- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- grain conveyor

Results for

Grain conveyor - Import export

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The powerful PZM-170 grain thrower has productivity up to 170 tons per hour. With its help it is possible to carry out quick loading of grain into grain carriers, cars, railway cars, containers, barges, trailers, etc. The grain thrower PZM-170 also quickly loads and unloads both low and high grain stores. Another important function that the PZM-170 can perform is the transfer of grain in closed warehouses and in open areas. This is necessary for long-term storage of grain. In the process of grain transfer, its moisture content and contamination by light impurities are reduced. Main advantages of using grain throwers: - versatility - used for loading any transport, storage of any grain in piles up to 9 m high; - energy efficiency and gentle handling of grain; - ability to move by itself and load itself with grain without help of other machines or people; - easy and convenient for people operation and maintenance; - reliable construction with the use of available components.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-60 self-propelled grain loader combines the advantages of a PZM-120M grain thrower and an auger grain loader. The grain loading speed and loader capacity are quickly regulated and range from 10 to 70 tons per hour. Unlike a conventional auger, PZM-60 moves independently and loads itself with grain with the existing scraper feeders. The pick-up width is adjustable and reaches 6 meters. During operation of the PZM-60 grain loader, there is practically no dust. The grain loading height is adjustable and ranges from 2.7 m to 4.27 m. The auger is installed on a special platform that rotates 280 degrees around its axis. This allows you to change the direction of grain loading in 2 seconds. The screw rotation speed is easily adjusted by the installed frequency converter. It is also possible to install a hopper on the PZM-60 screw loader. There is also the possibility of using PZM-60 for moistening grain by installing additional nozzles and a hydraulic pump.

Request for a quote

ROBINSON CO.

Turkey

The Conveyor used in grain, creals and food processing plants in the transport unit. Tube Conveyor is used for the horizontal transporttation of products in flour plants. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants ◾ Grain warehouses and silos ◾ Malt Factories

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: DQ06696/DQ24433/DQ08708/DQ41010 Model: 1450/1550/1165/1175/1570 7100/7300/7500/7700 CWS/WTS Brand: Donghua

Request for a quote

HARVEST TRADING CHAIN COMPANY

Turkey

John Deere Grain Elevator Chain, John Deere Lexion Grain Elevator Chain, John Deere Harvester Combine Chain, John Deere Wheat Chain John Deere Conveyor Chain Orjinal No: AZ46273 Model: 2054/2056/2058 Brand: Donghua

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The grain thrower PZM-120M is an ideal machine for fast loading of any grain into any transport. PZM-120M grain thrower is also used to transfer grain from one place to another. During the transfer process, moisture and light impurities are partially removed from the grain. Transfer of grain is necessary during its long-term storage. PZM-120M grain loader quickly loads grain into grain carriers, automobiles, railway cars, containers, barges, trailers, etc. A full load of a grain truck takes about 15 minutes. The grain thrower PZM-120M is used to work with grain, oilseeds, legumes and industrial crops, while the trauma to the grain is minimal (less than 0.1%). During the operation of the grain thrower, the grain is fed to the conveyor using scraper feeders. The conveyor loads the grain into the trimmer, which throws it through a special guide tube. The trimmer with the pipe easily rotates 257 degrees. Changing the direction and height of grain flight is carried out in less than 3 sec.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

The PZM-170P mobile handler with a conveyor is designed to receive any grain, seeds, granules, pellets in a granary, grain cleaning complex, as well as quick transshipment of bulk cargo from trucks, trailers and other vehicles to any loaders, ships in the port, on the railway or in any other place. This portable handler can also be used to transfer grain from grain trucks to other transport equipment, elevators, augers, belt conveyors, big bags, etc. We produce a whole range of mobile grain loaders designed for use in farms, grain receiving points, elevators, ports on the railway and just in the field. They differ in volume, overall dimensions and adaptation to different models of conveyors. Portable grain loaders of our production have a simple reliable design. The productivity of a mobile grain handler depends on the type of grain or other bulk cargo and reaches 200 tons per hour. Electricity consumption for reloading 1 ton of grain is only 0.04 kW.

Request for a quote

PLANT OF AGRICULTURAL MACHINERY

Ukraine

ОВС-70L is a self-propelled high-performance hybrid of a grain cleaning machine and a grain loader. The main difference between ОВС-70L and ОВС-70M4 is that the ОВС-70L has an elongated unloading elevator, but there is no trimmer and sieves. Cleaning grain of any humidity or contamination is carried out using an aspiration system and a mesh conveyor. For better grain cleaning, a self-propelled grain cleaner OBC-70M4L is used. At ОВС-70L, the cleaned grain is not conveyed by the conveyor to the trimmer, but directly to the trailer, big-bag, hopper, or poured down. Functions performed by the self-propelled grain cleaner ОВС-70L: - cleaning grain heaps of legumes, grains, cereals, corn, sunflower, rapeseed, sorghum, etc .; - loading grain directly into vehicles with a side height of up to 3 m; - loading grain into big bags, bags, bins, loader buckets, etc.; - mechanical shoveling of grain, accompanied by its simultaneous cleaning, as well as partial drying in open areas or granaries.

