- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grain separator

Results for

Grain separator - Import export

PLANT OF AGRICULTURAL MACHINERY

Ukraine

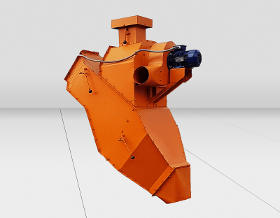

The AS-60 air separator is used when cleaning grain to separate dust and light fractions from the grain. It can be used for different types of cereals, for example, for wheat, durum wheat, corn, rye, soy, oats, buckwheat, millet, rape, rice, as well as for sunflower, peas, chickpeas, beans, cocoa beans, etc. Cleaning grain from dust and light impurities ensures its long-term storage and helps to prevent various potential threats. Due to the unique design of the cascade type, the AS-60 air separator provides high quality cleaning of grain from dust and light impurities. Air speed and grain feed are very easy to adjust with 3 handles. This allows you to adjust the separation settings at any time depending on the properties of the grain being cleaned. Due to its simple, effective design and wide adjustment range, the AS-60 air separator has many applications. This separator can be used separately, installed in stationary grain cleaning lines or used as part of mobile grain cleaner.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants.

Request for a quote

ROBINSON CO.

Turkey

It is used to separate heavy foreign materials such as stones, glass and metal pieces or soil pieces in the grain with the help of screening method and air. The machine consists of a fixed chassis and vibrating body. The stone separator, designed considering the difference in density of stone and grain, separates the stone by directing the grain in the direction of gravity, in the opposite direction of gravity, with the help of vibration. Wheat is separated from the stones with the help of a vibrating sieve. In addition, dust is absorbed by the air aspiration provided from the ventilation line. Apart from flour and semolina factories, it is also used in all grain factories, vegetable oil factories, cocoa and coffee processing plants. Application Fields ◾ At food industry ◾ Flour and semolina mills ◾ Cereal cleaning plants ◾ Corn factories ◾ Oil factories ◾ Malt factories ◾ Cacao and coffee plants

Request for a quote

ROBINSON CO.

Turkey

It performs the task of separating the light grains and shells of the unwanted foreign substances from the grain with the air flow. The grain is spread over the bottom by a vibrating feeder and conveyed towards the air duct. It is washed by the air flow opposite the movement of the grain, which enters the air channel with a homogeneous distribution. In the meantime, unwanted light grains are separated from the grain by moving with the air. Applications Fields ◾ Food Industry ◾ Flour Mills ◾ Semolina Mills ◾ Feed Mills ◾ Grain Cleaning Plants ◾ Corn Processing Plants ◾ Oil Factories ◾ Plywood Factories ◾ Grain Storage Silos ◾ Corn Mills ◾ Corn, barley, rye, oats, and so on grain processing plants

Request for a quote

PARSMEGA MAKINA

Turkey

Hulling machine is used to peel wheat. Separates foreign substances such as dust, sand and small seeds in wheat. It crumbles the soil and other adherent grains attached to the wheat grains, reduces the bacterial load, and cleans the wheat from bacteria and insects. It also enables the separation of grains that have not been separated from the spike. Thanks to this new model, a smaller design but higher capacity has been achieved compared to our old model. Instead of flat pallets in the previous model, cast pallets were used in this model and the product contact surface was increased. In this way, a more efficient peeling process is achieved.

Request for a quote

PARSMEGA MAKINA

Turkey

Hulling machine is used to peel wheat. Separates foreign substances such as dust, sand and small seeds in wheat. It crumbles the soil and other adherent grains attached to the wheat grains, reduces the bacterial load, protects the wheat from bacteria and insects. Ours. It also enables the separation of grains that have not been separated from the spike. Wheat entering the machine from the wheat inlet section directly enters the wheat peeling section. Here, the wheat is husked by the rotation of the steel rotor, and the clean, hulled wheat is directed to the outlet thanks to the pallets on the rotor. The husks and dust separated from the wheat are thrown out of the machine with air through the holes of the steel braided wire on the rotor.

Request for a quote

PARSMEGA MAKINA

Turkey

Garbage separator machine is used to separate foreign grain products such as garbage and straw in wheat. The garbage purifier consists of two parts. Upper sieve part: It separates the large foreign substances in the wheat and throws them out. Lower sieve part: It eliminates small foreign substances from the wheat that pass through the upper sieve part and fall on it. Both screen wires can be easily removed and installed by hand. Wheat entering the machine from the product entrance is distributed smoothly and homogeneously on the sieve thanks to the vibromotor mounted on the center of gravity of the machine. The feeding box is oscillated with the body working by vibration on rubber wedges. With an adjustable flap, it ensures that the wheat is distributed across the entire sieve surface.

Request for a quote

ROBINSON CO.

