- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high performance bearings

Results for

High performance bearings - Import export

IGUS® GMBH

Germany

iglidur® flange bearing d1 [mm]: With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. When to use iglidur® flange bearings? When you want a screw flanged bearing When a clip bearing solution is not satisfactory as a sheet metal feedthrough When there is a housing with very rough tolerances When the tight fit of a press-fit bearing is not sufficient as an axial securing When not to use them? When an additional angle compensation is required igubal® flange bearing When a screw connection is not possible iglidur® clip bearing When a large guide length is necessary iglidur® G General features With this design it is possible to use the iglidur® high-performance bearings where housing bores with no precise tolerances are possible. The design enables high loads with minimum demand on the precision of the housing. iglidur® maintenance-free flange bearings are available in four materials - iglidur® G, iglidur® J, iglidur® X and iglidur® A180. Thus, with this design, a very wide range of applications - from the universal bearing through the highest wear resistance or temperature resistance (up to +250°C) up to FDA-compliant bearing solutions - can be covered. Installation Dependent on the stressing capacities, various mounting types are used. For low radial loads, it is enough to mount the iglidur® flange bearing with just two screws on a surface. For higher radial loads, it is advisable to support the iglidur® flange bearing in a bore on the reinforced side in the load direction. Large tolerances are permitted for this bore, as it is only to additionally support the iglidur® flange bearing. In order to support still higher radial loads, the iglidur® flange bearing can be press-fitted with the longer side in an H tolerance bore. The additional screw connection secures the firm seating of the bearing in the housing. For the mounting of the iglidur® maintenance-free flange bearing, no special tools or devices are necessary. The alignment of the bearing in multiple mounted shafts is easily possible at the installation. Available materials: iglidur® G, iglidur® A180, iglidur® J and iglidur® X The mounting of the iglidur® flange bearing: Simple and safe iglidur® flange bearing d1 [mm]:

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction, rolling and pivoting bearings, splined shafts, knockout spindles and sliding surfaces of all kinds under normal loads and all sliding speeds common for grease lubrication Supports sealing of bearings and corrosion protection Advantages and benefits Highly effective due to optimum combination of components Good resistance to pressure and water Fewer downtimes and repairs as a result of reduced wearing Resistant to ageing and oxidationFor highest effectiveness, carefully clean the lubrication point, for example with OKS 2610/OKS 2611 universal cleaner. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value < 50,000) and their housings should be filled completely. The bearing and machine manufacturer's instructions should be observed.

Request for a quote

PEEKCHINA CO., LTD.

China

Bearing PEEK Material Performance Experience the superior performance of composite PEEK plain and sleeve bearings. These high-performance bearings combine the strength and durability of composite materials with the low-friction properties of PEEK, resulting in exceptional wear resistance, self-lubrication, and extended service life. Whether it's in demanding industrial applications or precision machinery, these composite PEEK bearings deliver reliable and smooth motion, ensuring optimal performance and reduced maintenance.

Request for a quote

PEEKCHINA CO., LTD.

China

Engineered with precision and durability in mind, the PEEK thrust washer swivel is a high-performance bearing component that excels in rotary applications. Made from PEEK (polyetheretherketone), a robust polymer material, it offers exceptional low friction and high wear resistance. This self-lubricating swivel ensures smooth and efficient operation, reducing frictional losses and promoting optimal performance in industrial machinery. With its corrosion-resistant properties, it guarantees long-lasting durability even in harsh environments.

Request for a quote

NORELEM FRANCE

France

Ceramic bearings Si3N4. Bearing cage PTFE. For most applications Si3N4 is the preferred material for ceramic bearings. Silicon nitride bearings are light, very hard and highly wear resistant. High and ultrahigh performance bearings are used in e.g. aerospace technology, metal production industries (high application temperatures), machine manufacturing, chemical industries (chemically aggresive substances), pharmaceutical and medical industries, semiconductor and biotechnology (clean room enviroments which may not be contaminated by lubricants). On request Special version with PEEK ball cage. Without ball cage.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

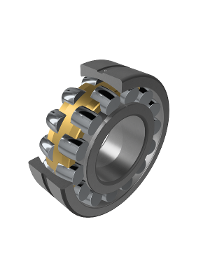

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

ALKIM PETROKIMYA

Turkey

It is red colored grease containing high quality mineral oils with calcium soap. It is developed to be used in systems in which water and moist are inevitable and it also has a wide range of application areas. It provides quick and e ective lubrication in various application areas where operating temperature is not high. • It is recommended to be used in grease lubrication processes of ball and roller bearings and hydraulic turbines, temperatures of which does not exceed 70 °C. • It provides high performance in lubrication of bearings operating in chassis and watery medium. • It has excellent resistance against water. It is not washed and does not flow. • It provides excellent protection against corrosion. • It reduces abrasions, and thus reduces maintenance costs.

