- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding of cutting tools

Results for

Grinding of cutting tools - Import export

WMC SINTERSTAR AG

Switzerland

Cutting discs from stock

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Metal-bonded grinding tools for flute grinding With the STARTEC XP-P+ product line, TYROLIT defines a new performance level for the flute grinding of tungsten carbide cutting tools. Two different diamond qualities and the innovative bond structure lead either to significantly reduced grinding forces or to a major increase in profile retention. The precision of the machined tools remains at the usual high level. Increased feed speed Easy profiling Extended dressing intervals

Request for a quote

COPIER MACHINERY

Netherlands

A heavy-duty CNC machine that creates perfect welding preps quickly with great precision in a short cycle. The Beaver CNC is the solid, sharp, and state of the art beveling machine series from Copier Machinery. The Beaver CNC Series has been developed over the years to get the best possible quality for the end-users. Our machine is the fastest, most accurate, and most durable solution for pipe beveling in the market. Copier offers a broad range of machining options within the portfolio of Beaver CNC, for pipes with an outside diameter of up to 56".

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

COPIER MACHINERY

Netherlands

Beaver CNC series is designed with the latest innovation and capable of finishing the pipe with both radial and axial feeding of the tool. Multiple applications like pipe beveling, facing, squaring, deburring, tapering, and threading can be performed on the inside and outside of a pipe without a need for a change of the tooling for different angles or shapes.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our files, bench stones, knife blade files and hollow chisel stones are available in different grit sizes from coarse to super fine depending on the desired application. Due to the large selection of different tools, the portfolio covers a wide variety of applications. The various files and stones can be used for machining tools in the woodworking and machine industries as well as for whetting knife blades. Tyrolit combination stones consist of two different grit sizes, allowing a wide variety of workpieces to be deburred. For improved ergonomics, certain products are equipped with handles to increase working comfort and make hard-to-reach places effortless to machine. One tool that no workshop should miss is the TYFIX hand rubbing brick, which allows you to effortlessly remove dirt, rust and paint from various surfaces. Tyrolit's tools are designed for different materials - from vitrified-bonded tools to resin- and electroplated diamond files for HSS and tungsten carbide.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Our experts continually innovate and optimize our range of abrasives, making Tyrolit a trusted partner in the automotive industry and other sectors requiring precise gear grinding. We offer a comprehensive assortment of grinding wheels, cup wheels, and worm grinding wheels for generating, bevel gear, and profile grinding. Generating gear grinding uses a worm grinding wheel to continuously grind the desired profile into the workpiece. Unlike this, profile gear grinding machines each gear tooth individually, suitable for large gears. Tyrolit's vitrified-bonded profile grinding wheels have set industry standards, delivering exceptional cost-efficiency, process stability, and finish quality for gears of all sizes. With increased quality requirements, hard-fine machining of gears is essential. Tyrolit's special cup wheel line for bevel gears ensures exact topographies and pitches, offering high productivity, low thermal load, and maximum profile retention.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit rondeller enhance its versatility, combining the benefits of various grinding tools in one product without needing special accessories like supporting discs or clamping nuts. Simply start working and enjoy the unique geometry and stud pattern of the rondeller, which offers excellent chip transport, cool grinding, and ergonomic use. The rondeller also guarantee vibration-free operation and optimal adaptation to the workpiece for grinding, deburring, and shaping curved surfaces. Tyrolit offers high-quality rondeller for metals, stone, and PVC. For steel and stainless steel, we recommend grit size 24/36 for high stock removal and grit size 60 for finer surface results. For deburring or grinding nonferrous metals like aluminum, copper, brass, or bronze, our rondeller contain a special bond to prevent clogging. Tyrolit also provides rondeller for professional machining of stone materials and PVC.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit's rough grinding wheels meet advanced economic requirements with high stock removal rates, ease of handling, and long life. Our innovative wheels ensure optimal results in both standard and special applications. In steel working, demands for better standing times, higher stock removal, and shorter machining are crucial. The CERABOND X range, with high-grade ceramic grain and innovative bond structure, meets these challenges, excelling on hard steel types and large diameters for economical processes and excellent results. Enhanced Safety and Comfort VIBSTAR reduces vibration by up to 50%, counteracting occupational diseases. SILENTIO reduces noise by 10 decibels, preventing physical damage and increasing comfort. "Comfort Start" technology ensures optimal performance from the start. High-Quality Grinding Wheels Tyrolit’s 1F80 range for straight grinders offers low-vibration work with high stock removal rates on steel, stainless steel, nonferrous metals, and cast iron.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit rollers are the result of continuous innovation aimed at improving this product segment. The high quality of our tools provides numerous advantages, especially for general grinding tasks like cleaning and finishing. Our rollers ensure consistently high-quality results on uneven surfaces throughout their lifetime. With a broad range of applications, they are ideal for removing welding marks, scratches, oxidation residues, and large-scale surface pretreatment. New to Tyrolit are spiral rollers with a patented shape that facilitates easy, comfortable work while preventing typical roller marks. Our rollers for floorstand grinders are perfect for finishing, polishing, and cleaning uneven or curved surfaces made of steel, stainless steel, and nonferrous metals. Available in various grit sizes, they cater to different needs: 40-60 for high stock removal, 80-120 for medium grinding, and 150-320 for a perfect surface finish.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In high-pressure grinding, the quality of the grinding wheel is crucial for the process result. It determines whether economical snagging of steel can meet technological requirements. Tyrolit's high-performance grinding wheels are designed to quickly and precisely achieve the required quality for further processing, supporting the production process. Snagging is the most common process for plastering semi-finished products. Our tools ensure high process quality, targeted and controllable stock removal, high production output, and consistent surface quality. They also guarantee high economic efficiency, easy handling, and low fault susceptibility. The SECUR line abrasives demonstrate the capabilities of our product range in high-pressure grinding. Many steel grades have surface defects, scales, and decarburization zones after continuous casting, which must be efficiently fettled before rolling mill processing.

