- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat treatment plants

Results for

Heat treatment plants - Import export

UNITED PROCESS CONTROLS GMBH

Germany

More than SCADA. The Protherm 9800 is a modular production management software for supervising, controlling and archiving heat treating processes and heat treatment installations. It delivers everything to optimize the performance and efficiency of a heat treatment plant operating a variety of furnaces as well as automatic handling machinery. By combining process control, equipment integration, and automation capabilities, the Protherm 9800 provides a comprehensive approach to plant wide supervisory control and management. FEATURES • Highly detailed visualization of all furnaces and connected devices • Scalable set of functions • Module for fully automated production system/cell (lights-out) • Easily implementable interface to existing planning and production systems • Possibility of simulating heat treatments

Request for a quote

PERO AG

Germany

The R5 units from PERO are able to clean large quantities as well as large workpieces in a highly efficient manner with short cycle times. Thanks to its large-capacity processing chamber, the R5 is particularly popular with companies in the automotive and aerospace industries, as well as those of forming plants, heat treatment specialists and contract cleaners where high cleaning capacity is a must. Suitably dimensioned tanks guarantee excellent degreasing and cleaning results in single-shift and multiple-shift operation, even at high throughput rates. Cleaning Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Highlights - High flexibility - Maximum throughput - Unrivalled cleaning quality Availability Available as 1- and 2-bath unit with loading of the unit via - Hall trolley - Pallet truck - Automatic charging unit

Request for a quote

PERO AG

Germany

The R4 from PERO is able to clean large quantities of parts as well as large workpieces in a hgihly efficient manner with short cycle times. With its high cleaning capacity, the R4 meets the needs of companies in the automotive and aerospace industries, as well as those forming plants, heat treatment specialists and contract cleaners. Thanks to customised parts carriers and logistics concepts, the R4 offers reliable degreasing and cleaning results for emobility suppliers. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Suitable for 1/2 EURO wire mesh boxes Suitable for largesize workpieces Efficient cleaning to high cleanliness standard Available as 1 and 2bath unit with loading of the unit via Hall trolley Pallet truck Automatic charging unit

Request for a quote

WESTLAKE EUROPE

Belgium

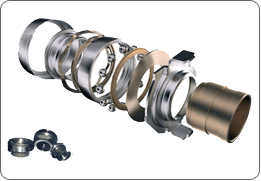

Complete range of release bearings produced in house. Produced to ensure optimum performance levels in line with OE standards. A range of Concentric Slave Cylinders, (CSC) also available. All release bearing components - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE specifications. Tests include over 1, 000, 000 actuations in the fatigue test.

Request for a quote

WESTLAKE EUROPE

Belgium

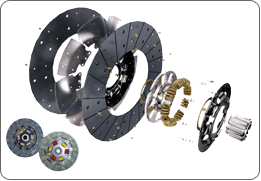

Design and production facilities for all types of car, light commercial and heavy commercial vehicle clutch plates. All friction materials used are non-asbestos, non-toxic and lead-free. Friction materials produced in house – Unique for a clutch manufacturer. Hubs, damper springs, retainer plates and components - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE specifications. Tests include overall plate parallelism, cushion deflection, compressed and relaxed thickness, spring rate and torque capacity/characteristics.

Request for a quote

WESTLAKE EUROPE

Belgium

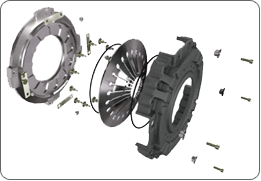

Castings for Pressure plates are produced in our own factory from high quality cast iron produced in accordance with the requirements of BS1452 and DIN1619. The material must be compact, devoid of blowholes and/or inclusions, crack free and uniform in hardness and texture. Cover pressings are produced using the most sophisticated press equipment available. Pressure Plates, Diaphragm Springs, Straps and all other components undergo strict analysis for chemical composition, tensile strength, hardness and microstructure. All components parts undergo rigorous inspection and measurement controls before entering the production areas. Diaphragm springs - Produced utilizing Japanese manufactured automatic heat treatment plant and computer tested against OE load specifications before assembly. Tests including clamp load, release load, pressure plate lift, finger height, stress and fatigue testing using the latest sophisticated test and inspection facilities.

Request for a quote

INSERTEC- INGENIERÍA Y SERVICIOS TÉCNICOS, S.A

Spain

Business lines Efficiency, profitability, circular economy, automation and safety: we provide integrated solutions for smelting, aluminium recycling and heat treatment plants. We understand the digitisation of plants as a living development that generates value and competitiveness in companies. We intervene at a global level from the engineering phase to the management and integral maintenance of the facilities. Services and Solutions Service is one of the values of our origin, it is part of our DNA. Our solutions and services cover all phases of the life of a smelting, aluminum recycling or heat treatment plant: engineering, equipment, automation, revamping... We carry out projects on an international scale.

