- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hard machining

Results for

Hard machining - Import export

EWS WEIGELE GMBH & CO. KG

Germany

EWS goes milling With its latest range of angular heads, EWS brings its trusted technology with new features to machining centres. The system range was presented to the public for the first time at EMO 2015. An elegant design houses high-performance technology, or to put it simply Precision meets Motion. Advantages: the smart solution for compensating for there not being a machining axis Machining hard-to-reach parts Centre boring stepless angle adjustment around the horizontal axis, with tangentially acting double cone clamp MR > 250 Nm Prerequisite: The prerequisite is a "stop block" on the machine. This prevents the entire unit from turning while simultaneously defining the position of the angel of rotation. Variations: basic duplex offset Request form: PDF

Request for a quote

STEEC

France

This modern machining technology offers a host of advantages over more conventional processes. STEEC makes available to its customers its know-how in micro drilling by spark erosion. The principle of this machining process is the same as for wire spark erosion, except that the tool used for cutting is no longer a wire but an electrode shaped according to the precision machining require. The part and the tool (electrode) are not therefore in contact with each other, in fact it is an electric arc formed between the electrode and the part that will machine the latter. This is also called sparking. The part must be necessarily be conducting to be able to be machined by this method and it is prerequisite for using this method. This absence of contact between the tool and the part makes it possible to machine very hard materials such as titanium for example.

Request for a quote

URBSCHAT-TOOLS GMBH

Germany

DE-BURRERS Specially developed for processing contours on CNC machines. To de-burr and chamfer metals and plastics. The de-burrers are also suitable for hard machining. Deburrer for contouring. Designed for use on CNC machines, especially for contour machining. For deburring and chamfering of metals and plastics. The de-burrers are also suitable for hard machining. Stocked by default is a point angle of 90 °. 4 - 6 mm de-burrer with 4 cutting edges, from 8 mm with 5 cutting edges.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

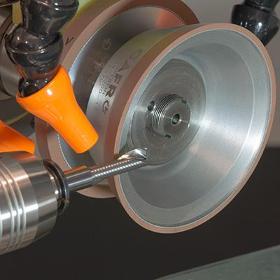

Our experts continually innovate and optimize our range of abrasives, making Tyrolit a trusted partner in the automotive industry and other sectors requiring precise gear grinding. We offer a comprehensive assortment of grinding wheels, cup wheels, and worm grinding wheels for generating, bevel gear, and profile grinding. Generating gear grinding uses a worm grinding wheel to continuously grind the desired profile into the workpiece. Unlike this, profile gear grinding machines each gear tooth individually, suitable for large gears. Tyrolit's vitrified-bonded profile grinding wheels have set industry standards, delivering exceptional cost-efficiency, process stability, and finish quality for gears of all sizes. With increased quality requirements, hard-fine machining of gears is essential. Tyrolit's special cup wheel line for bevel gears ensures exact topographies and pitches, offering high productivity, low thermal load, and maximum profile retention.

Request for a quote

WMC SINTERSTAR AG

Switzerland

WMC Sinterstar AG represents the company Mirka (Cafro) in Switzerland. Cafro diamond and CBN grinding wheels are characterised by innovative bonds and high cutting ability for machining hard metal, ceramics and steel. Cafro's core competence is the production of resin bonded diamond and CBN grinding wheels. Over the years, the company has also specialised in the manufacture of metal-, hybrid-, ceramic-bonded and electroplated grinding wheels and PCD/PCBN tools. Our employees will also find the optimal grinding solution for your company. We benefit from our own knowledge and experience as a carbide manufacturer.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Diamond grinding tools with VIB-Star core for technical ceramic components. Diamond grinding tools with cushioning plastic core system for machining very hard materials and technical ceramic components. Straight diamond grinding tools in vitrified bond for the machining of ceramic components require special damping, thus VIBSTAR is only available in certain dimensions on request. Damping + low weight Better surface finishes Longer lifetime Improved grinding ratio

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

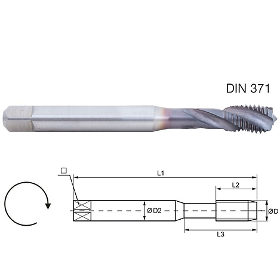

Thread standard: Metric, ISO DIN 13 Type: Machine tap Forma C, for blind holes, with spiral flutes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1000 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes. Materials: Nickel-based superalloys Incoloy 825, Inconel 718, Nimonic 75, Hastelloy X

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

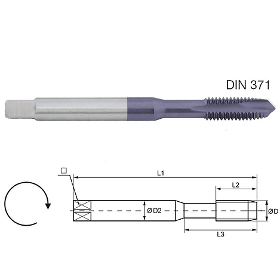

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For special alloys Material of product: HSSE PM Surface treatment: TiAlN For materials: Nickel-based superalloys (Incoloy, Inconel, Hastelloy,…), etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material (powder metal) and surface treatment for nickel-based superalloys. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

