- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grinding materials

Results for

Grinding materials - Import export

PJSC ZAPORIZHZHIA ABRASIVE PLANT

Ukraine

The BSC grinding materials are widely used in the abrasive tools manufacturing and fixed-abrasives - rougher, cutting-off and grinding; tools on a flexible base - coated abrasives, in the process of loose abrasive grains grinding. The BSC grinding materials are used: in the process of iron and nonferrous metals, carbon, glass and ceramics, stone, concrete, bricks and chamotte, wood substance, plastics, leather, rubber, and other hard, tough, brittle, alloys, and materials of natural and artificial origin treatment; in the refractory and ceramic industries as a component for moldings and antipenetration washes, in the process of crucibles for casting of non-ferrous and precious metals production, for wash troughs. Refractory products of silicon carbide abrasive materials have high thermal conductivity, heat resistance (deformation starting above 1500 C), resistance to acid slags.

Request for a quote

PARSMEGA MAKINA

Turkey

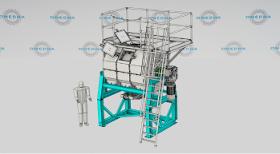

IT IS A MACHINE THAT ENABLES BREAKING GRAINED PRODUCTS TO THE DESIRED SIZE. FEATURES: TWO-DIRECTIONAL FEATURE. DYNAMIC AND CYTATIC BALANCED STRONG ROTOR POSSIBILITY TO GRIND RAW MATERIALS WITH 0.2-0.8 kg / dm3 DENSITY ELECTROPNUMATIC DEFLECTOR QUIET OPERATION 90-93 dB EASILY CHANGEABLE HAMMER AND SIEVE SYSTEM COVER WHEN MOTOR CURRENT IS GIVEN SECURITY SYSTEM THAT LOCKS LARGES, TWO-WAY WORKING POSSIBILITY, POWERFUL AND LONG LIFE BEARING BEARING SYSTEM HEAT TREATMENT HARDENED HAMMER AND HAMMER BAR SHAFT

Request for a quote

ROBINSON CO.

Turkey

The control sieve is used for the final control before packaging in the packaging unit of the flour factories. The product arriving at each passage of the square screen enters through the pressure pipe and moves vertically and horizontally through the pre-set flow paths along the passage. The final checks are made after the flour sifting process. The flour, whose last checks are made, is directed to the bagging process. Apart from flour and semolina factories, it is used in processing plants of wheat, corn and similar grains, in feed mills, in various food products processing plants for the final screening of mixed feeds and for the sifting of large-grain corn, crushed pellet feed, barley, oats and similar processes. Application Fields ◾ At flour mills: For wheat, corn and similar grain processing plants ◾ At feed mills: For final sifting of formulated feed meals, corn, crushed pellet feed, barley, oats and for removing the remained coarse materials after grinding and similar processe

Request for a quote

ROBINSON CO.

Turkey

This hammer mill grinds easily raw materials which are dry and lle dampens fine. For this reason it is used in food industry.The body is of steel and weld construction. The hammers are on the rotor which turn a mill. The rotormill turns in the strong ball thrust. The hammers are made of hardened steel.It is designed turn free.The sieve is on the hammer mill and it is changed easily without stopping the rotor. Motor is connected directly to the coupling. The body of hammer mill is mounted on the same chassis. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit leads in grinding wheels for surface and creep feed grinding, especially in highly porous wheels. Our products' high porosity and low hardness ensure maximum cutting ability and removal rates, even on hard materials. This market leadership is due to the intelligent design of our grinding wheels, tailored to material and workpiece geometry for tight tolerances and perfect surface finish. Grain type, grit size, grade, bond, and structure are adjusted for maximum precision and efficiency. Tyrolit offers a broad range of highly efficient grinding wheels for surface and creep feed grinding, ideal for the turbine industry. Our highly porous, vitrified-bonded abrasives guarantee long tool life, cool grinding, and increased profile retention. Electroplated wheels, primarily used in the turbine industry, provide excellent profile accuracy and maximum process stability, resulting in precise grinding results and lower component costs.