Request for a quote

WIB SA

Switzerland

The 100 Cr6 steel rings manufactured by WIB are stabilized after hardening by annealing. As a result of this treatment, they can be used at temperatures of up to 150°C. They have a hardness of 60 to 64 HRC For applications operating at high temperatures or in order to reduce their sensitivity to shock loads, it is necessary to stabilize the rings at higher temperatures after hardening. It should be noted that such a stabilization will slightly reduce the hardness of the rings.

Request for a quote

ERATEC

France

Tissue drying Lamination Ironing Heat treatment rollers

Request for a quote

EXTRA FORGE D.O.O.

Slovenia

At our company, we offer comprehensive heat treatment services for both steel and aluminum products. Our team consists of expert associates who are leaders in their respective fields, ensuring top-notch quality and precision in every project. Additionally, we provide valuable consultation to help you determine the best available options or optimize processes to achieve your desired results efficiently.

Request for a quote

FRIGORTEC GMBH

Germany

Using the DEBUGGER method (heat treatment) from FrigorTec, the DEBUGGER DB18 has proven its effectiveness in killing insects, larva, and eggs, for decades. This method increases the air temperature to a range between 45°C and 60°C, and keeps it there, so that pests die off without using chemical substances, thus preventing damage to buildings and their fittings. A power distributor is required depending on the size of the installation site or the number of devices, and we recommend using one or more SCRAMBLER SC 6000s to save energy. Fields of application > Specially developed for large spaces, e.g., mills, bakeries, the food-processing industry > Often used in spice and coffee processing, as well as in the tobacco industry, muesli manufacture, and small animal feed production > Combine several DEBUGGER DB18s in very large rooms and halls

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A.’s forging and heattreatment division is capable of forging fittings (in a closed die) up to 4” 16 kg. The heat treatment furnaces and tanks are all certified to Norsok M650 and ASTM A991 standards and can treat any product that M.E.G.A. produces (large and small forgings, pipes and any other type of part).

Request for a quote

PLASTIC PALLETS UK / ASSOCIATED PALLETS LTD

United Kingdom

ISPM15 is an international standard for phytosanitary measures which is being progressively implemented throughout the world. Already some 28 countries have adopted the standard; a further 21 are in the progress of doing so and about another hundred countries have signalled their intension to bring the requirement to their national regulations. Countries which have signed up to ispm-15 are entitled to refuse entry at their frontiers to goods on wooden pallets, crates, spools or any other wood packaging unless it has been treated, marked and certified in accordance with their regulations. Associated Pallets Ltd has been providing a heat treatment which meets the demands of ISPM-15 and since the introduction of the plant some four years ago, has become experienced in all needs of the wood packaging producer and user.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Workpiece carriers guarantee safe workpiece handling - especially when it comes to reliably protecting sensitive workpieces from damage during transport and cleaning. We develop and produce workpiece carriers for high-precision and sensitive components. This means that the components are carefully embedded and positioned in customer-specific automation magazines in such a way that they are easily accessible for a gripper. In addition to being used with manual handling, the workpiece carriers are particularly suitable for customers with a high degree of automation. The tailor-made solutions are mainly used in production with automatic parts removal and in the material flow of the automotive supplier industry.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Our range of products includes welded charging aids such as guide grids, charge carriers, tempering baskets, traverses, basket inserts, wire mesh baskets, charging baskets, heat-resistant workpiece carriers, as well as hardening boxes for the heat treatment of steel or other metals. good strength properties at high temperatures Continuous operation in air up to approx. 1150 ° C with temperature changes up to approx. 1000 ° C perfectly suitable for heat treatment We use according to customer requirements .EN 1.4845 / AISI 310S .EN 1.4841 / AISI 314 Both materials are heat-resistant steel. Due to the higher chromium and nickel content and have a good resistance to oxidation. The good strength properties are still present even at higher temperatures. Both also have excellent chemical resistance up to 1100°C.

Request for a quote

ENKI WATER TREATMENT TECH. LTD

Turkey

enki’s package water treatment plant (Compact water unit) is used to treat surface water supplies for the removal of suspended solid, color and coliform with classical water treatment process. Our package water treatment plant is pre-assembled in factory and ready to the site. Package water treatment plant is a compact and standardized unit for treated water demands of the small communities and industries. The plant capacity can be increased by adding skid mounted containerized modules. Package water treatment plant is mainly consisting of : coagulation, lamella clarifier, filtration, chemical dosing unit , control panel auxiliary equipment. All equipment will be mounted in the container or in skid. At site will be mounted the piping and electrical cabling between container.

KAMYANKA MACHINE-BUILDING PLANT

Ukraine

Dimensions up to 600x600x900 mm, weight up to 800 kg. LPC (vacuum cementation) option. Hardening, heating in a gas environment and isothermal cooling.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Heat treatment plants - Import exportNumber of results

17 ProductsCountries

Company type