- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding machines

Results for

Welding machines - Import export

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of mobile equipment for cutting and welding metal. Our products are designed to offer the highest precision and flexibility wherever they are needed. From pipe cutting devices to hand-held flame cutting machines to portable oxy-fuel technology - we have the solution for your requirements. RSV pipe cutting devices Our mobile pipe cutting devices enable the simultaneous cutting and beveling of steel pipes. Thanks to the quick-clamping device, they can be fixed in any position, offering maximum flexibility and efficiency. The cutting torch can be rotated by 45°, adjusted in height and sideways and can optionally be motorized. Hand-held flame cutting machines ZINSER's mobile hand-held flame cutting machines are designed for daily use. They offer precise and reliable cuts with maximum user-friendliness. ZINSER oxy-fuel technology ZINSER has been involved in the economical use of acetylene and other gases for over 100 years.

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Menu: selection of various languages Constant current regulation Repeat cycle lock Steel housing, powder-coated Shielding gas equipment: standard Stud counter (Daily and total counter) Process control Perfectly tuned for weld guns of the SK- and K-series

Request for a quote

KÖSTER & CO. GMBH

Germany

Stud welding equipment with capacitor discharge Suitable for welding steel, stainless steel, aluminium and brass Weldable stud range 3-8 mm stud diameter Continuously adjustable charging voltage Digital display of charging voltage Weight only 8,9 kg Steel housing, powder-coated

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfuction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Shielding gas equipment Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Stud welding equipment with capacitor discharge Suitable for welding steel, stainless steel, aluminium and brass Weldable stud range 3-10 mm stud diameter Continuously adjustable charging voltage Digital display of charging voltage Weight only 9,9 kg Steel housing, powder-coated

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control,mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection Special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages Two gun connection for stud welding guns

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control,mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection Special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages Two gun connection for stud welding guns

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control,mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection Special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment: optional Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Self-diagnosis: Overheating, short circuit control, mains phase failure and malfunction of pilot arc Fully controlled power source with thyristor bridge Microprocessor controlled Constant current regulation Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Shielding gas equipment Stud counter: standard Interface for automatic components: optional Menu: selection of various languages

Request for a quote

KÖSTER & CO. GMBH

Germany

Fully controlled power source with thyristor bridge For threaded studs up to 8 mm Designed for welding on building sits Self-diagnosis: Overheating and mains phase failure, short circuit control, malfunction of pilot arc Microprocessor controlled Repeat cycle lock Mains connection special voltages (V): optional Dust and moisture protection of control unit Steel housing, powder-coated Stud counter: standard

Request for a quote

EWM AG

Germany

— Modular plasma/TIG welding machine with Comfort 2.0 P control — Plasma and TIG welding — Plasma and pulsed TIG welding — Plasma and pulsed TIG welding up to the kHz range allow a high welding speed with minimal heat input using a constricted arc — Plasma and TIG welding current adjustable in 0.1 A increments — Pilot arc current adjustable in 0.1 A increments between 2–15 A — The pilot arc current can be adjusted at four operating points during the welding process (beforehand, during, and following welding, as well as during pauses in welding) — Non-latched/latched operation — Spot welding/tack function (spotArc/spotmatic) — Spotmatic – reduce the time required for tacking by up to 50% (TIG only) — Adjustable up-slope and down-slope time — 3.5 m mains supply lead with 16 A shock-proof plug

Request for a quote

EWM AG

Germany

Maximum operating convenience, long service life and all pulse, standard and innovative welding processes optimised and included in the machine at no extra charge. The members of the Titan XQ family are taking a quantum leap in welding technology. Here, perfect weld seams are already pre-programmed for low- and highalloy steels and aluminium in all material thicknesses and all positions. Thanks to the many options and accessories for the Titan XQ puls series, you can put together your machine in the way that best suits you, your needs and your applications. An exceptionally long duty cycle of 100% at up to 320 A, for example, makes for effective working. Perfect welding becomes sustainable – 24 hours a day, 7 days a week.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EWM AG

