- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding plants

Results for

Grinding plants - Import export

ROBINSON CO.

Turkey

Pellet sieves, take the oath pelletized powder pellet press again sends to the upper reservoir. pellet separated from the dust, Sent to the finished product silos. Depending on the space 2 or 3 cassette and 2 or 3 It is produced as output. Manufacturing is done in two separate models; vibrating screen and rotary screen. the centrifugal force will occur due to vibration and shaking vibration body vibration minimizing the special chassis system for dust separation, characterized in pellet diameter kullanılmaktadır.h. Dust sealing özelliği.kolay be changed 2 or 3 There ply sieve tray system. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

ROBINSON CO.

Turkey

The pellet crusher is a crusher specially designed to break 03-5mm granules into small pieces. With this design, the quality of pellet feed and pellet feed is improved. It is mainly used for poultry and fattening pellets and aquaculture pellets. The pellet crusher has two rollers, the working distance of which can be adjusted (manually or by motor). Thanks to the specially designed abilene rollers, all kinds of grains are processed with high capacity and quality. These rollers can always be used correctly to ensure high efficiency. The roller mechanism is fed regularly by the power supply unit. The pellet is evenly distributed over the entire surface of the roller. Thanks to a regular feeding with this mechanism, a homogeneous structured feeding with a low power and a lower dust content is obtained without overloading the machine. Application Fields ◾ Mixed Feed Plants ◾ Pellet Feed Plants ◾ Grinding Units

Request for a quote

KASAG SWISS AG

Switzerland

We have many years of experience in grinding and brushing of stainless steel surfaces for all object forms, as well as in the manual and machine grinding of circular objects. Our combined grinding machine/plant can be universally used, owing to its modular construction; it is of premium quality and guarantees surface roughness for stainless steel surfaces, on the inside and the outside for cylinders, spherical heads and cones for grinding welding seams superelevations for grinding longitudinal and circular welding seams roots

Request for a quote

VEHGRO B.V

Germany

"Origin Lemon grass, also known as Sereh, is a tropical plant from Southeast Asia with a strong citrus flavour and fragrance. The herb is widely used in Indonesian, Thai, Surinamese and Vietnamese cuisine. This lemongrass powder comes from Egypt. Use ground lemongrass (Cymbopogon citratus) is widely used in soups and curries, but also tastes very good with poultry, beef and fish. It has a fresh-sour flavour that gives depth to spicy or sweet dishes. Drying and grinding the stems of the plant produces a soft green powder. Ground lemongrass is more concentrated and has a stronger flavour than fresh lemongrass, so be careful with the amount of powder and add it carefully to your dish. You can also make tea from lemongrass. In Curaçao, this tea has been enjoyed for decades. It also freshens your breath immensely!"

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Extraction, crushing and grinding plants and their consumables: mills, hoppers, gutters, screens, trellises, conveyor belts, drums, rollers, fences, geared motors, buildings, supports, crushers, passageways, ladders, guardrails…

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

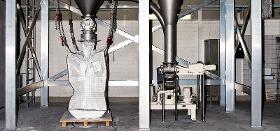

Dry micronization The optimal solution for fine grinding of bulk material We offer you a wide range of different types of plants for contract grinding in our fine grinding centers. Among them are special grinding plants, such as a special mill for natural products, an efficient circulating gas plant and a cryogenic grinding system for temperature-sensitive products. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Grain size exactly as you request it! Our fine grinding plants enable the dissolution of agglomerates as well as the breaking up of solid grain structures up to the finest grinding in a reproducible product quality. Customers of Ebbecke Verfahrenstechnik AG appreciate the flexibility of the available grinding systems that can be customized to suit the specific requirements of the grinding process. Nothing is left to chance because cutti

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Drug Mill The economic solution for grinding your natural products The drug mill used by us enables an economical external grinding of leaf drugs, herbs and plant roots for our customers. This way our clients save having to invest in their own, only mills that would only be fully utilized seasonally – at the same time they remain flexible with the production of teas, remedies or natural cosmetics. Technical data Throughput: 0,5-3 to/h Target fineness: 1-15 mm Product-contacting parts: Stainless steel Cleanability: Completely cleanable Grinding plant: Granulator with screen insert Feeding: Via bunker with clearing device and double shaft screw Container: Feeding as bagged goods, bales, Big Bags, octabins or in drums Areas of application Grinding of drug precursors Grinding of willow bark Grinding of St. John's wort Grinding of tea leaves Grinding of plant roots After grinding, filling in Big Bags or other containers Prospect for download

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Cryogenic Mill The solution for fine grinding temperature-sensitive products. Our cryogenic grinding plants enable fine grinding of lubricating and temperature-sensitive products. This not only results in a technically perfect grinding but in addition thermal damage of the ground material and resulting grinding losses are prevented by the cryogenic grinding. All plants are designed with swivel screw coolers and liquid nitrogen cooling, appropriate dosing devices, separators as well as bunkers as closed plants. Technical data Target fineness: 10-2,000 µm Plant types: Pin mills, cross beater mills Product-contacting parts: Stainless steel Cooling: By liquid nitrogen Delivery in: Bagged goods, Big Bags, oktabins, drums Feeding: Via feeding stations, metering screws and vertebral screw coolers Filling into: Bags, drums, Big Bags, cardboard boxes and special containers Areas of application Fine grinding of resins Fine grinding of foodstuffs Fine grinding of seeds Fine grindi

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Pastillation Molten products in granulate form As part of our contract pastillation we convert molten products into granulate. With our modern plants we produce granulate as pastilles, flakes or coarse discs according to the customers wishes. By continually transferring the molten output products across cooling belts in granulate form using cooling conveyors we realize an efficient conversion process. Depending on the product, industry and requirement, we work with various feeding systems, such as the efficient Rotoform procedure. This way additional plants for grinding or crushing are not necessary. This reduces energy consumption, protects the environment and reduces your costs. The granulates produced this way are dimensionally stable, have a homogeneous particle size range and are virtually dust-free. The products granulated at Ebbecke Verfahrenstechnik are also free-flowing and can be easily transported stored or further processed. Uncomplicated: Incoming goods and outgoing goo

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

POITTEMILL designs and realizes turnkey plants involving grinding, micronization, simultaneous grindingdrying and classifying for minerals of all kinds (limestone, clay, barite, talc, coal, plaster, quartz, bentonite.....). Depending the final application we are able to purpose you the most reliable equipment for your project.

Request for a quote

ASSFALG GMBH

Germany

The centrifugal plants are suitable for small parts. Due to the higher machining intensity with deburring, they deburr 10-20 times faster than vibratory finishing machines. The centrifugal plant can be planned as a single device up to a fully automatic plant. The grinding bodies and workpieces are accelerated through the rotational movement of the plate washer. Due to the centrifugal force, the workpieces are pressed outward and then transported up on the inner side of the system. Gravity causes these to fall back into the center of the plate washer to be accelerated again. A noise protection cover reduces the noise and makes it possible to work in a workshop. The speed regulation ensures versatile processing options. The programmable timer rounds off the autonomous work process. The machine can be expanded with an optional paper filter and separator.

Request for a quoteResults for

Grinding plants - Import exportNumber of results

13 ProductsCompany type