- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wrap around labels

Results for

Wrap around labels - Import export

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The TNC-DS series is used to label cylindrical products on the circumference. For this purpose, the product is manually placed in the product turning station. The labelling process is triggered by actuating the foot switch or the optionally available 2-hand control. The product is rotated, and the label is applied precisely to the circumference of the label. As standard, the model is available with different roll widths (100 to 300 mm) and different label applicators (60 to 250 mm wide) or print- and apply systems. Optionally, the labels can be aligned using a welding seam or other product features. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Depending on the operator, the output of this model is between 10 and 15 products/min.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

For precise labelling, products with an accessible cavity are manually placed on a format mandrel. By actuating the foot switch or the optionally available 2-hand control, the labelling process is triggered, the product is rotated, and the label is applied precisely to the circumference of the product. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Optionally, the labels can be aligned using a welding seam or other product features (such as opening tabs or lid recesses for tubes). A pneumatic ejection makes the removal process superfluous and blows the well labelled products into a collection box

Request for a quote

HERMA GMBH

Germany

HERMA 211 HC - Feeding demand for personalized medical care The wrap-around labeler 211 HC reliably processes even the smallest batches and products that tend to tip over. Ideal machine for small vials, syringes and cartridges, where the semi-automatic machine can score with its economy in frequent format changes. Labels are applied by rotating these products horizontally between two motorized rollers and the pivot peel plate with application roller. The semi-automatic labeling machine combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications, including a printer for variable data and codes, and a camera for print and code verification. Optionally available with the innovative bad label return for the reliable removal of bad labels. The new 211 HC is therefore tailor-made for processing healthcare products.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Labelling machine for wrap-around labelling Basic concept of the system for bottle labelling and can labelling: With the aid of the fully automatic VRM labeller, different cylindrical or square products can be labelled quickly and precisely on the circumference - wrap-around labelling. The machine is therefore used in many industries, from pharmaceuticals to food and cosmetics. The VRM series is suitable for bottle labelling, can labelling, vial labelling or for comparable containers such as jars or bottles. Several different formats can be covered simultaneously with one model. The VRM-DS labelling system includes a 3-roll turning station and is used for outputs of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the containers on the basis of a weld seam, print mark or other feature before labelling (target labelling).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RML labeling machine is suitable for wrap-around labeling of non-rigid cylindrical products - ampoule, cartridge, syringe labeling. The products are transported to the labeling station, which fixes the label on the circumference, by means of an intermittent roller conveyor. The labeling system is suitable for products such as ampoules, cartridges, lipsticks, syringes and vials and is therefore suitable for the pharmaceutical, medical technology, cosmetics and food industries, where reliable labeling and control processes are extremely important. Deviations and errors here can lead to life-threatening situations. From manual loading and unloading to fully automatic loading and subsequent collection of the products, this model is modularly expandable. Particularly narrow products such as ampoules or cartridges can also be processed using format sets (RML-FS).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

