- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flexibility

Results for

Flexibility - Import export

SAMAG MACHINE TOOLS GMBH

Germany

KNOW-HOW & EXPERIENCE, COMMITMENT & IDEAS, RELIABILITY & FLEXIBILITY – SAMAG, MACHINE TOOLS FROM THURINGIA SINCE 1873! WE SEE OURSELVES AS DEVELOPERS AND MANUFACTURERS OF MACHINE CONCEPTS, FROM INDIVIDUAL MACHINES TO TURNKEY LINES. THE FOCUS OF OUR PRODUCTS IS ON MILLING AND DEEP DRILLING TECHNOLOGIES. Separated from the SAMAG Group, we have been independently continuing the tradition of mechanical engineering in Saalfeld / Thuringia as SAMAG Machine Tools GmbH since January 2020. With 140 employees, we draw on the experience of more than 145 years of machine tools for metal cutting. One of our strengths is the high level of technological solution expertise with which we help our customers worldwide achieve sustainable success. As an international machine tool manufacturer, our most important sales markets are the automotive industry, tool and mold making and mechanical engineering.

Request for a quote

EMBRO GMBH

Germany

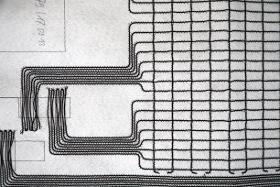

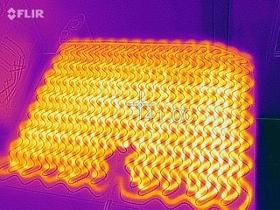

We are using CNC - technology for the laying of thin and insulated heating wires on a variety of carrier materials in order to manufacture all kinds of heating elements. We can work up to sizes of 2 x 2 m, and we can realize medium series (500 - 10.000pcs.) as well as high volume productions (up to 1 million pcs.). All voltages from 3,7V up to 480V are possible. With our elements we can reach temperatures of up to 200°C. Please do not hesitate to contact us!

Request for a quote

KW HYDRAULIK GMBH

Germany

Tools for Laminated and Flexible Bars and Earthground

Request for a quote

EMBRO GMBH

Germany

At Embro, we develop and produce customised, textile-based surface sensors in large dimensions. Applications include: > pressure sensors > impact sensors > detection and monitoring of composites > surface temperature sensors > area sensors for humidity and damage sensing > inductive sensors > capacity sensors

Request for a quote

EMBRO GMBH

Germany

Embro is a German manufacturer of textile-based heating elements and pads. The elements are highly flexible, lightweight, and they are ideal for all kinds of mobile heating solutions such as: > car seat heaters > steering wheel heaters > heating elements for garments (jackets, gloves, ...) Furthermore, our elements are often used in infrared heating panels, too. Do not hesitate to contact us for further information.

Request for a quote

EMBRO GMBH

Germany

When it comes to seat heaters, we at Embro think first and foremost of the textile processors of vehicle seats. Because our textile heating elements are in great demand in the automotive industry. They are easy to process, flexible, and kink-resistant. The heat output is individually adapted to the customer’s requirements in the development process and suitably distributed and laid out on the desired surface (wire laying). With the increasing number of electric vehicles being produced, the demand for further heating solutions for the interior area is also rising. Embro heating mats heat the seats and interior via heating elements in the center and side armrests and trim parts. As a developer or engineer in the automotive sector do you need a specific heating element for a product? We are looking forward to your ideas!

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

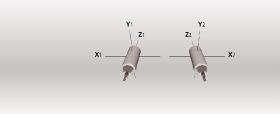

The particularly short distance of the unique DOUBLE BALL SCREW DRIVE from SAMAG increases the rigidity and thus the machining accuracy immensely. Compared to traditional drive concepts, the TFZ concept is up to 27 times stiffer and more precise. Reduction of vibrations on the drilling and milling unit through DOUBLE BALL SCREW DRIVE and POWER TOWER DESIGN, this is how it works: Second ball screw with additional guide and second pivot bearing on the rear rail (V) Upstream double-guided and particularly strong ball screw drive of the X-axis Minimum distance (l) between tool tip (TCP) and front swivel bearing (A) 1-spindle concept guarantees short, stable tools with excellent accessibility to the workpiece and the machining point Generously sized work spindle to achieve maximum performance parameters Stiff milling spindle with additional, patented support Variable steady rest positioning system to increase drilling accuracy with spacer between spindle and steady rests