Germany

— MMA inverter welding machine with degaussing function and reversing switch — MMA /MMA pulse — TIG lift arc / pulse — GMAW (MIG/MAG) welding with Pico drive 4L or Pico drive 200C wire feeder — Arcforce, Hotstart, Antistick — CC / CV characteristics — Suitable for flux cored wire welding — Welding polarity can be reversed by pressing the button polarity reversing switch — Stick electrode/MMA cellulose electrodes: 100% safe for vertical-down welding

Request for a quote

EWM AG

Germany

— Degaussing of pipes and metal sheets — Automatic degaussing before welding — Dependable degaussing for better welding results through stable welding process without magnetic deflection, minimisation of finishing work — activgauss (10–250 A) – degaussing during welding: — Avoids moving up of magnetic field during the welding process in case of very long and strongly magnetised components — Portable and robust — Quick connection at the pipe by means of three load cables — Use at -25 °C to +40 °C with mains voltage tolerances of +/- 20% Advantages of degaussing: — No deflection of the arc by residual magnetism in the workpiece — Prevention of lack of fusion due to insufficient sidewall fusion — Minimisation of finishing work — Cost-efficient and high-quality results — Set: Degauss 600 degaussing machine, two 5-metre, 35 mm² load cables, one 20-metre, 35 mm² load cable, RT DGS1 remote control and 5-m connection cable

Request for a quote

EWM AG

Germany

— Gas-cooled DC TIG inverter welding machine — TIG welding with high frequency starting — TIG lift arc welding without HF — MMA welding — MMA pulse welding and pulsed TIG welding up to 2 kHz — Reduced secondary current accessible using torch trigger — Adjustable up-slope/down-slope — Adjustable gas pre-flows/post-flows — Adjustable hot start current and hot start time — Adjustable Arcforce — Antistick function — Energy-saving thanks to high efficiency and standby function — Portable, including shoulder strap — 3.5 m mains supply lead with 16 A shock-proof plug — Mains connection 230 V/16 A — High mains voltage tolerance +15%/-40% and therefore fully generator-compatible — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quote

EWM AG

Germany

Maximum operating convenience, long service life and all pulse, standard and innovative welding processes optimised and included in the machine at no extra charge. The members of the Titan XQ family are taking a quantum leap in welding technology. Here, perfect weld seams are already pre-programmed for low- and highalloy steels and aluminium in all material thicknesses and all positions. Thanks to the many options and accessories for the Titan XQ puls series, you can put together your machine in the way that best suits you, your needs and your applications. An exceptionally long duty cycle of 100% at up to 350 A, for example, makes for effective working. Perfect welding becomes sustainable – 24 hours a day, 7 days a week.

Request for a quote

EWM AG

Germany

— GMAW standard and pulsed welding — Synergic characteristics for steel, CrNi and aluminium — MMA welding and TIG liftarc welding — Perfect for welding self-shielding flux cored wires — Infinitely adjustable arc dynamics (choke effect) — Synergic or manual welding operation — Interval welding — Adjustable gas pre- and post-flow time — Portable, compact — Saves power through highly efficient performance — Robust casing suitable for construction site use — 4-roll drive for 0.8 mm and 1.0 mm steel wires — Easy, tool-free change of welding polarity — IP23 spray water protected — Wire spool diameter up to 200 mm/D200 — 3.5 m mains supply lead with 16 A shock-proof plug — Mains connection 230 V/16 A — High mains voltage tolerance +15%/-40% and therefore fully generator-compatible — Free WPQR package for certification up to and including EXC2 in accordance with EN 1090 and for welding of unalloyed steels up to and including S355

Request for a quote

EWM AG

Germany

— Inverter welding machine, DC — Very light-weight, only 4,7 kg – housing made of aluminium and impact-resistant plastic — Portable, shoulder strap — MMA and TIG lift arc welding — Cellulose electrodes: 100% safe for vertical-down welding — Welding of stick electrodes up to 4 mm — Pulsed MMA welding: — Especially suitable for root welding — Outstanding gap bridging with no sagging of the root side — Fine-flaked weld surface with a TIG look for final passes — Less finishing work thanks to less spatter — Ideal for difficult electrodes — Less distortion thanks to controlled heat input — Pulsed TIG welding with up to 2 kHz — Connection capability for remote control — IP23 spray water protected — Arcforce, hot start, antistick — Energy efficient due to standby mode — 3.5 m mains lead with 16 A earthed plug — Overvoltage protection: No damage to machine caused if inadvertently connected to 400-V mains voltage