Request for a quote

ALKIM PETROKIMYA

Turkey

It is red colored grease containing high quality mineral oils with calcium soap. It is developed to be used in systems in which water and moist are inevitable and it also has a wide range of application areas. It provides quick and effective lubrication in various application areas where operating temperature is not high. • It is recommended to be used in grease lubrication processes of ball and roller bearings and hydraulic turbines, temperatures of which does not exceed 70 °C. • It provides high performance in lubrication of bearings operating in chassis and watery medium. • It has excellent resistance against water. It is not washed and does not flow. • It provides excellent protection against corrosion. • It reduces abrasions, and thus reduces maintenance costs.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Deep Groove Ball Bearing 6005-2RSH SKF Main Features: This high-performance bearing, made from bearing steel, features superior resistance with contact sealing on both sides, which prevents contaminants from entering and retains lubricant. Designed to support radial and axial loads in both directions, with low friction, optimized to reduce noise and vibration, allowing a high rotational speed. Dimensions: Hole Diameter: 25 mm. External Diameter: 47 mm. Width: 12 mm. Performance: Basic dynamic load of 11.9 kN and basic static load of 6.55 kN, with a limit speed of 9,500 r/min. Properties: Single row design with CN radial internal clearance, tolerance class Normal, rolled metal cage, no lubrication required. Product Detai

Request for a quote

SB-TRADING (BVBA)_M

Belgium

Heavy density 9.75g/cm3. 2. Customized indium powder size 80mesh, 100mesh, 200mesh, 325mesh, 500mesh. 3. High purity virgin Indium metal 99.995% up. 4. Wide range of applications like the transparent electrode(ITO film), solder in electronic industry, Low melting alloy, bearing for high-performance engine, and the seal in low temperature, etc.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Lubcon offers an assortment of customised solutions, specially designed for the lubrication of high speed spindle bearings. Our high performance greases feature an optimum base oil viscosity and mechanical thickener stability. These products meet the demanding requirements in modern high-precision machine tools with speed factors of up to 3 Mio. n x dm.

Request for a quote

TURBOWORKS LTD

United Kingdom

During the turbo rebuilds, we offer an opportunity to enhance both reliability and performance through turbo upgrades. Our array of turbo upgrades encompasses options such as billet wheels, high-performance bearings and seals, larger turbines, ball-bearing conversions, precision machining of turbocharger housings, turbine blade optimization, meticulous porting and polishing, staggered seals, innovative hybrid solutions, and beyond. It's noteworthy that all of our upgraded turbochargers are furnished with enhanced bearings and seals as a standard feature, and all of this is offered at highly competitive prices.

Request for a quote

MATTES KG

Austria

Heavy density 9.75g/cm3. 2. Customized indium powder size 80mesh, 100mesh, 200mesh, 325mesh, 500mesh. 3. High purity virgin Indium metal 99.995% up. 4.Wide range of application like the transparent electrode(ITO film) ,solder in electronic industry, Low melting alloy, bearing for high performance engine , and the seal in low temperature,etc.

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

ETK BEARING CO.,LTD

France

ETK mainly produce good quality of pillow block bearing in China,with more than 20 years experiences ,can produce both housing casting & bearing production . ETK has its own R& D center and testing Lab.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

Based on our many years of experience in developing and manufacturing high-quality machine components, GMN has specialized in the area of high-precision ball bearings as well as the production of high-performance and long-lived deep groove and spindle ball bearings to meet – or even exceed – the highest precision classes P4 and ABEC 7. Certification under international standards ensures the highest precision in the development and manufacturing of GMN ball bearings and guarantees constant, outstanding qualities related to speed suitability, stability and longevity. The broad product range includes a large selection of standard solutions as well as requirements-tailored special designs.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quoteResults for

High performance bearings - Import exportNumber of results

22 ProductsCountries

Category