- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hard chromium plating

Results for

Hard chromium plating - Import export

SFS GROUP GERMANY GMBH

Germany

Working range Blind rivets up to 4 mm Ø all materials. Not suitable for stainless steel CAP® blind rivets. Technical data Weight: 1.2 kg Operating air pressure: 6 bar Air hose connection: 6 mm Ø (1/4’’) Air consumption: 0.8-1.2 ltr. per rivet (0,2 ltr. compr. air) Traction power: 5.200 N at 5 bar Stroke: 15 mm Nosepieces/accessories Nosepieces: 16/18, 16/24, 16/27 and 16/29 1 set of jaws, 1 spent mandrel bottle, 1 wrench each of MSU and MSZ, Maintenance instructions with spare parts list Features • Hydraulic head in aluminium with wear-proof cylinder surface • Pneumatic cylinder made of die cast aluminium • The piston made of hardened and hard chromium plated steel make the device easy to handle and wear-proof • Compact seals are wear-proof for a long service life • Fast venting valve for fast return and high working sequence • Low-noise pneumatic switching • Simple, low-interruption valve design • Hydraulic head can be adjusted by 360°

Request for a quote

DOREY

France

You can work many formats with or without contact with high quality and suitable for lamination of contact and contactless plastic cards BENEFITS Heating and cooling presses are independent, so the costly heating up and cooling down of the hot platens during each production cycle is totally avoided. The main frame of the heating and cooling presses are constructed of rigid welded steel. The main hydraulic cylinders are hardened, ground and hard chromium plated. The platens are guided by frictionless material. Heating and cooling presses are operated by a separate hydraulic system. A low pressure pump is used to lift the platen at a quick speed, while a high pressure pump is used to keep the heating and cooling presses at a high pressure. The pressure settings at the different stages of heating and cooling are programmable. The closed loop transport system significantly reduces material cassette loading and transfer time, resulting in much reduced consumption of energy.

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

Engineering-processes in aviation are among the most challenging we handle. Complex components for extreme applications and increasing requirements for material and energy efficiency shape development and manufacturing. Manufacturing precision components demands perfection in each individual production step. We support the entire production process with systems for all chemical and electroplating processes (including degreasing, etching, staining, hard chromium plating, nickel coating) and selected testing processes – from design to installation and maintenance. Almost all of our orders involve implementing complex and highly individual customer requirements. This results in custom-tailored, specialized solutions reflecting not only our experience and high commitment to quality, but also our profound flexibility.

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Induction hardened piston rods • Steels hardened up to 62 HRC • Hard chromium plated materials • Manganiferrous alloyed steels

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM 1230 Concrete Pavers and Block Making Machine; It is a machine that works fully automatic. The movement of the machine is programmed the PLC microprocessor computer. By changing moulds all kinds of pavers stone , curbs, block and precast concrete elements such as grass pavers series can be produced in a serial way. 20cm block can be produced 12 units in one press with the machine,or 30 interlock stones can be produced in a press. Machine is able to produce the insulated block upon demand. Our company’s special production vibrator is used. Thus, it can produce smoothly and quickly. Pneumatic bellows cylinders are used in connection of the mold of the machine. In this way a more uniform vibration propagation in the mold is obtained. Other than the mold and the press, thin and the bold mortar sections are moved over the hard chromium-plated column mills as well.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

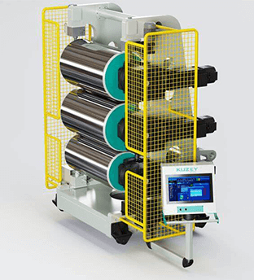

KUZEY GLOBAL

Turkey

The quality of a clear sheet is defined by the calender unit . For this reason, particular attention must be paid to the chromium plated and high-mirror polished solid calender rolls. These represent the quality for producing sheets with perfect surfaces. . The calender is a series of hard pressure rollers used to finish or smooth a sheet of plastic materials. These rollers are designed on vertical direction for PP, PS, PET however, for PET sheet only, rolls design as horizontal direction to reach high thicknesses while keeping homogeneity. Kuzey calender units provide high precision concentricity and flexural strength, even the thinnest of sheets can be manufactured with extreme accuracy. Each Roll is controlled with a separate thermo-regulators. Thermo-regulators can be adjusted separately from 10 – 90° C. Calender Thickness Motion control is by the servo and gearbox system.

Request for a quoteResults for

Hard chromium plating - Import exportNumber of results

8 ProductsCountries

Company type