INTENSE SRL - TECNICHE DI ASSEMBLAGGIO

Italy

Thread standard: Metric, ISO DIN 13 Type: Machine tap Form B with spiral entry, for through holes Application: For high-tensile materials and stainless steel Material of product: HSSE PM Surface treatment: TiAlN For materials: High-tensile materials, Stainless steel, Alloyed heat-treatable steel, Cast iron, Aluminium cast and wrought alloys, etc* Tensile strength up to: 1200 N/mm2 Standard: DIN 371/376 Tolerance: ISO2/6H Special geometry, base material and surface treatment for Stainless steel. The TiAlN surface treatment increases the surface hardness (approx. 3300 HV), the sliding properties (friction coefficient: 0,25) and with high temperature resistance up to 800°C. It provides a better cutting performance and increased tool life time. The base material is powder metal (HSSE PM) with a higher hardness and toughness. Tap for machine use and through holes. The spiral point pushes the chips ahead and prevents clogging of the flutes.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Technical : Aluminium Hot Forging + Precision Machining Product Name : Aluminum Fastener Main Use : Auto Parts Technical parameter Technical Aluminum Hot Forging Fastener + Precision Machining Material: Al-6061 T6 Al-6063 Material Standard GB,ASTM,AISI,DIN,BS,JIS,NF Forging Weight 0.3kg~5kg Forging Dimension Tolerancez: CT8-10Grade Forging Surface Rough: Ra6.4 – 3.2 Rough of Machining Surface:Ra0.8-1.6 Support File of Format: ProE (.igs , .stp) , Auto CAD , PDF, Jpeg, Jpg, Png Heat Treatment: Quenching and Tempering , High Frequency Quenching Machining Equipment CNC Center,CNCs, Drilling Machine. Surface Finished Hard Anodizing Measure Tool: Micrometer, Caliper, Height Gauge,Screw Gauge Inspection First Checking , Checking , Final Checking QC Report:Material Report, Product Ddimension Inspection Report.

Request for a quote

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

The 90 series 48 spindle High speed rope braiding machine mainly used to produce RIC-RAC Lace, Piping Tape, Jacquard Tape, Elastic Band, Fibre Band, Various Ropes, Special Band and hoodie laces etc. Advantages: 1.Base casting was machined in machining center after aging treatment to ensure the flatness. 2. Panel uses ductile iron 800, was machined in machining center after aging-treatment to ensure its precision and wearing. 3. Core shaft rotor(impeller) uses ductile iron 600, firstly machined in machining center, high-frequency treatment on its surface to enhance its hardness, then machined by precision grinder. 4. Tolerance of fit between Spindle base and impeller is controlled within 0.03mm. 5. Rotor nylon pad was casted by nylon 66 with imported wearing-grease to make it last long.

Request for a quote

SHANGHAI DURA INDUSTRIAL CO., LTD.

China

The 13 spindles High speed braiding machine mainly used to produce flat type shoelace or tape, Piping Tape, Jacquard Tape, Elastic Band, Fibre Band, Various Rope, Special Band and so on. Advantages: 1.Base casting was machined in machining center after aging treatment to ensure the flatness. 2. Panel uses ductile iron 800, was machined in machining center after aging-treatment to ensure its precision and wearing. 3. Core shaft rotor(impeller) uses ductile iron 600, firstly machined in machining center, high-frequency treatment on its surface to enhance its hardness, then machined by precision grinder. 4. Tolerance of fit between Spindle base and impeller is controlled within 0.03mm. 5. Rotor nylon pad was casted by nylon 66 with imported wearing-grease to make it last long.

Request for a quote

FORMEX MAQUINARIA

Spain

WITH THIS MACHINE YOU WILL BE ABLE TO MAKE: Butter biscuits, almond doughs, curly biscuits, homemade biscuits, polvorones, perrunillas, mantecados, etc. •Uniform and fast production, avoiding punishing the dough or any alteration of its natural characteristics. •For medium and large productions, depending on the product and model. •Easy and quick change of moulds. •Intelligent production management by means of HMI panel, recipe programming. WIRE CUTTING AND MOULDS WITH A GREAT VARIETY OF SHAPES AND SIZES: For dense or hard doughs.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Drillstar PDC hole opener is a reliable solution for hole enlarging in both medium and hard formations. The body is machined out of a single block of heat treated AISI 4145H alloy steel. The three PDC arms are held in place by oversized locking pins. The unique design of the body ensures maximum strength and durability. It can withstand loads far beyond those involved during normal drilling operations. Cutting arms are fitted with two rows of PDC. During drilling, load is transferred directly from the arms to the body. No stress is sustained by the pins, substantially reducing the risk of losing parts downhole. Optimum cleaning is ensured by nozzles positioned below each cutting arm. Different sizes of arms can be adapted to the same body: for example the 9 1/2" OD body can be fitted with optional arms to enlarge up to 22" or 26". Special sizes of body and arms are available on request.

