- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high-performance machining

Results for

High-performance machining - Import export

MÜLLER HYDRAULIK GMBH

Germany

FOR HIGH-PERFORMANCE MACHINING UP TO 27 L/MIN Pure power! Filter finenesses of up to 25 μm and an integrated bypass filtration of the machine tank is no problem thanks to the optional automatic filter. The control pump generates up to 15 °C less heat compared to conventional pumps, and using pressure of up to 300 bar, even smallest bores can be realised.

Request for a quote

SC PROFINOX SRL

Romania

We provide stainless steel sandblasting and grinding services to obtain smooth and clean metal surfaces. The stainless steel sandblasting procedure is environmentally friendly and highly efficient. For finishing metal surfaces, Profinox provides glass sandblasting services – a procedure that does not contaminate surfaces with iron. This consists in propelling glass granules in the form of a jet at very high speeds directly onto the surface of metal parts. As one of the most important aspects reflecting the quality of a product is the finish of the product itself, our stainless steel sandblasting service enables us to perform high-quality surface machining, as sandblasting with glass granules makes it possible to treat even the most difficult to penetrate areas and gives a clean and smooth look to the product. Another important function of stainless steel sandblasting is to significantly improve the final appearance

Request for a quote

SC PROFINOX SRL

Romania

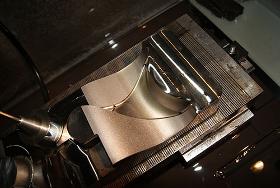

We offer sheet metal rolling services performed according to the highest standards of precision. With the help of high-performance rolling machines, our specialists will help you turn parts from flat to cylindrical and conical in the shortest possible time. Sheet metal rolling involves cold working of the sheet metal, through which the metal is shaped, taking on curves. The rolling process is essential when manufacturing certain complex products which combine different radii of curvatures. Our rolling services cover both sheet metal rolling and rolling operations for round pipes with a diameter of 20 mm, 40 mm or rectangular pipes of various sizes. For more information about the technical aspects of our rolling services, please contact us by filling in the online form.

Request for a quote

EUGEN LÄGLER GMBH

Germany

The efficient solution for commercial areas and public buildings, such as sports or industrial halls. The SUPERHUMMEL is the first choice for the efficient sanding of large areas due to its powerful motor and its extra wide sanding drum. The SUPERHUMMEL stands for top sanding quality combined with a maximum area capacity. It is very user-friendly - easy to operate and at the same time to maintain. Both, changing the sanding belt and dismantling the machine, are extremely simple. The optimal dust extraction and the robust construction of the machine are a matter of course. Applications with the SUPERHUMMEL: The high-performance floor sanding machine with 300 mm (approx. 11.8”) sanding drum width has especially been designed for the efficient treatment of large-scale wooden floors, e.g. commercial areas and public buildings. The SUPERHUMMEL equipped with the hard rubber drum ensures an even removal on softwood floors with strong knots.

Request for a quote

STATEC BINDER GMBH

Austria

The CERTOPAC, a fully automatic high-performance bagging machine, packs any type of free-flowing bulk material in pillow bags and gusset bags with a filling weight between 5 kg and 80 kg. Thanks to its high speed, this open-mouth bagging machine can fill up to 1500 bags per hour. Because of the high flexibility of the packaging machine, bags made of woven PP, PE and paper can be processed. Furthermore, the CERTOPAC stands out due to its easy accessibility and high reliability. This high-performance packaging machine is also available as CERTOPAC-S and CERTOPAC-L in addition to the “standard version”. The differences between the variants are the bag magazines (rotating bag magazine or push magazine), the different filling weights and sizes of the bags. Furthermore, the CERTOPAC can also be completely made of stainless steel and equipped for powdery products.