Turkey

It’s for selecting the materials adjusts or aches and non- needed, which are in the wheat. The rollers pushed on the It separates impurities such as seed, barley, rye, lentil, cracked wheat, long grain and absut in wheat, corn, lentil, rice, and similar grains and is used to separate the broken pieces. Foreign substances and broken grain in the product entering the rotating drum enter into specially made drum pockets with a rotating steel body by centrifugal force. When the rotating drum reaches a certain point, foreign substances and broken grains in the pockets fall into a special adjustable channel in the drum. While the cleaned grain comes out of the drum, foreign substances and broken grains falling into the channel are ejected by a spiral placed in the channel. During operation, the dry grain in the drum makes powder. This dust is extracted by low pressure air. In the food industry; In flour and semolina factories, Bulgur factories, In lentil cleaning facilities,

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating screens are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or as functional organs to feed belts or crushers. Depending on the task, the devices are designed with a robust inlet area with liners (wearing plates) followed by two or three bar grate levels. Each rod is made in a tapered shape which results in a widening gap and bulk jams are avoided. The areas to use such strainers are the primary industry, stones, earth, coal industry with grain sizes up to 1,000 mm in length, but also the chemical and food industry. Everywhere, where a roughly screening and separation of fine and gross material is needed. Advantages & benefits Wide range of applications: product to feed screening of gross grain separation of gross grain before classifying separation of fine grain from crushers protection screening in front of conveyor belts Construction The main components ar

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The grain separator is used to separate small and big foreign materials (paper, straws, corn, soil etc. ) from the grain. The product is evenly distributed on the sieves by the adjustment gate at the grain intake as well as the distribution devices on the sieves. The machine consists of a vibrating body installed on a stable chassis. It is driven by two symmetrical vibration motors. The vibration level of the machine is adjusted by changing the inclination level of these motors. Rubber vibration dampeners are used to isolate the vibration. There are two layers of sieves in the grain separator. While the first layer separates the particles bigger than the grain, the second layer separates smaller particles. The grain separator has to be used with an air-channel or radial air separator. This way, the light particles are removed as well.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

The trieur separates broken grains and other foreign materials from the wheat. The wheat enters the drum and the foreign materials and broken grains are collected into the pockets located on the drum. These foreign materials are discharged by the screw conveyor located inside the drum.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Inertia Vibratory Grate Feeders are a type of feeders in which grates are the element used to feed the material. Grate feeders are mainly used for materials with medium and large grain size, they are perfect as feeders for crushers and for stone processing. The grate in this type of feeders is made in a fixed (welded) or active (bar) version. In addition, depending on the customer’s needs and the intended use of the machine, the grates are made as flat or cascading. The material used for the production of the grate, depending on the needs, is structural steel, wear-resistant steel, or in the case of bar grates, spring steel. Thanks to their construction, Grate Feeders enable partial separation of oversize grain. Active grates made in a steel or polyurethane frame. In feeders of this type, thanks to the use of electric vibrators, high efficiency is achieved at relatively low power consumption.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

OBC-25CE is a stationary grain cleaning machine equipped with unloading elevator additionally. Presence of such kind of elevator simplifies grain cleaning process and makes it possible transferring grain into vehicles, grain vessels, trailers, big bag etc. Machine can also be equipped with a boot elevator and cyclone if necessary. On customer request wheels can be installed to OBC-25CE that turns the unit into mobile one. OBC-25CE performs grain and seeds cleaning using an aspiration system and sieves. Spreader separates impure grain in two equal parts and directs it to air channels. Fan airflow takes light impurities out. Larger impurities are captured with settling chamber from air stream. After that grain purified in aspiration system comes to upper and lower sieves. At these sieves grain gets cleared of impurities kind of different size. Pure grain is collected at the bottom of OBC-25CE and unloaded with built-in elevator.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

Stationary grain cleaner OBC-25S performs cleaning of cereals, legumes, sunflower, sorghum, rapeseed, corn, etc. Grain cleaner OBC-25S is installed in existing grain cleaning units or mounted separately. OBC-25S is equipped with a receiving chamber, an air-cleaning part, sieves, a feed waste screw. All working bodies are mounted on the frame. OBC-25S performs cleaning of grain and seeds using an aspiration system and sieves. The distributor divides the grain with impurities into two equal parts and directs it to the air channels. Airflow through the fan carries off light impurities. Larger impurities from the air stream are captured by the settling chamber. Further, the grain purified by the aspiration system falls on the upper and lower sieves. On sieves, the process of cleaning grain from impurities that differ from grain in size occurs. The sieves are cleaned with brushes. If necessary, OBC-25S can be additionally equipped with loading and unloading elevators, as well as a cyclone.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

