- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- engineering work

Results for

Engineering work - Import export

INOX VERTRIEBS GMBH

Germany

INOX specializes in contract filling of aqueous, solvent-based and pasty mixtures. Whether commissioned, ready-made or filling - we are the right partner for your filling contract production! In doing so, we can provide comprehensive service, starting with the chemical and technical approaches, over sampling, laboratory work, analytics and engineering – all the way to the creation of product and safety data sheets.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

KNOW-HOW & EXPERIENCE, COMMITMENT & IDEAS, RELIABILITY & FLEXIBILITY – SAMAG, MACHINE TOOLS FROM THURINGIA SINCE 1873! WE SEE OURSELVES AS DEVELOPERS AND MANUFACTURERS OF MACHINE CONCEPTS, FROM INDIVIDUAL MACHINES TO TURNKEY LINES. THE FOCUS OF OUR PRODUCTS IS ON MILLING AND DEEP DRILLING TECHNOLOGIES. Separated from the SAMAG Group, we have been independently continuing the tradition of mechanical engineering in Saalfeld / Thuringia as SAMAG Machine Tools GmbH since January 2020. With 140 employees, we draw on the experience of more than 145 years of machine tools for metal cutting. One of our strengths is the high level of technological solution expertise with which we help our customers worldwide achieve sustainable success. As an international machine tool manufacturer, our most important sales markets are the automotive industry, tool and mold making and mechanical engineering.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PROCESS-RELIABLE SOLUTIONS FOR HIGH VOLUMES – EFFICIENT PRODUCTION WITH MINIMAL UNIT COSTS. The automotive industry is the ultimate challenge with its range of parts and performance indicators. Only innovative machine concepts are solutions that ensure efficiency in the process. Companies from the vehicle and supplier industries worldwide therefore successfully use SAMAG machining centers and production machines, including turnkey solutions. High precision, reliability, automation and cost optimization are among the key automotive requirements.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CLAMPING DEVICES FROM THE EXPERTS. SAMAG OFFERS PROCESS-OPTIMIZED SOLUTIONS AND A COMPLETE ALL-ROUND SERVICE WHEN IT COMES TO DEVICE CONSTRUCTION. Complete machining of workpieces begins with the right clamping concept. Our engineers develop innovative solutions and clamping devices at the highest technical level. Processing complicated workpieces in efficient cycle times requires process-optimized clamping. We deliver technological solutions with longevity and all-round service. The workpieces are aligned, fixed and clamped hydraulically, pneumatically or mechanically. If several parts are processed at the same time, depending on the number of motor spindles, high-precision fixing, positioning and clamping of the parts is necessary. This is only possible with automated tensioning (e.g. hydraulic) and precise alignment of the devices.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Robust, long-lasting machine for individual part and small series production Very good accessibility to the processing unit and to the workpiece clamping Crane loading possible Up to 3 mobile tool rests Service and maintenance-optimized accessibility to all machine components Crane hook machine, therefore short set-up times OUR TBM mono IS THE SPECIALIST FOR INDIVIDUAL PARTS AND SMALL SERIES. SPECIAL FEATURES: VERY SMALL DRILLING DIAMETERS WITH A LARGE DRILLING DEPTH AT THE SAME TIME

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

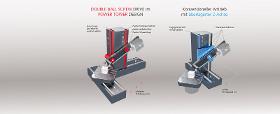

The particularly short distance of the unique DOUBLE BALL SCREW DRIVE from SAMAG increases the rigidity and thus the machining accuracy immensely. Compared to traditional drive concepts, the TFZ concept is up to 27 times stiffer and more precise. Reduction of vibrations on the drilling and milling unit through DOUBLE BALL SCREW DRIVE and POWER TOWER DESIGN, this is how it works: Second ball screw with additional guide and second pivot bearing on the rear rail (V) Upstream double-guided and particularly strong ball screw drive of the X-axis Minimum distance (l) between tool tip (TCP) and front swivel bearing (A) 1-spindle concept guarantees short, stable tools with excellent accessibility to the workpiece and the machining point Generously sized work spindle to achieve maximum performance parameters Stiff milling spindle with additional, patented support Variable steady rest positioning system to increase drilling accuracy with spacer between spindle and steady rests

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

QUICK CHECK GUN DRILL Eight basic cycles, based on experience, are included in the scope of delivery of the machine and guarantee professional processing of the workpiece. Specific groups for cross drilling cycles are available as an option. This makes workshop programming and programming of crossing holes easier by adapting the feed when hitting the cross hole. This increases the tool life significantly.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