Request for a quote

STATEC BINDER GMBH

Austria

The SYSTEM-T fully automatic Form-Fill-Seal (FFS) packaging machine combines high quality packaging from a PE tube with high production capacity and is therefore ideal to be used in a wide range of industries including petrochemicals, fertilizers, animal feed, food,... Due to the high flexibility of the FFS packaging machine it can be adapted to different customer requirements. For example, pillow bags and gusset bags can be produced with or without carrying handle and a filling weight between 5kg and 50kg. Additional perforation of the bags is also possible. The SYSTEM-T stands out due to its modern design and a very sturdy and compact construction. Accessibility, generous clearance, long maintenance intervals and low maintenance costs were of major importance in the development of this machine. For example, the large doors offer easy access to all areas and important parts and cable connections are protected from corrosive and aggressive dust by stainless steel housings.

Request for a quote

STATEC BINDER GMBH

Austria

The PRINCIPAC is a fully automatic high-performance bagging machine for open-mouth bags and, with up to 2000 bags per hour, it is one of the fastest in the world. The PRINCIPAC is characterized by high performance and flexibility. Both pillow bags and gusset bags with a filling weight of 10 kg to 50 kg can be processed. The bags can be made of woven PP, PE and paper. This fully automatic open-mouth packaging machine is ideally suited for any type of free-flowing bulk material and with additional equipment such as a dustproof filling spout also for powdery products. Depending on customer requirements, the high-performance bagging machine can also be made entirely of stainless steel. Further options enable the PRINCIPAC to be optimally adapted to customer requirements.

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

high performance internal coating machine for aerosol cans and bottles

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. High-performance placement machines by ASM with short setup times and high flexibility form the backbone of our automated SMD placement systems. Our services also include assembly of THR components (pin-in-paste technology). Extensive monitoring systems and built-in cameras ensure high precision in the placement process.

Request for a quote

RCP RANSTADT GMBH

Germany

Single-use wet wipes are being employed increasingly frequently for everyday use. We manufacture all types of wet wipes, whether for everyday use or for special applications We developed the wet wipe in a sachet as long ago as 1960. Since 1979, we have produced moist lens cleaning wipes – as the first in this field. At present, we have the most efficient packaging machines for the production of individually packaged wet wipes. Our high-performance machines reach capacities of more than one million units per day. Based on our over 50 years of experience in the manufacture of wet wipes, we have access to an almost unlimited variety of film qualities, sachet formats, cloth qualities, filler products and appropriate secondary packagings.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quote

STATEC BINDER GMBH

Austria

The Twin Version of the open-mouth bagging machine combines two bag placers and two filling stations in one machine. Two STATEC BINDER high-performance net weighers ensure that the product is precisely dosed and weighed. When the required weight is reached, the weigh hopper opens and the product flows into the attached bag at the filling spout. A high-performance bag closing machine enables fast sewing, sealing, or gluing of the bags. The high performance of the Twin Version is achieved by always separating two bags simultaneously, transporting them to the pick-up station, fixing them onto the filling spout, filling them, and placing them on the conveyor belt. The bags are then transported one after the other to the bag closing machine. For example, the PRINCIPAC-Twin can handle up to 2400 bags per hour with a filling weight between 10 kg and 50 kg.

Request for a quote

STATEC BINDER GMBH

Austria

The high-performance sewing machine from STATEC BINDER stands for precise and reliable bag sealing of woven PP, paper or PE bags. Two different variants can be used for sewing the bags. On the one hand there is the straight-line bag infeed, in which the bag is fed to the sewing head by means of a belt drive and then sewn at the upper end. The second variant is the bag edge folding, in which the bag is folded at the upper end when it is pulled in and then sewn. In order to change from one system to the other, it is only necessary to replace a simple device. The bag to be sewn is fed to the sewing machine via one of the two variants mentioned above. Depending on the sewing speed and performance, the stitch length is between 7 and 12 mm. A cutter at the end cuts the thread. The sewing head is driven by a motor with frequency converter. A big advantage over the drive via belt pulleys is a more precise adjustment of the speed.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine provides maximum economic efficiency at treatment of big batch volumes at high throughput! The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. At any time, this machine is ready for upgrade to automated application, from the automatic loading & deloading of the machine up to a complete full automated feeding & forwarding system. For industry 4.0 demands, the E90 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum-only deflashing), suitable for special applications only.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine is the optimal solution for mid-sized batch demands at fast throughput times! The E 40 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. For industry 4.0 demands, the E40 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum only deflashing), suitable for special applications only. mid-sized batches > fast throughput times > E40