Request for a quoteWMC SINTERSTAR AG

Switzerland

For cleaning and dressing grinding wheels

Request for a quote

WMC SINTERSTAR AG

Switzerland

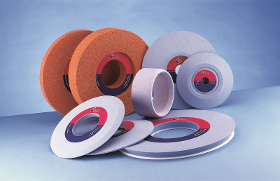

We represent the Sebald company in Switzerland. This company manufactures ceramic grinding wheels in its own production in Germany and has an excellent track record. With this we want to offer our customers an improved service. We look forward to conducting appropriate trials with you.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

The Tyrolit diamond cup wheel assortment offers grinding cup wheels for angle grinders in diameters from 100 to 180 mm, ideal for finishing and leveling unevenness on concrete, screed, and other mineral surfaces. They are also popular for bevelling edges on various substrates. Operators can choose from various designs, including cup wheels with high stock removal rates, special cup wheels for even results ideal for bevelling granite slabs, and cup wheels for hard-to-reach places, which are also excellent for floor grinding. Our PCD cup wheels are perfect for removing tough materials like adhesive residues, plastic or resin coatings, and sealants. Available with or without protection segments, they offer a smoother operation or more aggressive machining for stubborn coatings. Other benefits include a long lifetime, no clogging, and high grinding power due to the PCD segments.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

