- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high scan rate

Results for

High scan rate - Import export

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

Defects to be examined in this application are very small, their size is often lower than 0.5 mm – hard to discover by human eye. Rework in the course of the production of the final product however, proves to be complicated and expensive. Large rolls with a diameter of 2 m and a length of 10 m are very difficult to remove and to reinstall. In order to avoid corresponding inconveniencies, it is essential to support the manufacturing process of the rolls themselves by a reliable quality control in the form of an automated final inspection.As the Quelltech Q6 laser scanner features an extremely precise resolution of 4096 Pixels/Profile at a high scan rate, this model proved to be able to meet the requirements and was mounted onto the positioning stage of the grinding machine. Furthermore, an industrial measurement computer was added, used for the analysis software of the point cloud. On the basis of this configuration, the entire roll surface could be recorded on a helical path.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The terrestrial 3D laser scanner Z+F IMAGER® 5016A combines compact and lightweight design with state-of-the-art 3D laser scanning surveyor technology - allowing the user to reach new levels. It's equipped with an integrated HDR camera, internal lighting and positioning system. All components of the terrestrial 3D laser scanner have been further developed and adjusted to the new design, resulting in even better scanning results and a more efficient workflow. With feature A, which stands for Advanced, the 5016 receives twice as high scan rate of up to 2.187 million pixels/second and more options for leveling the scanner. If the dynamic compensator is deactivated or the tilt is outside the defined range, the tilt is detected by the IMU of the Z+F IMAGER® 5016A.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

For listed buildings, there are regular new construction tasks. Often there are no adequate plans on the basis of which planning, modernization or renovation can be carried out. Due to the very high scan rate of more than 1 million measured values per second, range resolution in the millimeter range and a measuring accuracy in the mm range, even the capture of the finest structures and details is still possible with the 3D laser scanners from Zoller + Fröhlich. The 3D documentation is therefore the ideal prerequisite for reconstructions of, for example, design conditions or sensitive stucco work. The recorded inventories, damage, structures and details are recorded in databases and allow a faithful reconstruction of the entire object or of parts of the object at any later time.

Request for a quote

NEXTSENSE GMBH

Austria

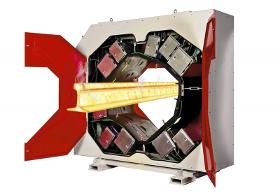

OSIRIS is a stationary, optical measuring system for inline control of dimensional accuracy and surface quality of long products. With state-of-the-art laser light cutting technology and high scanning rates, the OSIRIS systems offer a complete 3D reconstruction of the product. With the OSIRIS Hot version, up to 1,100 degrees hot long products can be analyzed. The measurement results are displayed in real time on the control terminal and thus allow early corrective action to increase throughput and product quality. The surface inspection function automatically detects and classifies deviations in the product surface (peeling, blow-outs, scoring, rolling etc.). In addition, profile cuts of the long product are simultaneously generated to check length dimensions such as width and height, various radii and angles. Different system sizes allow the measurement of large and small long goods.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZUMBACH ELECTRONIC AG

Switzerland

Thanks to the robust, dirt-resistant design of the Steelmaster, it is suitable for hot steel applications under production conditions with a lot of dirt and warm product and ambient temperatures. Properties Cutting-edge optics and laser scan technology Extremely high sampling rate Highest accuracy and stability; measurements independent of orientation Non-contact measurement of diameter and ovality Suitable for measurements under harsh conditions Interfaces such as Ethernet IP, Profinet IO, Profibus DP and others Integrated web server in all processor versions. Benefits High operational reliability even under harsh conditions Heat resistant, thanks to integrated heat shield and water cooling Protective system using air purging unit and blower Very robust and durable design Extremely dirt resistant.

Request for a quote

LLA INSTRUMENTS GMBH & CO. KG

Germany

For the identification of larger particles such as plastic bottles, the fiberoptic multiplexed NIR spectrometer KUSTA1.9MPL-24 was developed for this application. Up to 64 tracks can be used for the plastics analysis on a conveyor belt up to 2800mm. High scan rates can be performed of up to 3m/s conveyor belt speeds. Equipment is also available: probe lines and calibration from 500mm up to 2800mm

Request for a quote

COGNEX CORPORATION

Germany

DSMax is the fastest and highest definition laser line 3D displacement sensor on the market for acquiring images and inspecting products in 3D. It is the only sensor that offers: — High scan rates (up to 18 kHz) at full measurement range — Maximum resolution images (2,000 profile points) — Fast high dynamic range (HDR) image These features make it the ideal solution for measuring and inspecting very small parts, such as electronic components, which can contain highly reflective or dark features.

Request for a quoteResults for

High scan rate - Import exportNumber of results

9 ProductsCountries

Company type