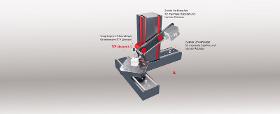

“The deflection (∆) of the tool tip (TCP) due to the machining force (F) depends to the third power ( l 3 ) of the length ( l ) of the distance TCP to the front bearing axis (A), in relation to the bending stiffness (E · I) “ Or: the shorter l , the smaller ∆ and the higher the precision

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

STABILITY AND HIGHEST PRECISION COME BY APPROXIMATE. THE PERFECTLY THOUGHTFUL AXIS CONCEPT IN THE POWER TOWER DESIGN ALLOWS MINIMAL TCP DISTANCE AND MAXIMUM MACHINE STIFFNESS. The POWER TOWER DESIGN impresses with its compact design and extreme rigidity. All components in the force flow are statically and dynamically optimized down to the last detail, thus ensuring perfect work results. The clear separation of all linear axes guarantees long-term dimensional accuracy of all axis drives and sustainably prevents tolerances from overlapping and thereby increasing. Thanks to the large footprint of the Y-tower and the unique DOUBLE BALL SCREW DRIVE, we always achieve optimal support for the drill beam in the TFZ and at the same time an extremely short distance between the swivel bearing and the tool center point (TCP distance), for maximum rigidity with large transverse forces.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

TBM flex – special deep drilling and milling centers – deep drilling and milling in one machine Modular system for drilling and milling For individual part and small series production Peeling and rolling possible Processing of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

THE MULTI-SPINDLE SHAFT DRILLING MACHINES OF THE TBM roto series ARE DESIGNED FOR PERMANENT PRODUCTION USE. THEY ARE PARTICULARLY DURABLE, EXTREMELY ROBUST AND GUARANTEE THE HIGHEST PRECISION: 24/7/365! TBM roto – shaft drilling machine for production For machining rotationally symmetrical workpieces such as gear shafts, camshafts, steering rods, common rails, standard parts... Customer-specific solutions, automation, handling, workpiece clamping, workpiece cleaning… Long-lasting machines for parts with the highest precision Additional units, features or modules available Optimized accessibility to all components for maintenance and service

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

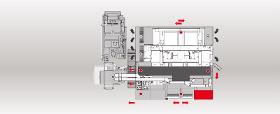

used horizontal machining center – year of construction: 2007-2008 Product name: MFZ 2-3 Update Used 3-spindle horizontal 4-axis machining center Year of manufacture: 2007-2008 Painted in RAL1002 (sand yellow) or red-white Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (per machine without coolant system and accessories) X-axis travel: 300 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z axis 60,000 mm/min 3 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) Knoll KSS system with paper belt filter and magnetic separator Flush gun Complete enclosure Tool storage (3 x 30 tools)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2006, extensive manufacturer overhaul in 2021 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2006 Extensive manufacturer overhaul 2021 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm KSM rotary union with electronic leakage monitoring Chip conveyor Knoll (scraper belt conveyor in positioning variant along the machine, ejection height 1,200mm)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2008 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2008 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Spindle distance 450mm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) High-quality Knoll KSS system with fine filtration Flush gun Complete enclosure Tool storage (2 x 50 tools) Operating voltage 400V 3N ~ Control voltage 24V DC Connection value machine approx. 72 KVA Compressed air connection 6 bar

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used, partially overhauled three-spindle, horizontal machining center Product name: MFZ 2-3 Update Machine number 53152 Used 3-spindle horizontal 4-axis machining center Year of construction: 2009 The machine produced until October 2020 Sinumerik 840D Powerline control X-axis travel: 300 mm Y-axis travel: 500 mm Z axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z-axis 60000mm/min 3 motor milling spindles GMN, version with HSK63 tool holder Drive power (S1 / S6) 28 KW (constant) Torque (S1 / S6) 63/83 Nm Maximum speed 16,000 rpm Chip conveyor Knoll (scraper belt conveyor in the setting across the machine) Knoll coolant system with paper belt filter Flushing gun • Complete housing Tool storage (3 x 30 tools) Operating voltage 400V 3N ~ Control voltage 24V DC