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

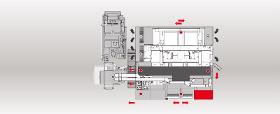

TBM flex – special deep drilling and milling centers – deep drilling and milling in one machine Modular system for drilling and milling For individual part and small series production Peeling and rolling possible Processing of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2006, extensive manufacturer overhaul in 2021 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2006 Extensive manufacturer overhaul 2021 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm KSM rotary union with electronic leakage monitoring Chip conveyor Knoll (scraper belt conveyor in positioning variant along the machine, ejection height 1,200mm)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

SMART STRETCH TECHNOLOGY – INTELLIGENT USE OF SPACE. SMART STRETCH TECHNOLOGY – means flexibility in widening the work area in optimal harmony with your processing workpiece, while maintaining the same, cost-optimized machine size. Variable spindle distances in the X axis within the MFZ 7 Adaptation of the workspace design to the machining workpiece Lower machine investment costs thanks to workspace flexibility Lower additional production costs due to optimal machine installation space Shorter delivery times thanks to modular machine design Ecological, because only as much “machine” is manufactured as is required for your workpiece Higher productivity by increasing the number of spindles with the same working space per spindle in the same machine size Definition of the machine by the workpiece and not by the spindle distance

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-SPINDLER WITH TWO INDEPENDENTLY CORRECTABLE 3D UNITS (X, Y, Z) FOR HIGHEST PRECISION WITH CRITICAL TOLERANCES. COMPARABLE TO TWO 1-SPINDLE MACHINING CENTERS STEREO 3D SETUP – CONSTRUCTIVE DECOUPLING OF THE 2-SPINDLE SYSTEMS. 2-spindle with two independently correctable 3D units (X, Y, Z) Highest precision for critical tolerances Comparable to two 1-spindle machining centers Easy tool setup and lower tool costs New range of workpieces - finish processing of complex components Minimal setup time for new workpieces

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Machining time on 3-spindle solution 97s Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Processing time less than 80s per workpiece possible Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

3 or 4 spindle machining Complete processing on MFZ Processing time less than 55s per workpiece

Request for a quote

RUHLAMAT GMBH

Germany

The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio. The system can be designed to perfectly match your needs: sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R). This flexible solution offers the most economical way to produce RFID inlays for ID documents in large quantities. You get unrivalled real-world throughput: up to 4,050 antennas/hour as antenna embedding machine and up to 2,000 finished RFID inlays/hour as inlay manufacturing line. The WCE2000 is available in virtually unlimited configurations. Wire coil embedding, module pick & place, soldering, and testing are the main features that can be integrated to build a tailor-made solution. Punching, sheet cutting, handling and collation of additional layers, and other features complement the system to a complete inlay manufacturing line. The possibility to combine all of...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RUHLAMAT GMBH

Germany

Advanced customer expectations, strong market dynamics, new security threats, and cost pressure require new levels of efficiency and economy in card personalisation. The Pearl ID delivers the reliability, flexibility, security, and profitability to meet your specific needs in centralised card personalisation. With a throughput of up to 3,300 cards/hour, it is the ideal system for the high-speed production of ID cards, driver’s licences, health cards, payment cards, commercial cards, and other smart cards. You can choose from a comprehensive range of technologies, depending upon your personalisation requirements, production volumes, and growth objectives. The Pearl ID is supplied as tailor-made solution with automated inline quality control, and enables to combine laser engraving, industrial inkjet printing, security lamination, smart card encoding, and other technologies. Different laser systems for marking and optical personalisation can be integrated, with up to six laser heads...

Request for a quoteResults for

Flexibility - Import exportNumber of results

19 ProductsCountries

Company type