To achieve the required shape and dimensional accuracy, Tyrolit offers vitrified-bonded, resin-bonded, and electroplated CBN and diamond wheels. Our abrasives ensure safe working without thermal damage to the workpiece. This process is typically used for cylindrical or tapered workpieces, especially joints with an axis or shaft, such as gears, steering systems, injection systems, and hollow shafts. Tyrolit provides vitrified-bonded tools with excellent profile retention and cool finishes, reducing thermal load. Depending on the material, we recommend our superabrasives over conventional tools. Our resinoid bond, specially developed by Tyrolit, ensures shorter grinding times and maximum process stability. Resin-bonded diamond and CBN tools offer long tool lives and high dimensional accuracy. Electroplated tools exert low grinding pressure, ideal for small diameters.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Flap discs that excel in quality, performance, and handling are Tyrolit's standard. As a leading manufacturer of abrasives, Tyrolit offers a wide range of flap discs for various applications, including trimmable discs and those with natural fiber cores. Specifications vary for machining steel, stainless steel, or nonferrous metals, incorporating technologies like CERABOND, LONGLIFE, and FASTCUT. Each flap disc in our assortment is designed for specific uses. CERABOND discs, available with fiberglass or trimmable plastic backing, offer up to 30% more material removal and 100% utilization. FASTCUT discs are ideal for edge grinding and weld seam removal, providing maximum stock removal on various steels. Flap discs for nonferrous metals feature ceramic grain for self-cleaning and sharpening, preventing smearing and dullness. The C-TRIM with LONGLIFE technology ensures an above-average lifespan and full abrasive cloth utilization.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit centerless grinding wheels can grind workpieces from a few millimeters to several meters in length with maximum precision and cost-effectiveness, ideal for large series of identical parts. Centerless grinding wheels are notably thick compared to their diameter. Special pressing processes, adapted specifications, and sometimes split grinding wheels ensure homogeneous density distribution. Tyrolit offers a complete assortment of grinding wheels, regulating wheels, and dressing tools. Continuous product development guarantees high stock removal, tight tolerances, and fine surface results. Resin-bonded CBN grinding tools with a fiber-reinforced composite carrier body offer up to 80 percent less weight and better absorption properties, enhancing grinding results and tool life. Vitrified-bonded wheels use innovative sintering technology to prevent abrasive grain breakage. Lightweight diamond wheels are available for centerless through-feed grinding, gentle on machine spindles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

External cylindrical grinding is essential for achieving optimum surface finishes on workpieces like camshafts, crankshafts, and transmission shafts. It's used on various materials, including unalloyed, low-alloyed, and high-alloyed steels, HSS, tungsten carbide, industrial ceramics, and cast metals. The key to selecting the right tool lies in matching the grinding wheel to the specific requirements of the grinding application. This involves considering workpiece properties, tool, machine, settings, cooling lubricant, and dressing technology. Our high-quality tools and consulting services ensure optimal process parameters. Tyrolit offers a wide range of high-quality grinding tools for various applications and materials. We provide vitrified-bonded conventional wheels with different grains for specific materials, and resin-bonded high-performance tools made of CBN or diamond with our special bond system. The VIB STAR system reduces vibration for a smooth grinding process.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In precision manufacturing, demands on surface quality and component accuracy are continuously rising. Tyrolit's first-class abrasives ensure precision and functionality in products across all industries, such as watchmaking, eyewear or medical technology. Tyrolit's product portfolio guarantees high-quality machining of components with extremely narrow tolerances, whether for individual pieces or mass production. Our tools meet the most demanding dimensional tolerances. In the electronics industry, we supply cool-grinding diamond ring wheels with special bonds for wafer machining and long-lasting electroplated diamond grinding points for electronic components. The watch and eyewear industries rely on our elastic bonded grinding and polishing tools for precision mechanics components, ideal for deburring, fine grinding and polishing. For medical products we offer vitrified and resin-bonded grinding tools for knee and hip joints and silicon carbide wheels for pointing hypodermic needles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit serves industries demanding precision and efficiency in double side face grinding. We offer tools that meet the highest standards for precision, performance, and efficiency. With years of experience and innovation, we guarantee the production of plane-parallel functional surfaces of the highest quality without thermal surface damage, even for large grinding allowances and high stock removal volumes. Our tools help achieve the tightest tolerances. Our resin-bonded grinding wheels enable efficient generation of functional surfaces with high evenness and quality. Both face sides can be machined simultaneously, or one side at a time using wheels, segments, rings, or cup wheels. These abrasives offer constant grinding properties, long service life, and a cool grinding finish. Tyrolit also offers diamond grinding tools for ceramic components. Tyrolit's double side face grinding tools combine precision with efficiency. Our experts can help optimize your processes.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit leads in grinding wheels for surface and creep feed grinding, especially in highly porous wheels. Our products' high porosity and low hardness ensure maximum cutting ability and removal rates, even on hard materials. This market leadership is due to the intelligent design of our grinding wheels, tailored to material and workpiece geometry for tight tolerances and perfect surface finish. Grain type, grit size, grade, bond, and structure are adjusted for maximum precision and efficiency. Tyrolit offers a broad range of highly efficient grinding wheels for surface and creep feed grinding, ideal for the turbine industry. Our highly porous, vitrified-bonded abrasives guarantee long tool life, cool grinding, and increased profile retention. Electroplated wheels, primarily used in the turbine industry, provide excellent profile accuracy and maximum process stability, resulting in precise grinding results and lower component costs.