Request for a quote

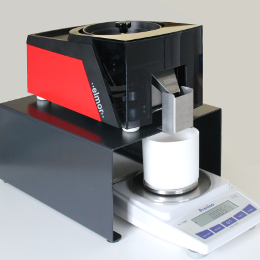

ELMOR

Switzerland

With seed tests the 1000 kernel weight is an important quality criterion, which must be determined with high accuracy. Counting and dosage of mechanical and electronic small articles as SMD’s are made increasingly also over the determination of the 1000 grain weight. By means of an additional software module, an electronic balance and a special frame, our precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Technical data Scales are available with a resolution of 1 mg, 10 mg or 100 mg. The data of the elmor C3 seed counter and the scale are sent to the control computer via two RS232 ports or – on request – with two USB cables.

Request for a quote

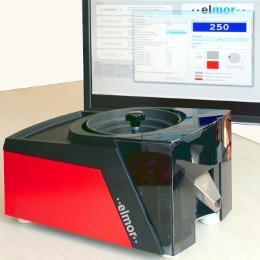

ELMOR

Switzerland

The PC controlled, high sensitive elmor C3 Seed counter is preferably used in scientific counting tasks in laboratories Universities, research and breeding projects or in seed quality control etc. Parts that can be processed with the C3 seed counter are, for example: Dust fine plant seeds such as Arabidopsis thaliana or Begonia semperflorens Vegetable seeds, grains or seeds of ornamental plants Insects, pupae and eggs Small mechanical parts Pharmaceuticals Semiconductor chips etc. The C3 Counter is controlled solely via PC. Thus new solutions for the ever growing demands of the customers are possible. All settings and the results of all operations are logged and saved . This is an essential prerequisite for quality control and traceability of test results. The parts that can be counted with the C3 seed counter can be extremely small and irregularly shaped. Thus they are very difficult to handle manually. Dosing these parts with scales is often flawed or impossible. Therefore the use of the of C3 opens new options, since e.g. smallest parts in the sub-milligram range can be dosed faster and more accurately by counting than weighing the pieces. With additional software modules also further evaluations can be performed. These are currently: direct 1000 grain weight determination and the grain size analysis. Technical data Counts Parts from 0.1 to 18mm in diameter For spheres of 2mm diameter: Counting rate: 50’000 parts per hour Typical counting error: less than 1/1000 Runs under Windows XP/7/8.1 Free Serial Port (RS232) or USB needed Software included Totalizer Preset Counter Additional software available: Direct determination of the 1000 Kernel Weight Analysis of the size of the counted particles: Particle Size Analysis Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Automatic 1000 Grain Weight Measurement By means of an additional software module, an electronic balance and a special frame, the precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 500 or 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without no arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. But most important is that in this procedure the particle size selection is impossible. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Particle Size Analyzer The precision seed counter C3 can be used as particle size analyzer to determine the particle size distribution of a given sample by means of a special software module. The size of the singularised and free falling parts is measured in one dimension with a resolution of some 1/100 mm. This measurement is intended primarily to compare different samples qualitatively. With spherical parts the measurements give also quantitative information. The measured values of the particle size analyzer are stored as txt file. This makes it possible to further process the raw data individually by means of appropriate standard software. Filling Carousel The C3 parts counter can be combined with the elmor 780 carousel filler. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowls of our counting machines C1, C3 or CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity Click here to add your own text Click here to add your own text

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Beige 35 – wear protection rubber with CN layer germanLine® Beige 35 protects surfaces against wet wear and round grain as well as fine-grained, sharp or hard conveyor goods or slurries, such as wet grit. germanLine® Beige 35 wear protection rubber has, on one of its sides, a CN contact layer that ensures super-strong adhesion to steel bases. Our product is used in granulation drums, bunkers, skids or slides, pumps, skirts, chutes, silos etc. and serves as wear protection, shock absorber, sound insulation, protection against corrosion and caking. germanLine® Beige 35 wear protection rubber with CN layer is high in natural rubber and has excellent physical parameters, especially in terms of abrasion resistance. ... more

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanLine® Beige 35 with CN Layer Applications: germanLine® Beige 35 with CN layer protects surfaces against wet wear and round grain as well as fine-grained, sharp or hard conveyor goods or slurries, such as wet grit. Our product is used in granulation drums, bunkers, skids or slides, pumps, skirts, chutes, silos etc. and serves as wear protection, shock absorber, sound insulation, protection against corrosion and caking. Available dimensions: Thickness: 4 / 6 / 8 / 10 / 12 / 15 / 20 mm Width: 1,500 / 2,000 mm Available length: 10 / 20 m Specifications: Colour: beige Density: 1.0 ± 0.03 g/cm³ Hardness: 35 ± 5 ° Shore A Tensile strength: ≥ 19 MPa Elongation at break: ≥ 650 % Abrasion: ≤ 95 mm³ at 5 N Breaking force: ≥ 50 N/mm Downloads: Technical Data Sheet germanLine® Beige 35 with CN Layer - Englisch [PDF]

Request for a quoteResults for

Grain conveyor - Import exportNumber of results

13 ProductsCountries