- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welded parts

Results for

Welded parts - Import export

WILH. KÄMPER GMBH U. CO KG

Germany

We employ welding robots to join complex metal wire parts made of steel or aluminium to form an assembly. This in turn leads to complex bent wire components for the automotive industry, such as brackets for cushioning frames, and eyelet fastenings.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used for mechanical .

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a welded pipe made of stainless steel,mainly used for connect both of the two sides od the products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision machinery parts,Brass turning and milling.Electric zinc surface treatment

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

They are the pipe made by stainless steel 304,mainly use for the connector.

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

FÖHRENBACH GMBH

Germany

With high demands on accuracy and dynamics, the base frame in welded construction or hard stone is also a possible and reasonable part of the scope of supply. Here, all axes are specified, assembled, aligned, measured, tested and recorded - according to desired specifications. By means of hard stone, the required accuracies can be achieved. Hard stone offers all the characteristics required - ranging from a small coefficient of expansion, high abrasion resistance, optimum vibration damping, absence of unwanted residual stresses up to the necessary accuracies regarding flatness, parallelisms and angularity.

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

Our steel construction is certified according to the current standards DIN EN 1090-2 and DIN EN 3834-2. We manufacture welded parts, welded constructions and welded assemblies up to execution class 3 (EXC3). Steel construction components such as: - Assembly devices for aircraft or automobile construction - Machine frames for compressor construction - Welded frames such as track systems and transfer tables - High-precision vacuum clamping plates for high-pressure presses - Complete rudder systems We produce both: individual components and small series. Do you have any questions about our techniques, capacities or prices? Contact us, we will be happy to give you direct information.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

ROTAWELD is our platform to cover a wide range of applications requiring circumferential seam welding. The precision servomotor rotation axis combined with our advanced control system form the basis for the production of accurate and repeatable circumferential seam welds. Machine sizes, part holders, welding equipment, torch holders and any additional positional axes are designed specific to the customer and their products.

Request for a quote

SCHNELLDORFER MASCHINENBAU GMBH

Germany

Schnelldorfer CORNERWELD seam welding machines have been designed to weld sheet metal plates in a 90° joint. The precision clamping system with inert gas coverage and advanced OEM control package precisely controls the welding sequence and weld parameters, resulting in the perfect weld for your corners. CORNERWELD applications include welded corners for food, medical equipment, HVAC drip pans, electrical enclosures, and laboratory furniture. Complex inward and outward flanges can be accommodated with custom made tooling pieces. A wide range of materials can be welded, including Stainless Steel, Carbon Steel and Aluminium. Complete welded parts do not require any costly grinding, polishing or blending thus greatly saving on manufacturing costs.

Request for a quote

LACERS GMBH

Germany

ECO-Sealer-300 with cutting device The ECO-Sealer is an economically optimal solution for the welding/sealing of smaller runs, and they are also very well suited as a starting point for the manual sealing of your packaging. The ECO sealers are ideal for sealing PE (polyethylene) and PP (polypropylene) films. The impulse welders of the ECO series do not require any warm-up time, they are ready for use immediately after activation. They have an adjustable timer with indicator light. This will help you to create the optimal welding seam / sealing seam for your film. This model is also equipped with a cutting device. At a glance: Impulse welder with cutting device suitable for welding PE and PP foils Version with time switch different weld lengths possible Spare parts/accessories available suitable for welding max. 2 x 150µ Weld length: 300 mm Weld width: 2 mm<

Request for a quote

LACERS GMBH

Germany

Impulse sealing device Eco-Sealer-200 Film sealing devices / impulse sealing devices of the Eco-Sealer series: The ECO-Sealer series is a very economical solution for sealing / sealing smaller runs. They are also suitable as an entry point for manually sealing your packaging. Our ECO sealers are ideal for sealing / sealing PE (polyethylene) and PP (polypropylene) films. They do not require any warm-up time, they are ready to use immediately after activation. In addition, they have an adjustable timer with indicator light, which helps you to create the optimal weld seam / sealed seam for your film. At a glance: impulse welder suitable for welding PE and PP foils Version with time switch different weld lengths possible Spare parts/accessories available suitable for welding max. 2 x 150µ Weld length: 200 mm - Weld width: 2 mm