Request for a quote

ILK IHRACAT AS.

Turkey

At steeling.net, we manufacture high-quality recycling machine blades designed for superior performance and longevity. Using advanced laser cutting, CNC bending, and precise welding techniques, our blades are crafted to meet the rigorous demands of recycling processes. These blades are engineered for optimal cutting efficiency, ensuring smooth and effective material processing. Made from robust materials, our recycling machine blades resist wear and tear, providing a reliable solution for your recycling needs. Customizable to fit various machine types and specifications, our blades ensure seamless integration and maximum productivity. Trust steeling.net for durable and high-performance recycling machine blades that enhance the efficiency and reliability of your recycling operations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The MPO-50M machine carries out quick preliminary cleaning of grain , legumes, oilseeds and industrial crops, corn, sorghum, rapeseed, sunflower seeds and grass. Designed for operation as a part of stationary production lines of grain cleaning complexes. Preliminary cleaning of grain in MPO-50M is carried out according to two main parameters - size and aerodynamic properties . The advantages of MPO-50M are that it is a universal high-performance machine for quick pre-cleaning of any grain or seeds with a moisture content of up to 70%. MPO-50M can easily cope even with the cleaning of grain heavily clogged with straw and other impurities. High speed of operation increases production volumes per unit time and allows you to quickly move from the stage of preliminary preparation of raw materials to the next stage in order to better preserve seeds and grain, prepare them for drying and active ventilation, increase the efficiency of subsequent cleaning.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

High-Performance Plasma Cutting Machine: Built to handle harsh environmental conditions, suitable for on-site operations with a generator or in a workshop environment. Starting: Innovative and advanced arc starting without HF. Performance: Innovative and advanced electrode and nozzle design. Longer Lifespan: Innovative and advanced design increases the life of consumables. Faster: higher travel speeds and sheet thickness. Flexible: multiple torch configurations and different materials: carbon steel, stainless steel, aluminum and many more. Concentrated plasma flow: less heat input, less distortion. What's included: 2 m input cable 7.5m manual cutting torch Earth and cable clamp Air Connection Kit Cutting Torch Consumables Kit

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

High-Performance Plasma Cutting Machine: Built to handle harsh environmental conditions, suitable for on-site operations with a generator or in a workshop environment. Starting: Innovative and advanced arc starting without HF. Performance: Innovative and advanced electrode and nozzle design. Longer Lifespan: Innovative and advanced design increases the life of consumables. Faster: higher travel speeds and sheet thickness. Flexible: multiple torch configurations. Different materials: carbon steel, stainless steel, aluminum and many more. Concentrated plasma flow: less heat input, less distortion.

Request for a quote

FILMEX PACKAGING KFT.

Hungary

A double layered film on a roll, made of food-safe, water- and dust-resistant material that can be recycled infinitely. It is non-toxic, extremely lightweight, easy and quick to process / seal and, despite the low film thickness, highly tear resistant, waterproof and temperature tolerant. We manufacture our products with a high degree of dimensional and thickness stability, using virgin or even recycled materials, adapted to modern high performance packaging machines.

Request for a quote

ASTRA LT AB

Lithuania

Punching service with high performance production CNC machine. Main properties: max. punching force – 220 KN; max. sheet thickness - 6 mm; max. sheet dimensions without reposition - 1500x3000 mm; max. sheet dimensions with reposition 1500x7000 mm; max. sheet weight – 180 kg; tolerance for repositioning - +/-0,05 mm; thickness of the punching sheet – 0,6÷6 mm.