Request for a quote

EWM AG

Germany

Water-cooled PM MIG/MAG-welding-torches , optionally equipped with high-quality OLED graphic display. Available as PM 301 up to 330A, PM 451 up to 500A and PM 551 up to 650A. — Secure hold thanks to rubber inserts in the grip — The flexible ball joint makes it comfortable to work with, even in difficult spots Highlights of function torches: — Automatic LED lighting when welding torch is moved Display and adjustment directly from the workplace — Welding current and wire feed speed — Voltage correction — Program and JOB selection — Welding process switching 2-/4-stroke — Choke — Welding processes (standard, pulse, coldArc, rootArc, forceArc) Also supports the Xnet welding management software: — Selection of the welding task according to the welding sequence plan — Component management

Request for a quote

KLN ULTRASCHALL AG

Germany

Basically the TOOLMASTER versions vary by their tool design, their size of useable surface and the degree of automation. All versions are suitable for high temperatures and optionally equipped with fire protection engineering, which quickly separates the tool in case of energy drop or timeout. KLN also manufactures special machines adapted to your individual requirements. TOOLMASTER "Basic" as well as type HE 50/30 are standard machines. The versions "Advance", "Semi-Automatic" and "Automatic" are made with tools in sandwich design. This makes possible the handling of upper tool, hot plate element and lower tool as a compact unit. They are designed particularly for quick and frequent production changes. The HE/SA has a horizontal concept with servo-drive technology for quick and precise movements. The TOOLMASTER CC has been developed for applications with two welding tasks in one cycle. Almost all machine versions can be provided with pneumatic or servo-motor drives.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Welding construction as required No matter whether pipes, small parts or large components - the welding construction department of Siempelkamp Maschinenfabrik GmbH is able to fulll your wishes thanks to its high-performance machinery. Our welding specialists are able to produce your components using MIG, MAG, UP, TIG, Emanual and electro-slag processes. Numerous certicates attest to the highest quality of our welding work. Key features procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Advantages procedure: MIG, MAG, UP, TIG, E-manual, electro-slag Component weight up to 100 t Pipe forming up to Ø168.3 mm Pipe neck up to Ø270 mm Application of the most ecient welding process for your component Highest quality standards through certied welding work economic production of tubes by our forming and necking machine

Request for a quote

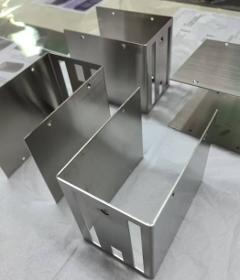

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The process of sheet metal processing: Select the appropriate sheet metal, and carry out the necessary treatment and preparation, such as cutting, bending, stamping, etc Processing stage: forming the metal sheet, including cutting, bending, stamping, welding and other process operations Inspection stage: Conduct comprehensive quality inspection and evaluation of the final product, including appearance inspection, size inspection, performance testing, etc

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

ROTAWELD is our platform to cover a wide range of applications requiring circumferential seam welding. The precision servomotor rotation axis combined with our advanced control system form the basis for the production of accurate and repeatable circumferential seam welds. Machine sizes, part holders, welding equipment, torch holders and any additional positional axes are designed specific to the customer and their products.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quoteResults for

Welding machines - Import exportNumber of results

190 ProductsCountries

Category

- Laser - cutting and welding machines (140)

- Welding, soldering and brazing - equipment and supplies (11)

- Welding work - steels and metal (5)

- Welding, plastics - machinery (5)

- Steels and metals - welding and brazing (3)

- Welding, electric - equipment and supplies (1)

- Cutting - machine tools (1)

- Electromagnetic compatibility measuring equipment (1)

- Polishing - machine tools (1)

- Sheet metal and strips, tinplate (1)

- Steel (1)

- Steel & Metals (1)

- Ultrasound systems - Processing plastics (1)