- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded tubes

Results for

Welded tubes - Import export

ORBITEC GMBH

Germany

With tube-to-tubesheet weld heads, it is possible to achieve consistently high-quality, reproducible welding of tubes to tubesheets, with or without additional wire. The tubes to be welded can be flush with the tubesheet, offset, protruding or behind the tubesheet. The RBK 38 S and the RBK 60 S are our two new tube-to-tubesheet weld heads. The RBK 38 S is a small, handy water-cooled head for welding tubes to tubesheets up to an ID of 36.7 mm, without additional wire. Package includes: — Weld head — Water-cooled hose package, 6 m — Pull bar B — Gas hood ID 35 mm — 0° electrode holder — Transport case Optional: — Div. electrode holders for RBK 38 S — Div. gas hoods for RBK 38 S — Div. spring sleeves and pull bar sets for RBK 38 S

Request for a quote

ORBITEC GMBH

Germany

The RBK 60 S is an extremely robust water-cooled weld head for a standard heat exchanger application up to an ID of 60 mm, modified to an ID of 99 mm or 120 mm. The head is pneumatically centred and is available with a rotating wire device and/ or arc voltage control (AVC) as an option. The head can also be used with a pneumatic positioner instead of a balancer. Versions: — RBK 60 S weld head with pneumatic centring, including hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring and wire feeder incl. hose package, 8m, water-cooled — RBK 60 S weld head with pneumatic centring, wire feeder and AVC incl. hose package, 8m, water-cooled Package includes: — Weld head — Small torch incl. torch consumables and tungsten electrode Ø 2.4 mm — Water-cooled hose package, 8 m — Pull bar B — Transport case Optional: — Div. spring sleeves and pull bar sets for RBK 60 S — Torches, Balancer, Tube-to-tubesheet positioner...

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round SEAMLESS tubes are hot rolled and satisfy both the requirements of the norm EN 10210 for structural applications and EN 10297-1 for mechanical applications. These steel tubes are fully killed and are suitable for structural applications but with the possibility to reach up to 100 mm w.t., which is impossible for welded tubes. These tubes are used for the manufacture of various kinds of construction components, above all where heavy wall thickness are required. EN 10210-1/2 (structural applications) EN 10297-1 (mechanical applications)

Request for a quote

GSW SCHWABE AG

Germany

ideally suited for large coil widths and thicknesses dual arbors for minimal deflection hydraulic wedge type expansion systems highestquality Reel Arbor with maintenancefree bearing and minimal deflection integrated hydraulically powered coil loading system for narrower coils even onesided use possible coil reels as seperate movable components proven support of large rollforming applications especially for the manufacture of welded tubes SHZR Series with variable speed drives via threephase motors and frequency inverter

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The different kinds of cold drawn tubes ready on stock cover a wide range of applications: COLD DRAWN SEAMLESS AND WELDED TUBES SUITABLE FOR HONING. COLD DRAWN SEAMLESS AND WELDED TUBES INSIDE H8. COLD DRAWN SEAMLESS TUBES FOR SHAFTS. WELDED SMOOTH BORE CYLINDER TUBES INSIDE H9 OR H10. COLD DRAWN SEAMLESS TUBES FOR HYDRAULIC AND PNEUMATIC POWER SYSTEMS. Seamless and Welded Cold Drawn pipes honed or ready for honing; H8, H9 or H10. STEELGRADES AND DELIVERY CONDITIONS COLD DRAWN / HARD (+C acc. EN 10305 / BK acc. DIN 2391) No heat treatment after final cold drawing. COLD DRAWN / SOFT (+LC acc. EN 10305 / BKW acc. DIN 2391) The final heat treatment is followed by a suitable drawing pass (limited reduction of area). STRESS RELIEVED (+SR acc. EN 10305 / BK+S acc. DIN 2391) After the final cold drawing process, tubes are stress relieved in controlled atmosphere in order to reduce work hardening due to the cold forming process. ANNEALED (+A acc. EN 10305 / GBK acc. DIN 2391) After...