Request for a quote

STEINSTOSSER & SCHMACHTENBERG GMBH & CO. KG

Germany

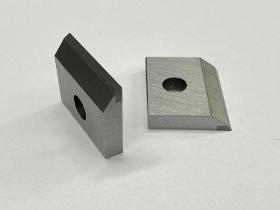

Different tungsten carbide qualities with a hardness above those of the standard and PM special qualities. Through clean grinding materials, we achieve a long working life through high resistance to wear.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit divides the floor grinding process into three parts: rough grinding, pre-polishing, and polishing. In the first two steps, material is removed, and in the third phase, the floor gets its final finish. After each stage, chemical agents are used to densify, seal, or finish the floor. Customers receive these chemicals directly from Tyrolit. In rough grinding, material is removed based on the desired final appearance. Tyrolit offers metal bond grinding shoes with different grains. Cracks and pores are repaired with a special chemical filler. In pre-polishing, the floor is ground with ceramic/resin bonded tools to level it. A densifier compacts and hardens the surface, reducing water absorption. In the final polishing phase, the floor is sealed with a "sealer" to protect against liquids, grease, and dirt. Tyrolit's floor grinding chemicals transform drab substrates into robust, resilient floors with a long-lasting and appealing appearance.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The deburring discs of the FAPI-125 series are the ideal tool for deburring on automatic, stationary deburring machines and are particularly suitable for processing larger series. The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. We will be pleased to advise you which fill variant is best suited for your application. Product features Ultra-fast setup times The shank allows easy mounting and positioning of the deburring discs FAPI-125 on the deburring machine. The selection of different densities, fill lengths, abrasive cloth and abrasive fleece types can have a decisive influence on the deburring process. The optimum design of the deburring discs FAPI-125 can be determined from the process parameters dry or wet grinding, the material to be processed, the material thickness and the desired surface quality or roughness depth. We will be happy to advise you in order to find a suitable deburring disk for you.

Request for a quote

KAUFMANN GROUP

Slovakia

Our experts are dedicated to thorough material preparation prior to welding, including grinding, cleaning, and even material fitting. Their meticulous work ensures that the material is optimally prepared for welding, thereby enhancing the final quality.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia Ball Mill /Beads / Grinding Media is made of good material and used advanced technology, which is suitable for any kinds of mills such as sand mill, attrition-mill, vibratory mill, ball mill and so on. It is used to grind and disperse the material of painting, dye,ink, titanium, electronic battery material, rare-earth material, nonmetal ore, calcium, pesticide, food stuff and medicine etc..Because of its high density, toughness and hardness, zirconium grinding media’s efficiency is much better than traditional ones.The high wear-resistant zirconium grinding media can not only prevent materials from being contaminated, but also prevent chemical erosion that affects its working life Sizes Ømm of the Zirconia ball mill grinding media : - 0.2-3mm,5mm,10mm,15mm,20mm Usage of the Zirconia ball mill grinding media: - Ø0.5-3mm Grinding ball use in sand mill - Ø5-20mm Grinding ball use in mix mill and ball mill - OverØ20mm Grinding ball use in ball mill

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Alumina ceramic jars are used whenever small quantity of samples needed to be grinded. Each jar set includes grinding jar, lid, rubber sealing gasket and different sizes of mixed alumina ceramic grinding balls. It is best container for grinding rare earth materials, precious metals, medium and low ceramic capacitors, NTC, PTC piezoelectric ceramic and lithium We can customize various types of vacuum jar according to customer's needs. Physical Parameters: Composition: Al2O3 ≥ 99% Specific Gravity: ≥3.8 g/cm³ Hardness: 9 Mho’s Bending Strength : > 350 Mpa Water Absorption Rate: ≤0.005%

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd is specialize in custom machine parts more than 20 years, we have various automatic lathe turning machines can produce small turned parts, especially produce steel pins with low cost and high speed. We have can do further machining and treatments for steel pins, such as milling, grinding, drilling & hardening treatments. Common materials for pins are 35 or 45 steel. The material of the safety pin is 35, 45, 50, T8A, T10A, etc., and the hardness after heat treatment is 30~36HRC. The pin sleeve material can be 45, 35SiMn, 40Cr, etc., and the hardness after heat treatment is 40~50HRC. Pins play a pivotal role in the connection of mechanical components. According to different shapes and functions, it can be divided into: split pin, tapered pin, cylindrical pin, grooved pin, dowel pins,coupling pins, etc. Among the pin products, cylindrical pins, tapered pins and split pins are commodity fasteners that are produced.