Request for a quote

COMERC SP. Z O.O.

Poland

The CMB series hammer mills manufactured by our company are intended to crush and uniform fractions of dry bulk materials with moisture contents of up to 15% and destined for further technological processes. There is option to grind raw materials with higher moisture content, but this parameter has a very significant impact on the device performance. Depending on needs and purpose, CMB series hammer mills cay operate with capacity from 2 t/h to 10 t/h. The raw material is crushed by the impact of the hammers on the raw material and the raw material against the walls of the crushing chamber. The regularity and size of the resulting fraction is determined by the diameter of the holes in the screen used. We recommend collecting the crushed material from under the mill with pneumatic transport, as this enables the use of a pneumatic separator to sift out stones and other impurities that may cause explosions. The use of pneumatic transport will also increase the performance of the mill.

Request for a quote

CAJHEN, D.O.O.

Slovenia

High-quality custom cutting tools are adapted to individual projects, with which we achieve high efficiency and improve the competitive advantage of our customers. They represent 94 % of our production.

Request for a quote

CAJHEN, D.O.O.

Slovenia

The materials from which we make cutting tools are key to your success in use. They provide exceptional performance and long-lasting value, especially those made from super hard materials that have exceptional abrasion resistance. We manufacture cutting tools from various grades of carbide hardness, PKD, CBN, and MCD.

Request for a quote

CAJHEN, D.O.O.

Slovenia

We sharpen cutting tools on 5-axis CNC machines, restoring the efficiency of used tools to that of a new tool. We are sharpening tools of all brands and shapes.

Request for a quote

POLIBRAS S.A.

Portugal

For Portable Machines Diameters: 115mm to 230mm

Request for a quote

ASSFALG GMBH

Germany

The handy drill grinders are ideal for grinding HSS- and VHM spiral drills. HSS drills are ground with CBN grinding discs and VHM drills with diamond grinding discs. Through the adjustable point angle from 90-140° and the adjustable point thinning equipment, these models can be used universally for different drill types. Easy handling and their efficiency make this machine a real winner in the field of drill grinding. Approx. 0.3mm is removed during each grinding process. The double-bearing grinding equipment guarantees a precise finish. The EDG 213 covers a drill diameter range from 2-13mm and the EDG 1226 from 12-26mm. Advantages: Precise regrinding of HSS and VHM spiral drills Easy operation Compact construction Fast and easy grinding disc change Point angle adjustable from 90-140° Adjustable point angle mechanism Comprehensive delivery accessories

Request for a quoteResults for

Grinding of cutting tools - Import exportNumber of results

105 ProductsCountries

Company type

Category

- Cutting - machine tools (72)

- Grinding - machine tools (23)

- Industrial cutting machine tools (6)

- Thread-cutting - machine tools (5)

- Machine tools, cutting - parts and accessories (4)

- Abrasives, mechanical (1)

- Blades for saws and cutting machines (1)

- Diamond tools (1)

- Do-it-yourself hand-held power tools (1)

- Drilling - machine tools (1)

- Sharpening - steels and metals (1)