Request for a quote

PHILPLAST LTD.

Bulgaria

Our tooling engineers and designers have extensive experience in creating various blow molds and injection molds. Our in-house tooling department produces molds for most plastic articles made in Philplast as well as molds for use outside our company. We can design, produce and issue technical documentation before the mold making, or we can make molds from 3D documentation provided by the client. In our tooling production we use new fully equipped high-performance CNC machines. The maximum size of our blow molds is for articles up to 20 liters in volume. The maximum dimensions for our injection molds are 546 x 896mm with a maximum weight of 2,500kg. All molds made to be used in Philplast are thoroughly tested on out machines to ensure their perfect quality.

Request for a quote

O.M.C. COLLAREDA S.R.L.

Italy

High performance gravity machine, no vacuum required, no particular installation sites.

Request for a quote

PROGRES CNC

Poland

The VCN-430A vertical machining center brings advanced technology, value and productivity to a wide variety of machining applications. With the lowest cost of ownership in the industry, the machine features a single table design and ample axis travels for processing one or multiple parts in single machine setups. A standard high-performance spindle allows the machine to achieve an effective balance of speed and torque for the fast and heavy-duty cutting of a wide variety of materials.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The flexible PC-controlled high-performance circular sawing system PSU 450 A is designed for the utmost cost-effective production of small and large quantity runs. • The PSU 450 A features up to three servo-motorized axis to ensure a precise positioning with regard to length, mitre angle setting and output gripper unit • The material to be cut off is held by means of the output gripper unit. After the cut, the cut piece is removed from the working area in axial direction and put at a defined place. • Extraordinarily short cycle times due to the hydraulicallycontrolled saw stroke • A standard feature in the saw is an innovative, dynamic saw drive technology that ensures premium cutting results.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Due to its revolution speed and high performance this quality machine can be used diversely, e.g. with a collet for tools of 3–8 mm diameter. A very impressive machine that stands for endurance and strength whilst meeting all ergonomic and weight requirements. A version with a pair of supports for hard applications is also available.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 52 is intended for the simultaneous 5-axis machining of workpieces weighing up to 2000 kg - with unbeatable accuracy and precision. Parameters that always represent a challenge for the machine dynamics. HERMLE has overcome these challenges by developing and designing a precise and high-performance machining centre. The C 52 is the successor of the extremely successful C 50. The C 52 machining centre: A flexible all-rounder with a large working area and minimum footprint. The tool magazine of the C 52 is also integrated and can be extended to 325 pockets using an additional magazine. The C 52 sets new standards: These standards are particularly valued in demanding applications, for instance in the medical, aerospace and automotive industries. In short: wherever the highest precision and maximum efficiency are required. Milling and turning in one clamping - the MT series with the model C 52 U MT dynamic.

Request for a quoteResults for

High-performance machining - Import exportNumber of results

99 ProductsCountries

Company type

Category

- Woodworking - machinery and equipment (17)

- Machine tools, metal machining - parts and accessories (11)

- Packing and packaging - machinery and equipment (6)

- Mechanical engineering - custom work (4)

- High-pressure cleaning machines (3)

- Ink jet printing (3)

- Laser - cutting and welding machines (3)

- Sawing machine tools (3)

- Blades and knives, industrial (2)

- Brick-making - machinery and equipment (2)

- Concrete mixers (2)

- Cutting - steels and metals (2)

- Harvesting machinery and equipment (2)

- Import-export - mechanical engineering (2)

- Lubricants, industrial (2)

- Machine tools - metal machining (2)

- Milling - steels and metals (2)

- Paper and cardboard manufacturing - machinery and equipment (2)

- Rubber - industrial machinery and equipment (2)

- Adjustment - machine tools (1)