- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electronics industry

Results for

Electronics industry - Import export

BIEGLO GMBH

Germany

BIEGLO offers PEEK micro-mold parts up to 12mm in the largest dimension. Our smallest part to date is roughly 800µm x 300µm x 380µm and the thin wall section near 0.1mm. The feature aspect ratios around 6:1. In addition, the part volume 0.08 cm3 or less, the gate size as small as Ø0.1mm and the ejector pins as small as Ø 0.254mm. PEEK micro-mold parts must have a gate and ejection location consideration and the material selection can greatly affect the fill and definition of features.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers finished or semi-finished parts directly formed from polyimide powder with all the attributes of sintered PI. The advantage of direct formed parts are the lower costs as quantitiy is increasing. Due to almost zero percent waste during production it can be a more economic production method. Machined parts are widely used for small series high precision applications. Polyimide direct formed parts can be used in different applications: Automotive industry: racing engine fuel line. Jet engine: vane bushing or lock nut insert. Industrial machinery: hotrunner systems nozzles or plasma cutting torch as gas distributers or sealing components. Semicon HDPCVD Equipment: e.g. heater coil spacer. Life sciences: rotor seal or pneumatic surgical tool vane.

Request for a quote

BIEGLO GMBH

Germany

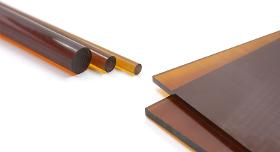

Polyetherimide is an amorphous thermoplastic and part of the polyimide family. It has excellent dimensional accuracy over a wide temperature range and has low thermal expansion. BIEGLO's sales portfolio for PEI contains rods from 8mm to 100mm. The most common applications of PEI are in the food and beverage industry, pharmaceutical and electronics industry as well as precision engineering.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO is the official distributor of Saint Gobain Performance Plastics for the Meldin 7000, Polyimide rod. In line with different requirements of the Industrial market, the Meldin product family can provide high temperature resistance, wide chemical resistance, good mechanical properties also at elevated temperatures and low wear, long lifetime. Polyimide rod can be used in temperatures up to 350°C continuously and it has various applications in the automotive, aerospace and electronic industries. Polyimide rods have a standard length of 965mm. The diameters of the solid bars are distributed from 6.3mm to 82.5mm.

Request for a quote

BIEGLO GMBH

Germany

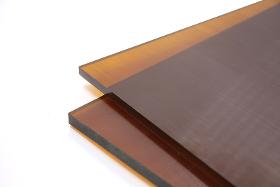

BIEGLO's sales portfolio for PEI contains also sheets from 8mm to 100mm as well as, PEI thin films below 1mm thickness are also available and the maximum width is 1200mm for sheets and film. Polyetherimide is an amorphous thermoplastic and part of the polyimide family. It has excellent dimensional accuracy over a wide temperature range and has low thermal expansion. PEI is naturally flame retardant and has a fire rating of UL94 V-0. The most common applications of PEI are in the food and beverage industry, pharmaceutical and electronics industry as well as precision engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIEGLO GMBH

Germany

Polyetherimide has recently joined the BIEGLO portfolio. Our sales portfolio for PEI contains rods and sheets from 8mm to 100mm diameter. As well as, PEI thin films below 1mm thickness. The maximum width is 1200mm for sheets and film. Polyetherimide is an amorphous thermoplastic and part of the polyimide family. It has excellent dimensional accuracy over a wide temperature range and has low thermal expansion. PEI is naturally flame retardant and has a fire rating of UL94 V-0. The most common applications of PEI are in the food and beverage industry, pharmaceutical and electronics industry as well as precision engineering.

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

SEPARO A solder recycler for the electronic industry The solder recycler SEPARO is designed to capture and process dross for reuse. Dross, a side effect of the solder process requires special handling that is very costly. This unit not only provides considerable savings but has the added benefit of being right in your own manufacturing environment. SEPARO is primarily used in the electronic industry but has proved, by eliminating the outsourcing, to be very useful in other parts of the tin processing industry and the consequent disposal of alloy waste SEPARO activates the specific weight of the materials that are to be separated. After a filtering process the reusable alloy settles in the lower section of the pot while the dross floats on the surface.

Request for a quoteResults for

Electronics industry - Import exportNumber of results

8 ProductsCompany type