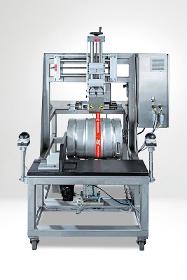

The TNC-GG model series was developed to apply one or more labels to large cylindrical containers at the circumference. Instead of using „die-cut“ labels, it is also possible to handle continuous label material from the roll. Depending on the size of the product, the material is cut inside the system. The largest area of application for these systems is in the beverage industry, where beverage barrels (KEGs) are provided with a deposit banderol on the circumference and thus clearly indicate the owner of the returnable containers. Highly permanent label material is used for these applications, which can no longer be removed from the product without leaving residues. We also offer fully automated solutions for this.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Like all of our labelling systems, this model has a modular design and can be expanded at any time. The advantages such as low set-up costs, high availability and multiple use in different production lines are obvious. The adaptation to the different products takes place by simple adjustment of the machine components and is possible without tools. The VRM-DS model includes a 3-roller turning station and can be used for an output of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the products using a welding seam, print mark or other feature before labelling (target zone labelling). For larger quantities of up to 250 products/ min the VRM-RB model is used. Model: VRM-DS | Cylindrical and quadratic products | up to 60 products/min VRM-RB | Cylindrical and quadratic products | up to 250 products/min VRM-DSRB | Cylindrical and quadratic products | up to 250 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to lower storage costs and higher flexibility, more and more manufacturers rely on the processing of unprinted tubes and mark them with a label directly before filling. The labeler TEM model was developed for this purpose and is able to apply a label to the circumference of the empty, unsealed tubes. For this purpose, the products are transported via a clocked transport system to the labeling station, where they are previously aligned and stabilized by means of a format-specific mandrel. The model can optionally be extended to include infeed and outfeed magazines and/or steep conveyors into the tube filler. As a double-cycle variant, throughput can be doubled. Special sensor technology makes target labeling possible based on print marks or lid features. Models: TEM \ Empty, unsealed tubes \ 50 - 60 products/min TEM-2T \ Empty, unsealed tubes \ 100 - 120 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The semi-automatic labeling machine TNC-R was developed for the all-round labeling of tubes. Small batches can be labeled quickly and precisely with the labeller. The tubes are placed manually in the labeling system. As soon as the 2-hand operation is activated, the automated labeling process starts. The product is rotated and shifted, then the wrap-around label is applied exactly to the product. A printing unit can be integrated for individual labeling of the tubes. You can easily print the labels yourself inline. The integration of a printing unit is suitable, for example, for laboratory tubes or sample vessels that have to be provided with individual data.

Request for a quote

PARTEX MARKING SYSTEMS GMBH

Germany

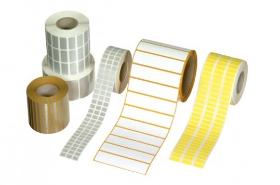

PLL is a serie of label sheets in A4 format, with matt surface, primarily for laser printing. Its material is UL-approved adhesive polyester for indoor and outdoor use. The PLL range also includes adhesive, self-laminating and printable wrap-around labels. Its material is UL-approved MT310 transparent polyester. The additional transparent part is wrapped around the cable and laminates the print field and protects the marking against chemicals and wear. Material UL approved polyester with acrylic adhesive UL approved MT310 transparent polyester with adhesive Colours Yellow, silver, white Wrap-around: yellow, white Print Printable in standard laser printers Temperature range Service temperature range: –40°C to +150°C (–40°F to +302°F). Minimum application range: +10°C (+50°F). Storage stability: Two years stored at +21°C (+70°F) and 50% relative humidity (RH). Resistance UL code PGGU2. Excellent resistance to isopropyl alcohol, oil and water.

Request for a quote

PARTEX MARKING SYSTEMS GMBH

Germany

PLT is a serie of labels primarily for thermal transfer printing. Its material is UL approved self adhesive polyester. 1-track or 3-track, 38 mm (standard) or 76 mm core diameter and perforated. The PLT range also includes adhesive, self-laminating and printable wrap-around labels. Its material is UL approved MT310 transparent polyester. Material UL approved polyester with acrylic based permanent adhesive. UL approved MT310 transparent polyester with acrylic based adhesive (wrap-around) Colors yellow, silver, white yellow, white (wrap-around) Print Printable in recommended standard thermal transfer printers with standard label design software. Temperature range Service temperature range: –40°C to +150°C (–40°F to +302°F). Minimum application range: +10°C (+50°F). Storage stability: Two years stored at +21°C (+70°F) and 50% relative humidity (RH). Resistance UL code PGGU2. Excellent resistance to isopropyl alcohol, oil and water.