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This low cost tension/compression load cell is an especially robust component, which can be easily integrated in a girder assembly between two cables or chains for measuring force. The standard model comes with internal thread, allowing any adapter parts, for instance eye brackets, to be fitted in the axis of symmetry. Alternatively, the optionally available adapters with external thread can be used for quick and easy screw-fitting into a threaded hole made for the purpose. The radial connection cable is extremely flexible and designed for a wide range of motion. In order to achieve the greatest possible stability for such a small sensor, making it suitable not only for the laboratory but also for industrial use, all parts have been welded together including the cable guide bush in the sensor housing. burster TEDS with an electronic sensor datasheet or standardization of the output signal in the sensor connecting cable are offered as options

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Customized Solution Component supply and emissions over hand-operated turret Application Quality assurance in the electronics industry. Batch testing; Test equipment for testing and optimization of weld two part housings of SMD components. Batch testing; Test device for checking and optimizing the welded connection on two-part housings of SMD components. Test device for small SMD parts Documentation of the maximum torque achieved and the tear-off angle. Documentation of the maximum achieved torque and angle of demolition.

Request for a quote

TEC ARTEC GMBH

Germany

Our patented desuperheater TECtemp HT R ring cooler is designed with a three-part structure without moving parts and without weld seams in the steam lances. These are arranged in a ring shape depending on the steam pipe nominal diameter. For example. 40 individually controlled nozzles can be used in this way. Homogeneous distribution of the injection water makes short evaporation sections and minimal load of the steam pipe possible. The geometry of the steam lances acts like a venturi nozzle in the steam pipe which results in clearly reduced loss of pressure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MECHASYS GMBH

Germany

Laser welding is a very gentle welding technique, as the heat input takes place in a locally very limited area. In this way, it is possible to reliably connect critical components with one another in a materially bonded manner, without the parts annealing. With laser welding, the two welding partners are joined together with as few gaps as possible in order to then weld them together (e.g. press-fit zones such as EloPin® puzzled at any feed or distance). The background to this is that no additional material is generally used in laser welding. Exception for build-up welding or repair welding of e.g. broken tool parts such as punches or cutting plates or injection molding tools for abrasive plastics with glass fiber filling. Materials - almost all metals: e.g. • non-ferrous metals (Cu, CuSn0.15, CuSn6, CuNiSi, ...), • titanium, • steel, stainless steel (1.4301, 1.4404, ...), • spring steel (1.4310), • electrical steel (M235, M270, NO20, NO30, ...), …

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Two-part-weld-construction for welding or anchor bolt fastening ▪ Covering all standard metric and imperial diameters between 220 mm and 1016 mm / 8.66 inch and 40.00 inch ▪ With either 4 or 5 plastic pads, depending on size and diameter

Request for a quote

MECHASYS GMBH

Germany

Electrical Steel: rotor and stator sheets as full service Due to the growing demand for electrical steel, we have bundled our technological resources and expanded the production of pure sheet metal blanks to complete packages in stator and rotor sheets. We are therefore able to provide you, our customers the service of complete sheet metal stacks baked, laser-welded or punched packaged in the electrical steel sector. Due to our extremely thin cutting gap of just 0.07mm - as much as the diameter of a human hair - we are able to produce the smallest contours. The extreme power density at a max. laser power of 1,000 watts enable electrical sheets based on baked varnish technology with the lowest possible edge zone melting - burr-free. Everything 100% "Made in Germany" in packaged quality - usually tolerance class T7. Usual delivery times are approx. one week for cutted sheets, 2-3 weeks for baking or welding parts. Let’s get in contact for your new e-drive, rotor or stator!