Request for a quote

COMERC SP. Z O.O.

Poland

The CMB series hammer mills manufactured by our company are intended to crush and uniform fractions of dry bulk materials with moisture contents of up to 15% and destined for further technological processes. There is option to grind raw materials with higher moisture content, but this parameter has a very significant impact on the device performance. Depending on needs and purpose, CMB series hammer mills cay operate with capacity from 2 t/h to 10 t/h. The raw material is crushed by the impact of the hammers on the raw material and the raw material against the walls of the crushing chamber. The regularity and size of the resulting fraction is determined by the diameter of the holes in the screen used. We recommend collecting the crushed material from under the mill with pneumatic transport, as this enables the use of a pneumatic separator to sift out stones and other impurities that may cause explosions. The use of pneumatic transport will also increase the performance of the mill.

Request for a quote

FOODCOM S.A.

Poland

Native Corn Starch is produced by cleaning and grinding raw corn material and separating the gluten and starch. The resulting starch slurry is then dried and processed into a fine white powder with a neutral taste and odor. This non-GMO product can be chemically or physically modified or left unmodified. It has a shelf life of 24 months and should be stored in a dry environment below 25°C and away from odorous materials. Foodcom S.A. supplies Native Corn Starch to its Business Partners in 25 kg bags, Big Bags and in bulk. Native Corn Starch is widely used in food production, including candy, confectionery, and prepared foods. It is also used in other industries such as paper, textiles and adhesives, as well as for medical purposes and in animal feed.

Request for a quote

LASVA LIIMPUIDU AS

Estonia

We offer various material processing services: Grinding / calibration for thickness (maximum width 1200mm) CNC processing (according to the program and drawings) Drilling and doweling (according to the program and drawings) Processing of edges in a go-through bench (double tenon) (according to existing profiles) Planing Finishing service for wooden surfaces (hand spray, coating on UV-rollerline)

Request for a quote

REA ELEKTRONIK GMBH

Germany

The latest generation of REA JET GK 2.0 high-resolution coding and marking systems using piezo technology is suitable for direct, high-contrast coding and marking on absorbent and porous surfaces, such as wood, cardboard and paper, with a variable print height of up to 100 mm. Applications: — Porous and absorbent surfaces: paper, cardboard boxes, wood, textiles, fleeces, building materials, polystyrene, grinding wheels etc. — Variable print data such as date, time, counter, shift code or database content — Alphanumeric texts, barcodes, data matrix codes, logos, warning notes — Coding and marking of packaging — IPPC coding and marking on pallet blocks — EPAL coding and marking of pallets — CE marking on wood — Marking of paper sacks — All-round coding and marking of fiber drums — Marking of OSB panels with logo — Coding and marking of pallet boxes — Marking of gypsum boards or board stacks with large logos — Serialization and track & trace applications

Request for a quote

OMECHA UAB

Lithuania

Ball mills for crushing, and separating bulk materials. Batch milling controls the size of the material by adjusting the grinding time. The ball mill uses steel balls as grinding media. The ball mill can efficiently grind various materials into fine particles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OGGO TECH MAKINA TEKNOLOJILERI SAN. TIC. LTD. ŞTI.

Turkey

We are experts in gear production and gearbox manufacturing in Turkey, as one of the highest quality and competitive gear manufacturing company in Turkey we can provide gears, gearboxes, transmission of spur gears, helical gears, herringbone gears, shafts, transmission gears, gearboxes, pto gears, bevel gears, heat treated gears, grinded gear production, cementation gear production, cast gear manufacturing, welded gears. Contact us for gear production in Turkey.