Request for a quote

HAKO GMBH

Germany

Hako offers a comprehensive range of singledisc and polishing machines that ensure brilliant results on hard floors. Machines of different size and performance classes are available to provide fast and efficient cleaning of all types of hard floors, supplemented by a wide range of floor care products and accessories.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

Combining the bestThe ZHU250CL hardness tester employs the latest technology, with closed-loop control for test load application. The modern system for test load application (closed loop) stands out because of its precision. Accuracy exceeds the requirements of all relevant ISO and ASTM standards. Range of Hardness Applications: - Vickers according to ISO 6507, ASTM E384 - Knoop according to ISO 4545, ASTM E384 - Rockwell according to ISO 6508, ASTM E18 - Brinell according to IS0 6506, ASTM E10 Features: • Extremely wide test force range of 0.5 kg to 250 kg • Unique “4-plus-4” turret able to carry up to 4 lenses and up to 4 indenters simultaneously. The turret is also designed to allow testing in hard to reach positions by using a unique vertical rotation mechanism. • Variable dwell times 5-60 seconds • Ability to vary indenter approach velocity • Rockwell depth measured by the market leading Indentec transducer capable of a measuring resolution of 0.1 Rockwell point

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZHU/Z2.5 is the most versatile and flexible hardness testing machine in the world, it has a zwickiLine testing machine with a hardness measurement head which contains a digital travel-measuring system and an exchangeable indenter with sensor foot. It can be used with all ZwickRoell Materials testing machines and in automated applications. All indentation depth measurement method hardness tests, including Martens hardness HM, Rockwell hardness, and ball indentation hardness can be performed. Vickers depth measurement HVT, Brinell depth measurement HBT, and Knoop tests can be performed with an optical unit accessory attached to the head. This unit contains a measuring microscope and a linear displacement component, which allows the microscope and load unit to exchange positions without the need to move any components under test.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZwickRoell 3105 Combi Test machine is a hardness tester that is controlled by a microcomputer. This unit is characterized by a highly accurate measurements in several IRHD and shore measurement ranges. This device eradicates the operator related errors due to having a fully automatic and digital measurement system across all Shore and IRHD ranges. This unit is also compatible with services that are concerned with sheet materials like performing an automatic test sequence. It has an indenter that scans the surface of the item before the spring generated load is applied.

Request for a quote

TOTALENERGIES LUBRIFIANTS

France

For forming and machining operations on hard steels and aluminium alloys.MARTOL SOLUBLE ST has been homologated by RENAULT S.A., as a forming oil under its experimental number of PX 3390.

Request for a quote

CASEARTECNICA BARTOLI SRL

Italy

The ROCK 20 model is a semi-automatic portioning machine for cutting hard and semi-hard cheese. Allows you to cut cheese into custom sized slices. Working times: about 15 / h wheels of Parmigiano Reggiano type cheese. Being a semi-automatic model, the machine requires a minimum commitment on the part of the personnel: it is sufficient to press two buttons to operate the blade and start the cutting action. The Rock 20 model allows you to customize both the size of the wedges (eg 700 g, 1-2-4 kg ...), and the type of cut to be made with the following accessories on request: Smooth blade: suitable for cutting hard and semi-hard cheeses; Heart extractor cylinder: tool that allows you to extract the central part of the shape (called the “heart” and sold separately), obtaining particularly small portions (eg 200-300-400 g…). The extraction of the "heart" prevents the creation of slices with too thin tips, which risk breaking or crumbling.

Request for a quoteResults for

Hard machining - Import exportNumber of results

34 ProductsCountries

Category

- Machine tools, metal machining - parts and accessories (8)

- Tools & Hardware (3)

- Grinding - machine tools (2)

- Knitting machines and accessories - industrial (2)

- Milling - machine tools (2)

- Street-cleaning machines (2)

- Testing equipment (2)

- Biscuit making (1)

- Blades for saws and cutting machines (1)

- Cutting - steels and metals (1)

- Diamond tools (1)

- Drilling - machine tools (1)

- Lubricants, industrial (1)

- Machine tools - metal machining (1)

- Milking - machinery and equipment (1)

- Milling - steels and metals (1)

- Precision engineering - portable power tools (1)

- Rolling machines (1)

- SMALL METAL PARTS (1)

- Testing of products and materials (1)