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

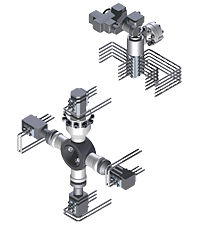

Optimal machine design for 20 kHz applications for which the joining process must be precisely performed by several sonotrodes in a single weld process. The rigid sonotrode support is realized by means of individual alignment modules and allows for accurate positioning even at large weld forces. Contrary to conventional designs, the weld stroke is performed by the anvil. During this stage, the plastic parts to be welded are moved against the stationary sonotrodes. Thus, it is possible to obtain machine cycle times of less than 10 seconds.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Shuttle table machines are characterized by an operating area that is separated from the loading station. The plastic parts to be welded can thus be optimally loaded into the equipment. Thanks to good accessibility, assembly and loading tasks can be easily performed. Can optionally be designed with one or more work stations. Approach of several operating positions is performed by means of a freely programmable linear drive. In this way, weld tasks can be divided into individual process steps. Tool change systems: optionally available.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

With the help of the MULTICELL concept, small multi-head applications can be easily implemented. In general, the plastic parts to be welded are loaded directly below the sonotrodes. A shuttle table can be optionally integrated for improved handling. This modular concept is particularly suitable for 20 kHz applications with sound insulation and can be customized by installation of a large number of accessory options. The compact make-up and high degree of mobility allow for universal application in manufacturing.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The core of this ultrasonic welding machine is the patented pneumatic HMC drive concept. It combines the benefits of pneumatics with the dynamics of an electrical drive and allows for selection of any optional start point for the weld process. The SoftTouch mode protects the sensitive joining area of the plastic parts to be welded during contact of the sonotrode.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

ALPHA LASER GMBH

Germany

The desktop laser welding machine delivers with 50 watts good beam power and is characterized by its uniform, powerful, yet soft welding behaviour. The manual welding laser VL 50 has a very spacious working chamber and allows to weld precious metals such as silver and gold due to its powerful laser behaviour. Longer concentrated work is easily possible thanks to the ergonomically designed housing with the well thought-out arrangement of keyboard, display and joystick. The desktop laser VL 50 is a valued tool in the manufacture and repair of dentures and jewelry, in welding on precision parts, medical technology components and sensors, but also when applying materials to small molds.

Request for a quote

KLN ULTRASCHALL AG

Germany

The LVW series covers smaller applications with machines of approx. 500 mm width and large applications up to a width of 2000 mm, like pallets, bumpers and more. As a principle our standard machines are equipped with an hydraulic lifting table. Depending on the machine size a contact force of up to 70 kN can be applied. This is necessary for large suction pipes made of PA 6.6 GV30 with heavy distortion or very large welding surfaces. Our vibration welders are fitted with our patented CPC system. This kind of regulation which is integrated in the converter stimulates the vibration unit with optimal resonance frequency. A low energy consumption is guaranteed during the friction phase. It is not necessary to enter the frequency parameter in the machine, as it is permanently “optimized”. This, the KLN drive systems are independent from the tool weight. The tool weight is solely limited in height, caused by the mechanical design and the high accelerating powers arising in these systems.

Request for a quote

KLN ULTRASCHALL AG

Germany

For the assembly of plastic parts, which differ in size and condition and would therefore not be suitable for standard machines, we recommend the use of special equipment with several ultrasonic units for ultrasonic welding and processing methods. • Riveting • Welding • spot welding • punching • flanging • cutting • embossing • printing Multi-head systems These machines can also be used to accomplish complex tasks, e.g. the combination of different welding techniques, like spin welding and hotplate welding and for numerous automated processes

Request for a quote

KLN ULTRASCHALL AG

Germany

In our laboratory we have all options to supply you with tests, parts analysis and pre- or small batches productions. Our team of highly skilled experts will assist you, if you have any question about how to design your parts for optimal welding. In our plant in Heppenheim we have the option to do welding tests with all the welding methods we offer in order to give you the maximum reliability for your serial process.

Request for a quoteResults for

Welded parts - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Laser - cutting and welding machines (4)

- Steels and metals - welding and brazing (4)

- Agricultural machines and accessories (2)

- Machinery and equipment, used and reconditioned (2)

- Packing and packaging - machinery and equipment (2)

- Silicones (2)

- SMALL METAL PARTS (1)

- Automation - advisory services (1)

- Automation - systems and equipment (1)

- High-vacuum photo-cells (1)

- Industrial cutting machine tools (1)

- Measurement and control instruments (1)

- Mechanical engineering - custom work (1)

- Plumbing, industrial (1)

- Radiators, engine (1)

- Sensors (1)

- Spraying equipment, agricultural (1)

- Steel (1)

- Storage tanks (1)

- Thermoforming, plastics - machinery (1)