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK tube connectors – the flexible alternative to welded connections The clampable tube connectors from RK Rose+Krieger are a cost-efficient solution for the positive and ready detachable connection of a diverse variety of systems – without the need for drilling and welding. Depending on the field of application and the expected load, RK Rose+Krieger offers tube connectors made of plastic (Light Clamps), aluminium (Solid Clamps) or stainless steel (Robust Clamps). The Solid Clamps tube connector system also includes the RK monitor mounting for the fixation and ergonomic adjustment of monitors and touch screens used in industrial applications. Say goodbye to welding – that could be the motto of the clampable RK tube connectors The simple assembly technology of the clamping elements eliminates the need for time-consuming and cost-intensive drilling and welding work.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Energy systems for industrial plants can sometimes be expensive to maintain. This is why we already pay attention to economic solutions during the planning and conception of your plant. Our heating and cooling systems are needs-based, individual solutions for seasonal and user-related requirements. Heat transfer media such as water, air or oils are heated by means of large-capacity water boilers, high-speed steam generators or thermal oil systems. In the heating systems from IFA Technology, the subsequent heat transfer takes place through half-tube coils welded onto the jacket, heat exchangers, heat transfer plates (thermoplates) or electrical heating cables.

Request for a quote

FLEXOMAT GMBH

Germany

Our highly flexible vacuum hoses are produced from longitudinal seam-welded, thin-walled stainless steel tubes, which are hydraulically formed in special-purpose machines. Our vacuum hoses are specifically cleaned after metal forming, during processing protected from uncleanness and prior to dispatch shrink-wrapped. Furthermore, all vacuum hoses will be leak tested prior to dispatch, by means of helium leak testing with up to 10E-8 mbar*l/s.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Strengthen and enhance membrane performance Customized and developed for specific end-use applications, POREX ® membrane support media are used as substrates for fragile membranes to provide structural strength and enhanced performance. Available in polyethylene (PE) and various customized geometries, our membrane support media: Support fragile membrane s with a strong and durable media. Enhance performance of specific end-use applications with custom designs Materials Offered Advanced porous materials (PE) Formats Available 3D molded shapes One piece solid and welded options including tubes and sheets Customization options for specific applications Request Sample ask an engineer

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Standard elements : - Robust frame in grey or white lacquered steel - Conformator tube - Welding jaw with heating rod (hard chrome plated) with constant temperature controlled by temperature controllers with digital display - Drive of the film by belt - Motorisation of the unwinding of the roll - Control generated by SPS - Touch screen display - Programme memory (weight, length of bags...) - Fine detection of the reel - Translucent mapping Material according to current EC standards. Films that can be used: polypropylene, composite, aluminium, barrier, polyethylene.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

New employees are first introduced to TIG welding in a basic training lasting several months. Only then are the first products manufactured for customers, whereby the following topics are handled in a multi-year development process, which includes the welding test for the tube welder CrNi relatively early: Material requisition Additional materials Gas protection Interpass temperature and welding temperature Maximum material temperature during welding Cleaning the weld seam Welding distortion Mechanical seam load

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

Fittings Our manufacturing site in Switzerland produces over 100 different types of fitting under cleanroom conditions in compliance with DIN 16901-140. The fitting bodies are made of PFA, while the union nuts are made of PFA, PVDF or CPFA. We stock all the connections available on the market too. Emmen cleanroom plant GEMÜ has be producing valves and fittings at its new cleanroom plant in Emmen (Canton of Lucerne, Switzerland) since September 2012. A state-of-the-art manufacturing and assembly facility was built here when, thanks to commercial success, the capacity of our site in Rotkreuz could no longer keep up with demand. When planning and developing the facility, designers focused on creating a contemporary quality management system that is fit for the future. The result is that product and production quality are ensured, for example, by using specific inspected raw materials and through audits carried out by customers and official bodies.

Request for a quote

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 40 S is a powerful and handy squaring device for mobile or stationary use with battery or mains drive. It has a large viewing window, a tool carrier for mounting the inserts, double-sided indexable inserts, and a feed with 0.1mm scale graduation. Alternatively, existing Orbitec facing tool bits can be used without tool carriers. The new inserts have a long service life and can process unalloyed, low-alloy and high-alloy steel quickly and reliably with high precision. Package includes exemplary for Planfix 40 S battery pack 230 V: — Tube clamping attachment — Drive — 2 Li-ion batteries — Battery charger — Tool set — Carrying case

Request for a quote

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 115 S is a high-performance tube squaring and chamfering device with angle gear for mobile or stationary use with a mains drive. It has a large viewing window, a chip collector and a feed with 0.1mm scale graduation. Optionally, the device can be equipped with a tool carrier and a double-sided indexable insert holder or the well-known Orbitec L facing tool bits. Package includes exemplary for Planfix 115 S Power 230 V: — Tube clamping attachment — Drive — Tool set — Transport box

