- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high pressure die casting

Results for

High pressure die casting - Import export

BACA MAKINE LTD.

Turkey

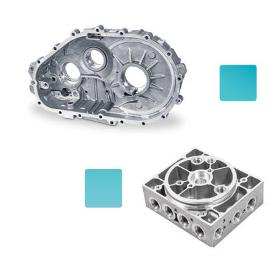

High pressure casting is a process in which molten metal is safely filled into the mold cavity under pressure. High dimensional accuracy greatly reduces machining work. High pressure die castings have a good surface finish, which is a basic requirement for coating. Molds have a long service life, reduce unit part costs, and more complex parts can be produced, thereby reducing the number of components required in an assembly.

Request for a quote

KOVINOPLASTIKA LOŽ D.O.O.

Slovenia

Foundry department ranks among the largest foundries in the region as we process 2000t of zinc alloys per year. High quality of casted components of zinc alloy grade ZAMAK 5 and ZAMAK 2. Technical precision assured with 18 high pressure die casting machines (Frech and IC) with locking force 40 to 200t.

Request for a quote

MODULUS METAL

Turkey

Modulus Metal has ISO / IATF certified die casting supplier base, mainly in aluminum high pressure die casting, and our partner suppliers are experienced in automotive, aerospace, agricultural and industrial machinery manufacturing for many years. Production capabilities: Up to 10 kg /piece Quantity: Mainly high volumes of production due to tooling cost Aluminum,As Cast,Wrought,COPPER,Aluminum Bronze, Brass, Bronze, Coated Copper, Copper-Nickel, Silicon Bronze,ZINC,Aluminum Alloy : Forming Die Alloy, General Casting Alloy, Pressure Die Casting Alloy, Slush Casting Alloy, Wrought,Commercial Purity,Copper Alloy : Pressure Die Casting Alloy , Wrought

Request for a quote

TRIBO-CHEMIE GMBH

Germany

Tried and tested release agent, which is qualified for glueing and welding of structural castings Temperature Range 130 °C to 350 °C Alloy Al, Mg, Zn Properties and Advantages • ideally suitable for conventional as well as micro-/minimal spraying • approved for glueing, welding, painting and powder coating • no build-up • die wetting already at lower temperatures

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD P is a cold curing casting resin for the production of porous moulds, slabs and blocks for the ceramic industry. It is a porous and high-strength plastic, which is well-suited for high pressure casting applications. ALWA MOULD P can be used in various areas of the tableware and sanitary ceramics, technical ceramics, plastic mould procedure as well as various filtration processes. The high stability and defined porosity of the material allows highly accurate mould surface reproductions. With ALWA MOULD P various geometric moulds for filtration processes of suspensions can be produced. ALWA MOULD P can be used for ceramic slip pressure casting procedures. In this procedure, water is removed by a filtration process of a clay suspension (slip), so that an increasing clay layer is built on the mould wall over time. The moulds, slabs and blocks of ALWA MOULD P are easily machinable (e.g., drilling, milling).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METAL TECHNOLOGY GROUP

Bulgaria

Machine low pressure die-casting of aluminium parts, counter pressure die-casting and high pressure die-casting with crystallization (“liquid, semi-liquid” stamping) of AlSi based alloys in accordance with EN 1706 6

Request for a quote

OMEGA AIR

Slovenia

HF filters are designed for high efficient removal of solid particles, water, oil aerosols, hydrocarbons and other vapours from compressed air systems. To meet the required compressed air quality appropriate filter element (B, P, R, M, S, A) must be installed into filter housing. Optional external condensate drains should be used for efficient condensate draining from filter housing.

Request for a quote

OMEGA AIR

Slovenia

HF O2 series of filter housings have been specifically developed for high efficient removal of solid particles from compressed Oxygen applications.

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Facts: Freely rotating and swivelling safety hook for suspension, adjustable Housing and housing cover of high-strength pressure-cast aluminum Cable drum of high-strength pressure-cast aluminum Closed ball bearings on both sides High-strength, encapsulated special suspension spring High-strength steel cable • Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Infinitely variable load setting via endless screw Patented freewheel protects against overrotation when the spring is released Available with and without manual lock.

Request for a quote

CARL STAHL KROMER - GERMAN MADE SPRING BALANCERS

Germany

Special tool balancer with double cable for extra safety. Facts: Dual-cable design Freely rotating and swivelling safety hook for suspension, adjustable Housing and housing cover of high-strength pressure-cast aluminum Cable drum of high-strength chill-cast aluminum Closed ball bearings on both sides High-strength, encapsulated special suspension spring High-strength steel cables Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Infinitely variable load setting via endless screw Patented freewheel protects against overrotation when the spring is released

Request for a quote

ISOTEK CNC TAKIM TEZGAHLARI OTOMOTIV (HPT)

Turkey

Our new light weight pump for demanding truck hydraulics for operating, for example, loader cranes, hooklifts, etc. Displacement range 12-108 cm3⁄rev and working pressure up to 400 bar. Direction of rotation is easy to change by turning the connection cover. We use 2 types of seals. first type fitted with extra heat-resistant seals (Viton) to withstand higher temperatures when mounted on an engine power take-off. These type of seals used in high temperatures region. The second type is normal seals which can withstand cold weather. We use the best bearings which stand high heat temperatures and high speed rotation.

Request for a quote

TAVRIAN CASTING COMPANY TALKO

Ukraine

Aluminum casting workshop: producing castings by means of die-casting, low pressure casting and gravity casting. The Workshop capacity is 1500 tons of good cast per year. Aluminium cookware casting workshop: producing cookware with non-stick casting. Machine-assembly workshop: manufacturing of machined parts and fabricated assemblies. Alloys manufacturing subdivision: recycling of aluminium wastes and dross. Manufacturing of aluminium secondary alloys.

Results for

High pressure die casting - Import exportNumber of results

13 ProductsCountries

Company type

Category

- Filters, liquid (2)

- Handling - Machines & Equipment (2)

- Aluminium alloys (1)

- Cements, special (1)

- Foundries - machinery and installations (1)

- Foundries, aluminium (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Pumps (1)

- SMALL METAL PARTS (1)

- Steels and metals - welding and brazing (1)