Request for a quote

OGGO TECH MAKINA TEKNOLOJILERI SAN. TIC. LTD. ŞTI.

Turkey

We are experts in gear production and gearbox manufacturing in Turkey, as one of the highest quality and competitive gear manufacturing company in Turkey we can provide gears, gearboxes, transmission of spur gears, helical gears, herringbone gears, shafts, transmission gears, gearboxes, pto gears, bevel gears, heat treated gears, grinded gear production, cementation gear production, cast gear manufacturing, welded gears. Contact us for gear production in Turkey.

Request for a quote

OGGO TECH MAKINA TEKNOLOJILERI SAN. TIC. LTD. ŞTI.

Turkey

We are experts in gear production and gearbox manufacturing in Turkey, as one of the highest quality and competitive gear manufacturing company in Turkey we can provide gears, gearboxes, transmission of spur gears, helical gears, herringbone gears, shafts, transmission gears, gearboxes, pto gears, bevel gears, heat treated gears, grinded gear production, cementation gear production, cast gear manufacturing, welded gears. Contact us for gear production in Turkey.

Request for a quote

YONGMING MACHINERY MANUFACTURING CO., LTD

China

SFSP Series Hammer Mill is mainly used for crushing granular materials such as corn, cereals, chaff, sunflower skin, etc.The machine has the characteristics of high output, stable work, safety and reliability, convenient loading and unloading, and easy operation. And it has strong adaptability to materials, and is currently the ideal high-efficiency crushing equipment, which is widely used in processing industries such as grain, feed, oil, food and chemical industry. The grinder applies direct-connect drive. The raw materials in the grinding room are broken into peaces by hammerhead striking and cutting. In addition, the attrition-of among materials and between material and sieve plate makes materials smashed more. Finely ground particles will pass through the sieve but the residues further are ground until them change enough to pass the sieve mesh. So, all the materials will be ground completely.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

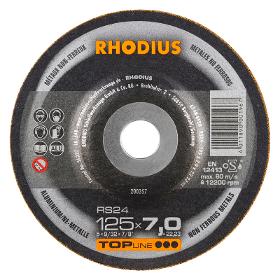

Grinding disc with special filler materials prevents clogging while ensuring efficient and continuous grinding. • High stock removal performance • No clogging of the disc • Minimum material heating

RHODIUS ABRASIVES GMBH

Germany

Waterproof abrasive paper with silicon carbide on a paper backing. • Closed coated silicon carbide for high material abrasion • Fine grinding grit 2000 • Flexible paper underlay for optimal workpiece adaptation

YEK PRINTING

Turkey

When it comes to luxury box, the tassel box is the box models produced by grinding (dressing) coating materials such as coated paper, fancy paper, fabric, thermo leather, binding cloth on hard cardboards starting from 1 mm up to 4 mm. Compared to standard cardboard boxes, they are mostly produced by hand and are thicker, more durable and more useful. Each skin (coating) material has a specific glue density requirement and a waiting time (tempering). Therefore, although the first adhesion may seem easy to manufacture, it requires mastery, experience and care. Almost all of the low-volume boxes are produced by hand. If it is over a certain number, it is done in semi-automatic and fully automatic box grinding machines. Drafting box models and usage areas; - Jewellry, Furniture, Shoes, Clothes, Food and etc

Request for a quote

PJSC ZAPORIZHZHIA ABRASIVE PLANT

Ukraine

Boron Carbide (BC) is characterized by extra-hardness: it is the third substance after diamond and cubic boron nitride material, with high wear-resisting property, chemical resistance in aggressive environments, heat resistance, neutron absorption large cross-section, high electric resistance and semiconductor properties. The grinding materials are used for grinding and polishing by loose abrasive grains and in the form of pastes. BC is widely used in the nuclear industry for the control rods manufacturing. BC is used in the process of armor plates and bullet-proof body armor manufacturing.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Dry micronization The optimal solution for fine grinding of bulk material We offer you a wide range of different types of plants for contract grinding in our fine grinding centers. Among them are special grinding plants, such as a special mill for natural products, an efficient circulating gas plant and a cryogenic grinding system for temperature-sensitive products. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. Grain size exactly as you request it! Our fine grinding plants enable the dissolution of agglomerates as well as the breaking up of solid grain structures up to the finest grinding in a reproducible product quality. Customers of Ebbecke Verfahrenstechnik AG appreciate the flexibility of the available grinding systems that can be customized to suit the specific requirements of the grinding process. Nothing is left to chance because cutti

