- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high vacuum systems

Results for

High vacuum systems - Import export

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our optical filters and other coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, vacuum coating

Request for a quote

SÜD-OPTIK SCHIRMER GMBH

Germany

We produce our anti reflective coatings with the most modern high vacuum coating systems both according to customer specifications and according to our own layer design, anti reflective glass, AR coating

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

High-vacuum heat-treatment furnaces with integrated pressing unit and power-regulated resistance heater elements (Hot Press). Used for diffusion bonding and forming processes under high vacuum conditions as well universal use for thermal treatments and processes where particularly demanding requirements and sophisticated materials are involved.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

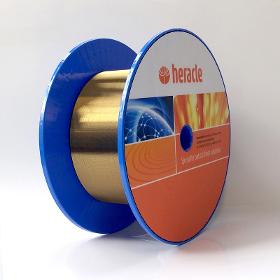

HERACLE GMBH

Germany

heracle developes and produces specialty optical fiber with metal coating for application in harsh environments. Fiber types include Mutimode fiber with step or graded index profiles and Singlemode fiber. All fiber fiber types can be offered with either Gold or Aluminum coating. The pure fused silica step index multimode fibers (SIMM) are optimised for applications in the UV/VIS and VIS/IR wavelengths. The graded index Multimode fiber is designed to operate at 850nm and 1300nm. The Singlemode fiber is specified accoring to according ITU-T G.652. Metal coated optical fibers are typically used under extreme conditions such as: - Aircraft, missile, rocket, turbine & jet engine monitoring; - Radiation, caustic & corrosive environments - Material fatigue sensing applications - High power laser delivery systems - Ultra high vacuum applications

Request for a quote

HERACLE GMBH

Germany

Our gold coated fiber is available for both wavelength ranges: from UV, VIS up to infrared wavelength ranges. The fiber offers excellent protection against chemical corrosion & mechanical stres and is capable of withstanding extreme temperatures and harsh environments. The fiber can be terminated directly onto the coating for hermetically sealed assembly. Our Gold coated fiber has very low outgassing of volatile components. We perform 100% stringend test procedures according to international standards. Typical applications are typically for extreme conditions such as: • Aircraft, missile, rocket, turbine & jet engine monitoring • Radiation, caustic & corrosive environments • Material fatigue sensing applications • High power laser delivery systems • Ultra high vacuum applications

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Vacuum degassing / outgassing With the aid of vacuum outgassing, unpleasant tastes or odors can be degassed and thus rendered tasteless. Altitude simulation For aircraft transport, it is essential to perform tests and simulations at a pressure <800 mbar, since in cargo holds, pressure equalization takes place, but cannot compensate for all fluctuations. Vacuum storage systems The safest way to store highly sensitive components is under vacuum. Under the vacuum environment, your components are protected from all external influences. Control and process control Our specially developed control program offers not only the possibility to monitor, but also to program and store various process sequences. High and ultra-high vacuum From the pressure range of rough vacuum to fine vacuum and ultra-high vacuum, we are able to meet your process requirements with our systems.

Request for a quote

EUROPE ZHAOHAN VACUUM PUMP CO., LTD

Hungary

Closed circulation vacuum system is consisted with liquid ring vacuum pump and compressor, liquid and gas separator tank, heat exchanger, instrument and valves, internal pipeline, and common base plate. The pumped gas enters the liquid ring vacuum pump/compressor from the pump inlet, after compressed by the liquid ring vacuum pump/compressor, the gas will enter to enter the gas-liquid separator together some of the working liquid. Inside the gas-liquid separator, the gas and liquid are separated, and the gas is discharged from the pump outlet, and the working fluid go from the heat exchanger and enter the liquid ring vacuum pump/compressor for recycling.

Request for a quote

VACUUM EL SYSTEM LTD.

Bulgaria

As a manufacturer of vacuum pumps and vacuum parts Vacuum El System provides a vacuum leak test in clean areas, using the most up-to date equipment and procedures. All welded flanges, fittings and chambers are cleaned carefully and inspected by Helium mass spectrometry in order to meet customer requirements. Our Leak testing equipment is able to achieve 10 ̄ ¹º mbar l/sec. Leak Test Certificates are available on request.

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Preparation of the material components under vacuum and injection into an evacuated mold.

Request for a quoteResults for

High vacuum systems - Import exportNumber of results

12 ProductsCountries

Company type