Request for a quote

HERMA GMBH

Germany

Uncompromisingly fast and reliably effective Primarily designed for round pharmaceutical products, such as glass vials and the corresponding high batch sizes in the healthcare industry Wrap-around labeler 132M HC for healthcare products with a high-speed output of up to 400 products per minute High labeling speed with extreme precision thanks to the new HERMA 500, our high-performance applicator It is completely equipped for all healthcare tasks, including a selection of various printing and control systems, an patented automatic label return with cross check, as well as one of several possible product reject stations New innovative HERMA rotary tables, electronic position indicators and format sets that can be exchanged without tools for fast format changes ensure maximum overall equipment effectiveness The 132M HC can be easily configured for numerous industry applications - even without printers and control systems in the version 132M

Request for a quote

HERMA GMBH

Germany

HERMA wrap-around labeler 152C: precise labeling at low cost Equipped with the high-performance labeler HERMA 500, it is suitable for up to 200 cylindrical products per minute The easy-to-maintain solution with a folding belt and back pressure plate offers amazing performance and a fast return on investment Most adjustments can be made without tools with little time required With the optional roller prism technology, even spiral misalignment is almost completely eliminated; even aligned labeling succeeds perfectly Clean Design with closed holes, minimum gaps and grooves, and rounded corners protects the 152C from contamination and makes it easy to clean and maintain Installation of a printer unit such as a hot stamp or thermal transfer printer is possible without any problems Is now available much faster due to the Clean Design and digitized ordering processes, optionally in EU or US versions.

Request for a quote

HERMA GMBH

Germany

High performance without compromise The wrap-around labeler is available in two versions: HERMA 132M - With the continuously rotating starwheel, up to 400 products/minute can be labeled. HERMA 040M - With the clocked starwheel, up to 120 products/minute can be labeled: Precision and reliable production make this easily convertible solution unbeatable - the clocked rotary star guarantees precise labeling with extreme performance. The compact, modular design from standard components enables the machines to be precisely and yet very economically assembled for individual requirements of individual users. Cylindrical products with one or two labels on the circumference can be labeled more cost-effectively and in less time. In addition to cost-effectiveness, the labeling system for wrap-around labeling offers a high standard of safety.

Request for a quote

HERMA GMBH

Germany

Compact, precise and cost efficient Businesses often face a difficult decision: If the dimensions of your products are ordinary, can you get by with an inexpensive and compact standard system with little scope for expansion? Or does the application require a more complex and expansive custom machine with longer lead times because you need to integrate various printing and control systems? The HERMA 152E wrap-around labeling system offers you the best of both worlds. Despite its compact size, the system covers a wide range of possible product dimensions. In addition to its applications in the pharmaceutical industry, the HERMA 152E is a do-it-all machine for a wide range of industries. With the 152E you get a complete package with superior performance for labeling all sorts of cylindrical products, for instance vials, bottles, canisters and cans.

Request for a quote

HERMA GMBH

Germany

Compact and stable labeling machine that works virtually without format parts and yet covers a very wide range of product formats. Flexible, quick and easy to retool for precise side labeling. High efficiency combined with low investment costs. Two high-performance applicators ensure a high output, even during continuous operation. The 362C two-sided labeler allows you to label up to 200 products per minute. Its compact design makes it suitable even for difficult installation situations. The machine can be converted for wrap-around labeling in no time at all.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HERMA GMBH

Germany

HERMA 362M - Two-sided labeling with maximum precision: For labeling challenging product shapes. The 362M two-sided applicator allows you to label up to 200 products per minute. Versatile, robust and extremely precise. Precise labeling in the centered position is also possible as an option. Two high-performance applicators ensure maximum throughput, even during continuous operation. The labeling machine can be converted for wrap-around labeling in no time at all. With an operating concept for quick format changes and a variety of equipment options, the 362M leaves nothing to be desired. For the highest product quality thanks to various print and label presence controls in conjunction with bad label return and product ejection features.

Request for a quoteResults for

Wrap around labels - Import exportNumber of results

19 ProductsCountries

Company type