefficients of animals are maximized. • Feed feed prepared with feed mixer is easier to digest. • A significant increase in the meat and milk yield of animals is achieved. • Feed (ration) prepared with feed mixer is more homogenous than the feeds which are fed by hand, this homogeneity allows the animals to eat more feed. • Meat consuming feed mix machine will consume feed at the same rate and with the same homogeneity.

Request for a quote

ALCHEMIST TECHNOLOGIES

Turkey

•The machine works with an electric motor. • Feed mixer is produced in order to ensure a homogeneous mixture of different feeds and to distribute this mixture equally to animals. Thanks to this machine, feed utilization coefficients of animals are maximized. • Feed feed prepared with feed mixer is easier to digest. • A significant increase in the meat and milk yield of animals is achieved. • Feed (ration) prepared with feed mixer is more homogenous than the feeds which are fed by hand, this homogeneity allows the animals to eat more feed. • Meat consuming feed mix machine will consume feed at the same rate and with the same homogeneity. • Feed mixer fills fiber feed by chopper blades. It provides homogeneity by mixing the fiber feeds which are shredded with the other feed materials. In this way; fiber feeds are prevented from being digested without digestion.

Request for a quote

MIXACO MASCHINENBAU

Germany

Gentle Mixing Without Tools MIXACO Revolution™ is mixing system that functions without tools. Gentle mixing of materials during rotation of the container is achieved with built-in mixing segments. This technology without driven mixing tools prevents additional thermal stress for the product. All Benefits at a Glance •Gentle homogenization •No inadvertent warming of mixing materials •No abrasion of granulates •Double-walled mixing vessel allows temperature-controlled mixing •Energy-efficient through low drive power consumption •100% discharge by pivoting to discharging position •Good accessibility for fast, easy cleaning •Tool-free design makes maintenance easy •Suitable for ATEX applications (up to Zone 20 without inertization of protective gases)

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Heating/Cooling Mixer MIXACO’s combined heating/cooling mixers are the optimum solution for complex mixing challenges. The systems are characterized by their outstanding product preparation in the heating phase and high-efficiency cooling performance. The horizontal and vertical heating/cooling mixers are designed for high-volume throughput, rapid processing and short cleaning times. The Relaunch of a Classic Tried and Tested Technology With New Product Concept and Attractive Price-Performance Ratio The consistent development of tried and tested technology is a MIXACO hallmark, which also applies to our heating/cooling mixers. The product line has been completely redesigned following comprehensive analyses of all components. In addition, our range of international maintenance and support services are optimized continually and are under continuous review.

Request for a quoteResults for

Horizontal mixers - Import exportNumber of results

11 ProductsCompany type