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The Double Stream Mill, series PSKM is used for the fine preparation of precut wood chips and annual plants such as bagasse, miscantus, cotton stalks, hemp stalks, corn straw and rice straw. The fine flakes produced are characterized by their low percentage of dust and coarse particles. The areas in which the end material is used are diverse. It is used for energy generation, as insulation material, the reinforcement of building components and as raw material for the production of fine surface layers of particle boards. Characteristics, Function Compact and sturdy, designed for continuous operation Bearing- and drive system easily exchangeable as a complete unit A slide to remove the grinding ring is supplied as standard. Dismantling of the impeller is not necessary Material feeding via vibratory feeder and a feed chute designed as a gravity separator Even distribution of the material in the grinding chamber Size reduction is performed by repeated impact onto the impeller...

Request for a quote

APEX TOOL GROUP GMBH

Germany

Quality, ergonomics and power are the core features of the new Cleco® Vertical Grinders. For grinding applications requiring maximum material removal, as e.g. heavy roughing work, the new powerful Cleco® Vertical Grinders with 2300W or 3100W motors are THE solution. Engineered for the most serious heavy-use industrial applications, the new Cleco® Vertical Grinders are built to deliver unmatched productivity, maximum material removal and long service life. - Powerful 2300W and 3100W motor engineered for maximum sustained power - Robust one-piece all metal housing and powerful long-life motors - Ultimate reliability and ruggedness - Reduced weight and height (175 / 208 mm; 4,4 - 5,4 kg) for improved ergonomics - Low maintance and longer user “up time” - Streamlined 1 piece all metal housing and handles are engineered for ultimate ruggedness and best ease of use - High versatiliy through 180°reversible throttle handle and interchangeable guards (150mm, 180mm, and 230mm)

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Plastic Mill The solution for the production of plastic powder Our fine grinding plants for plastic granulates enable the grinding of a wide variety of plastic granulates including even the finest grinding. All our grinding plants for bulk material processing are made of stainless steel and designed with dosing devices, discharge with one-way filters, separators and bunkers as closed plants. The ground goods can be processed on site or poured directly into the container specified by the customer. Technical data Target fineness: 200-1,000 µm Plant types: Disc mills, pin mills, granulators, cryogenic grinding plant Container: Bags, Big Bags, octabins, drums or drums Feeding from silo possible Filling from silo vehicles is possible Areas of application Fine grinding of LDPE Fine grinding of polypropylene Fine grinding of polystyrene Fine grinding of polyamide Fine grinding for simultaneous de-dusting of the finished product Fine grinding of EVA under cryogenic conditions

Request for a quoteResults for

Grinding materials - Import exportNumber of results

45 ProductsCountries

Category

- Grinding - machine tools (4)

- Ceramics, industrial (2)

- Crushing and grinding machinery (2)

- Flour milling - machinery and equipment (2)

- Gears (2)

- Industrial design (2)

- Pharmaceutical industry - machinery and equipment (2)

- Siliceous limestone bricks (2)

- Adjustment - machine tools (1)

- Bending machine tools (1)

- Boxes, cardboard (1)

- Ceramics - tiling (1)

- Condiments, extracts and spices (1)

- Diamond tools (1)

- Electric and electronic components - machines for manufacturing (1)

- Finishing work (1)

- Food canning and preserving - machinery and equipment (1)

- Forestry (1)

- Grinding - steels and metals (1)

- Injection moulding of rubber and plastic (1)