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4 SIZES AND LOTS OF POSSIBILITIES! THE SFZ SERIES ESPECIALLY SCORES WITH STRONG PERFORMANCE. Starting from the four basic models of the SFZ series; We offer modular equipment variants, depending on performance requirements. Completely in the spirit of FIT 2 TASK. In order to guarantee individual performance, the SFZ machines are equipped with the latest generation of Heidenhain iTNC640 controls as standard. SIEMENS 840D SL is optionally available as an alternative, depending on your requirements.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SAMAG MACHINE TOOLS GMBH

Germany

SMART STRETCH TECHNOLOGY – INTELLIGENT USE OF SPACE. SMART STRETCH TECHNOLOGY – means flexibility in widening the work area in optimal harmony with your processing workpiece, while maintaining the same, cost-optimized machine size. Variable spindle distances in the X axis within the MFZ 7 Adaptation of the workspace design to the machining workpiece Lower machine investment costs thanks to workspace flexibility Lower additional production costs due to optimal machine installation space Shorter delivery times thanks to modular machine design Ecological, because only as much “machine” is manufactured as is required for your workpiece Higher productivity by increasing the number of spindles with the same working space per spindle in the same machine size Definition of the machine by the workpiece and not by the spindle distance

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

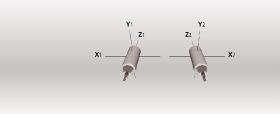

2-SPINDLER WITH TWO INDEPENDENTLY CORRECTABLE 3D UNITS (X, Y, Z) FOR HIGHEST PRECISION WITH CRITICAL TOLERANCES. COMPARABLE TO TWO 1-SPINDLE MACHINING CENTERS STEREO 3D SETUP – CONSTRUCTIVE DECOUPLING OF THE 2-SPINDLE SYSTEMS. 2-spindle with two independently correctable 3D units (X, Y, Z) Highest precision for critical tolerances Comparable to two 1-spindle machining centers Easy tool setup and lower tool costs New range of workpieces - finish processing of complex components Minimal setup time for new workpieces

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

The frame construction concept offers reliable stability thanks to its closed design. The power transmission through the axis movements in the working area does not cause any deformation of the frame. This extremely stable solution is a prerequisite for the high-precision machining of your workpieces and guarantees consistently high process quality. The new generation of the MFZ is also built on the solid machine bed with Hydropol ® filling. The specially developed composite material improves the stability of machine tool beds. Hydropol ® makes a further step possible in terms of the interaction between energy efficiency and high productivity.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

OUR MFZ SERIES CANNOT SHAKE ANYTHING SO EASILY. A SOLID FRAME CAST WITH HYDROPOL ® AND THE CLOSED CONSTRUCTION GUARANTEE THE HIGHEST PRECISION THROUGH BEST VIBRATION DAMPING AND TEMPERATURE STABILITY. The new generation of the MFZ is also built on the solid machine bed with Hydropol ® filling. The specially developed composite material improves the stability of machine tool beds. Hydropol ® makes a further step possible in terms of the interaction between energy efficiency and high productivity. ROCK SOLID DESIGN – THE ADVANTAGES OF A ROCK SOLID MACHINE BED OVER STEEL AND CAST CAST FRAME: Closed construction – analyzed and optimized according to FEM Optimal power flow

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

SIMPLY ROTATE THE 3D UNIT BY 90° AND THE MASS THAT HAS TO BE MOVED IS ONLY HALF AS BIG! ZERO GRAVITY DRIVE – OR TURN WITH MASS. Through the rotation and the resulting reduction of the mass to be moved - by around half - we can use the ZERO GRAVITY DRIVE to achieve an incomparably efficient, dynamic and stable type of spindle movement in all three spatial axes. This new kinematic concept is unique in multi-spindle machining centers and enables maximum efficiency and absolute precision on the one hand and maximum utilization and extreme cost-effectiveness on the other.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with a 4-part clamping device Editing the OP 20 after the turning process Piece time less than 90s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles Clamping device with 6 or 8 workpieces Processing the ends and connections on MFZ Processing of deep hole drilling 4-6 spindling on SAMAG shaft drilling machines

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles in one clamping Machining time on 3-spindle solution 97s Right and left workpieces are produced in the same machine

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution with HSK-A100 on MFZ Machining of the free cut with 4 spindles possible OP 10 and OP 20 are processed in one machine Unit times less than 50s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution for pre-processing 2-spindle solution for fine boring with independent X, Y and Z axes Cycle times less than 30s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles OP 10 and OP 20 are processed in one machine Complete processing in 67s

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quoteResults for

Engineering work - Import exportNumber of results

38 ProductsCountries

Company type