Request for a quote

ORBITEC GMBH

Germany

A precise 90° saw cut is a basic requirement for orbital weld preparation. Robust saws for all wall thicknesses Powerful drive motor Uniform and easy feed control by means of handwheel Different chamfering blades mountable Right-angled saw cut 4, 5 or 6 clamping jaws made of stainless steel as well as reducing jaws Due to concentric clamping no deformation with thin-walled pipes Also for cutting off pipe bends Quick-release fastener for easy changing of saw blades Chip removal during cutting by means of integrated brush Convenient adjustment of plunge depth by means of feed wheel Technical Data: Size range in mm: OD 6 – 220mm Size range in inch: 0.236″ – 8.661″ Wall thickness: 1 – 8mm Electric drive: Single-phase AC motor Mains voltage (input): 200/220VAC (50/60Hz) Power: 1000W / 4.5A Protection class: II Speed control: 6-step control Weight: 47 - 77kg Package includes: Tube saw with electric drive One saw blade One bottle of saw blade lubricating oil

Request for a quote

ORBITEC GMBH

Germany

The 5th generation of our reliable, tried-and-tested standard controller. Can be connected to Tetrix 200 or Tetrix 351. — With special software only for RBK tube-to tubesheet weld heads — 5.7" display — Extremely simple multilingual user guidance thanks to programming support — Monitoring of gas and water cooling — Option of welding in up to SIX sectors, in continuous or step travel mode — Individual modification of the calculated program parameters, also using current percentage button — Graphic display of the welding progress — Real-time monitoring of the welding parameters ... Package includes: — Controller — Power cable — Controller / power source interface cable — USB stick — 2 pieces tungsten boxes — Pen with touch screen function and LED light Optional: — Cool 50 or EVO Cool cooling unit — AVC upgrade kit — Docutronic 2.2 software for documentation — Orbicontrol 3 remote control — Spare paper rolls, spare ribbon cartridges

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

BDA CONNECTIVITY GMBH

Germany

Distribution and line cables are used in broadband communication networks. Longitudinally welded high-purity copper tubes ensure optimum immunity to interference radiation as well as high stability. Made in Germany quality. They are used for signal transmission between head-end station and house connection. They can also be used in public broadband communication networks or underground installation.

Request for a quote

ALPHA LASER GMBH

Germany

AL-SWS - the multifunctional laser workstation with variable table inserts for sensor production With this flexible laser machine you can effortlessly weld and cut even the smallest workpieces up to 12 mm in diameter, either automatically or manually. This laser system is mainly used in sensor production and in medical technology, for example for the production of jacket-insulated cables, sensors, resistance thermometers and thermocouples. Depending on the desired application, five different, interchangeable table inserts are available. These can be changed in a matter of seconds so that you can easily switch between the following welding or cutting tasks: Contact welding Circular welding Micro welding To cut Mantle welding under mechanical pressure

Request for a quote

ABS SAFETY GMBH

Germany

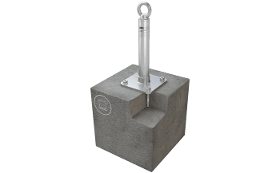

This stainless steel anchorage point, which can be used by one individual for abseiling purposes, comes with an extra-thick base plate (150 x 150 mm) and a welded-on supporting tube (Ø 42 mm). It is simply embedded in concrete using the 4 drive-in dowels supplied. EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Designed for C20/25 concrete ≥ 120 mm For installation depths ≥ 70 mm Secures up to 3 individuals Suitable for usage by 1 individual for recurrent abseiling work Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which comes with a base plate (150 x 150 mm), has been approved by the German Institute for Construction Technology ("DIBt"). It is installed on a steel structure and countered on the other side. The welded-on supporting tube (Ø 42 mm) easily withstands the pre-tensioning stress to which it is subjected when used in a lifeline system. Our standard package includes a set of installation materials. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Incl.stainless steel installation set

Request for a quoteResults for

Welded tubes - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Cables & Networks (9)

- Welding, soldering and brazing - equipment and supplies (6)

- Laser - cutting and welding machines (2)

- Forming - steels and metals (2)

- Hoses, pipes and tubes - plastic (2)

- Pipes and tubes, steel (1)

- Pipes and tubes, aluminium (1)

- Connectors, plumbing (1)

- Containers, metal (1)

- Custom packaging (1)

- Goods handling systems, continuous (1)

- Metal straightening machines (1)

- Power saws, portable (1)

- Rolling machines (1)

- Safety vaults (1)

- Scaffolding and ladders (1)

- Signs and signalling panels and boards (1)

- Vacuum cleaners - industrial (1)

- Wine-making - machinery, equipment and plants (1)