- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high pressure electric pumps

Results for

High pressure electric pumps - Import export

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

SPX FLOW EUROPE LTD - THE NETHERLANDS

Netherlands

21,750 PSI (1,500 BAR) HIGH PRESSURE ELECTRIC PUMP The SPXFlow PE8 is a very high pressure pump that incorporates proven design for reliable operation. It is based on proven pump design for reliability in rugged bolt tensioning applications. Quality means Lower Life-Cycle Costs: Over 100,000 cycles Continuous duty up to 122˚F (50˚C) ambient Proven design = Proven reliability Enhanced Usability: Light Weight and portable: 45.5 lb (20.6 kg) [without oil] Quick Release, removable control pendant (15 ft / 5 m) Removable 4" (100 mm), calibration-capable, gauge Universal Motor for reduced voltage applications (up to -20% nominal voltage) SPX Tensioners are designed to daisy-chain together so multiple tools can run off one pump Compact design fits into tight spaces Designed with Safety in Mind: Easily adjusted pressure regulator (relief) valve

Request for a quote

TURKOGLU

Turkey

Body: ASTM A-536 Cast Iron / Valves : Bronze Surface covered with Teflon, Stainless steel Trim Set / Pilot control valve and system: Bronze ASTM B62 and Stainless steel 303 inner parts ** Connection Type: Flanged / Pressure :16-25 Bar / Working Temp.: +4ºC , + 80ºC *** This valves using for the preventing damages which cause from the pressure in fire pump systems. Generally fire protection systems use the diesel pumps and electrical motors. In that systems relief valves are preferred. **** Application Areas: In systems which has diesel or electrical high pressure fire fighting pumps.

Request for a quote

SOJET, LDA

Portugal

High-pressure pumps with 3 high-performance Leuco/Hawk pistons designed especially for car washing. Various models and special versions designed for carwhash with different pressures and debits.

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

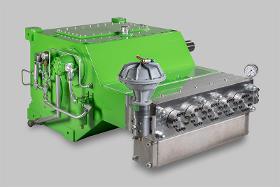

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

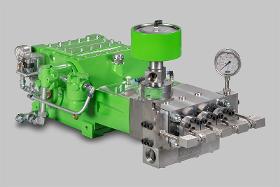

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

ZBKIT LLC

Russia

One-plunger pumping units PT 1.1 with capacity up to 8 m3/h and pressure up to 40 MPa Three-plunger pump units according to API 674 (3-d edition) PT 1.3 and PT 2.3 with a capacity of 0.2 m3/h to 60 m3/h and pressure up to 80 MPa Five-plunger pumping units Pumping units are designed for pumping various liquids, including chemically active ones, with temperatures from -15 ° С to + 450 ° С, kinematic viscosity of not more than 8 cm / s, with the content of solid non-abrasive particles up to 0.2% by weight and size up to 0.2 mm.

Request for a quote

HIPRUN POMPA VE CNC EKIPMANLARI

Turkey

Double filtration system is used in our high pressure coolant sytems. They are easily removable and cleanable. On the other hand, especially the main feature of this system is not to be obligated to stop machine during cleaning and changing filter. One filter can be operated with machine while another is been cleaning. This will provide you the time saving during filter change Multiple Manifold Block with 4 outlets is provided as standart in this model. However, it can be manufactured over 4 outlets depending on your requirements at your machining process. HP2 High Pressure Coolant Units are used as mobile station. They have wheels under units and you may easily move it where you prefer them to be placed at your workshop.

Request for a quoteResults for

High pressure electric pumps - Import exportNumber of results

12 ProductsCompany type