3BC-20A grain cleaning machine performs the following functions: - eliminates dust and light trash using a powerful integrated suction system; - using 16 sieves installed in the machine, it carries out high-quality cleaning of grain heaps from large and small impurities, debris, chopped grain and separates the grain into fractions. 3BC-20A is a reliable and popular grain cleaning machine, which is successfully used for cleaning cereals, legumes, oilseeds, corn, sunflower, sorghum, rape, coriander and many other crops. With the help of 3BC-20A, even very contaminated grain can be effectively cleaned to produce a quality product. 3BC-20A is a universal grain cleaning machine that can operate in three modes: in pre-treatment of grain with a capacity of up to 50 tons per hour; in primary grain cleaning mode with a capacity of up to 25 tons per hour; in the calibration mode of grain for seeds with a productivity of up to 12,5 tons per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The universal seed separator with cyclone OBC-355C is the most multifunctional drum separator for cleaning any grain and seeds. The number of applications for this separator exceeds 50. This is achieved through an innovative block design with a large number of reversible valves and an additional auger at the bottom of the cleaning unit. The main parts of the OBC-355C are the OBC-355 seed separator and the aspiration system, to the outlet of which a cyclone with 3 supports is connected through an air duct. Grain separators OBC-355C have the following main advantages: Maximum versatility in application. Greater cleaning efficiency. High accuracy of grain calibration by aerodynamic properties, width and thickness. Minimal vibration during operation. Fast replacement of sieves. Gentle handling of seeds and grain. Adjustable performance. The presence of a cyclone that traps dust and light impurities. For more information about the advantages of OBC-355C, see the plant’s website.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

In the self-propelled grain cleaner ОВС-25D, cleaning is carried out not on 8, but on 9 sieves. The presence of an additional sieve allows better separation of pure grain and impurities. An additional sieve is installed in the housing of the auger of feed waste and divides them into two parts by size. Due to this, the ОВС-25D grain cleaning machine divides the grain into 4 fractions, and not 3 as ОВС-25 with 8 sieves. ОВС-25D has a capacity of up to 25 tons per hour. ОВС-25D, like other models of ОВС-25 grain cleaning machines we produce, is a self-propelled machine. ОВС-25D independently rides and loads itself with grain without the help of other mechanisms or personnel. Loading is carried out by a chain elevator, which is located in front of the ОВС-25D and picks up grain at a width of 5.3 meters. Grain cleaning in ОВС-25D is carried out both by regulated air flow and sieves, which allows to obtain high quality cleaning.

Request for a quote

SILOS SPAIN INSTALACIONES, S.L.

Spain

Efficient post-harvest handling of rice ensures food security. Keep rice clean, dry, and undamaged during storage. Factors to consider: -Moisture content: Aim for ≈ 25% at harvest. -Temperature: High temps promote fungi growth and oxidation. -Storage period: Shorter is better; clean grain before storage. -General condition: Check for broken seeds, impurities, and more. Post-harvest processes include reception, cleaning, drying, and storage. To maintain quality: -Reception: Analyze heat, moisture, and impurities. Use insect control measures and an aspiration system. -Cleaning: Install an integrated system with a magnet separator, drum sieve, grain precleaner, grain cleaner, and buffer silos. Ventilation and exhaust fans are crucial. -Drying: Reduce moisture to safe levels. Prevent discoloration, loss of germination, freshness, and breakage. -Storage: Popular options are steel silos, concrete silos, warehouses, and bag silos. Optimize storage with proper management.

Request for a quote

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is designed to remove large and small size impurities, paper, straw, beans, peas, corn and sand from wheat and all other cereals

Request for a quote

GARNEC LLC

Russia

The most popular use of rye flour is making bread from it. It is also often used to make pies, pancakes, muffins, cakes and other pastries. Rye flour is distinguished by its unique aroma and fewer calories, that is why it gained popularity among people who stick to a weight loss diet. Rye flour contains vitamins B, PP, and vitamin E a source of youth and beauty. An extra feature of this flour is that it is wholegrain, i. e. when milling the shell, which contains a variety of vitamins and minerals, is not separated from the grain. Cold milling technology (t < 40°C) allows to retain most of the vitamins and minerals.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

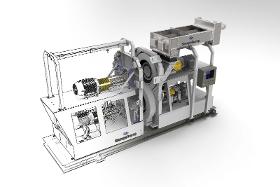

The EcoPulser by Siempelkamp uses a completely new almost wear-free, bladeless process to achieve an additional size reduction of chips and particles. Shock waves, generated by interferences of wavefronts aect the bulk material by breaking up its structure. Even the most abrasive particles can be processed using this non-contact treatment because the particles are broken up in the air. The EcoPulser disintegration bases on two counter rotating impeller wheels, which generate by their fast rotation extreme air oscillation and negative pressures. This air current takes in the chips or particles through the rotor so that their wood cells lled with air, water or ice tear apart by the negative pressure impact with the bres separating along their grain. The length of the wood bre nearly remains unchanged thus ensuring a higher board stability

Request for a quoteResults for

Grain separator - Import exportNumber of results

24 ProductsCompany type