- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatics

Results for

Automatics - Import export

INOX VERTRIEBS GMBH

Germany

INOX Dexron II INOX Dexron III INOX ATF X6 INOX ATF X7

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX automatic transmission protection reduces friction and prolongs service life of seals and sealing rings. This results in a smoother switching of gears. INOX automatic gearbox protection delays the renewed deposition of resins and similar soilings.

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX automatic transmission cleaner is used to clean all vehicles with automatic transmission. Any soiling will be dissolved completely. It has a noise-reducing effect and ensures that the gearbox runs safely and smoothly. The gear switching process itself will be optimized.

Request for a quote

RUHLAMAT GMBH

Germany

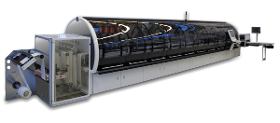

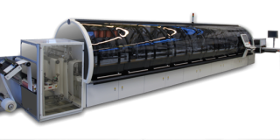

The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio. The system can be designed to perfectly match your needs: sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R). This flexible solution offers the most economical way to produce RFID inlays for ID documents in large quantities. You get unrivalled real-world throughput: up to 4,050 antennas/hour as antenna embedding machine and up to 2,000 finished RFID inlays/hour as inlay manufacturing line. The WCE2000 is available in virtually unlimited configurations. Wire coil embedding, module pick & place, soldering, and testing are the main features that can be integrated to build a tailor-made solution. Punching, sheet cutting, handling and collation of additional layers, and other features complement the system to a complete inlay manufacturing line. The possibility to combine all of...

Request for a quote

RUHLAMAT GMBH

Germany

The WCE2000 is our fastest and most productive high-volume system for wire embedding and RFID inlay production. You get unrivalled real-world throughput with up to 4,050 antennas per hour as antenna embedding machine and up to 2,000 finished RFID inlays per hour as inlay manufacturing line. This modular and flexible system allows processing of various substrates and provides sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R) handling. WCE700 - Semi-Automatic Production System The very economical WCE700 can handle both small jobs and high-volume runs easily with up to 1,600 inlay sheets per hour. The system is capable to work with a wide range of substrates and can also be used for only antenna embedding, with unrivalled speed, accuracy and the quality of antennas that it produces. WCE150 - Laboratory System You are looking for a convenient solution for laboratory usage to produce prototypes or low-volume jobs? The affordably priced WCE150 is designed to produce...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OFS ONLINE FLUID SENSORIC GMBH

Germany

Softcontrol RM monitors the soft water produced by the softener for increased hardness concentrations and also triggers the regeneration of the softener in terms of quality. The monitoring of variable water hardness limit values from 1 ppm to 18 ppm takes place as well as the quality-controlled triggering of the regeneration of two columns of the softener. A continuous measurement takes place as long as water flows. Indicators are dispensed with and low-maintenance ion-selective sensors are used instead. The device has self-monitoring so that, in the event of service, information is provided automatically for less maintenance. The measured values are output on the display, via a 4 to 20 mA current loop and via a LAN data interface with Modbus / TCP. The data is also saved in the electronic operating log (USB stick). Installation and parameterization is easy to carry out on the device.

Request for a quote

OFS ONLINE FLUID SENSORIC GMBH

Germany

Water hardness is influenced by changes in raw water, flow, pressure and bypass valve. The continuous monitoring of the water hardness behind a blending system with Softcontrol V-UE is therefore of great importance. The device monitors the limit value of the water hardness of blended water on a water softener approx. Every 30 seconds. The limit value can be parameterized in the range between 18 ppm and 360 ppm. The data is shown on the display, saved on the USB stick and output via a 4 to 20 mA current loop. The integrated ion-selective sensor works without the use of an indicator. Installation is simple, the limit value can be parameterized and the sensor, as the only common spare part, reports that it is easy to replace if necessary.

Request for a quote

OFS ONLINE FLUID SENSORIC GMBH

Germany

Softcontrol Carbonate is used to monitor the decarbonised water after a decarbonisation system. If the parameterizable limit value is exceeded in the range from 9 ppm to 90 ppm, an alarm is triggered. the device measures approx. 2 times per minute with the help of the integrated ion-selective sensor. Thanks to its continuous analysis, it offers protection for downstream systems and their processes. In addition, the device system monitors itself and automatically indicates the simple change of the sensor without additional tools. The measured values are shown on the display and output via the parameterizable 4 to 20 mA current loop.

Request for a quote

OFS ONLINE FLUID SENSORIC GMBH

Germany

Softcontrol Data offers individual setting options and a clear presentation of the information on the display. The device is a comprehensive alarm system for upstream water softening systems with high safety requirements for the soft water quality. The limit values for the water hardness can be set in the range from 1 ppm to 18 ppm based on the input water hardness. The measurement data and service messages are automatically saved in the readable, integrated USB stick and transmitted via a current loop and LAN interface with MODBUS / TCP. For increased operational and process reliability with the best user friendliness. A continuous measurement takes place approx. 2 times per minute as long as water is flowing. indicators are not used and an ion-selective sensor is used instead. This monitors itself and indicates the required exchange itself. This is usually the only maintenance on the device that has to be carried out around twice a year.

Request for a quote

OFS ONLINE FLUID SENSORIC GMBH

Germany

The measuring device Softcontrol Smart for monitoring the water hardness is small, compact and particularly simple for more security of your processes and without constant maintenance of the monitoring device. This compact solution can be installed on any water softener regardless of type and size. The hardness limit is continuously and reliably checked. If the limit value is exceeded, a brine alarm or service is required, an alarm is issued via potential-free contacts. The installation is very simple and does not require any parameterization. No indicators are required as an ion-selective sensor which is used for the measurement. This electrode is also the regular spare part, which can be easily changed without tools. Further maintenance work is generally not required. Process reliability is improved thanks to the integrated self-monitoring.

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

The new AlphaOne - the combination of precision and flexibility. With the compact and simultaneously highly precise measuring device for cross section measurements of cables and hoses, you receive new possibilities in your quality assurance process. Area of Application ● Highly precise measuring device for cross section measurements of cables and hoses ● Measuring device especially designed for use in a production line Device details ● Specific object size - depending on the production line ● Quick and very easy measurement ● Little training required ● Measuring software VELOX included ● Compatible with all database software of the VCP family ● Various ext.CAQ software are connectable ● Low operator influence due to fixed focusing as well as preset illumination ● Robust design and simple, user-friendly operation ● Shock and vibration resistant due to an optimised sensor arrangement and balanced weight distribution ● Various operator level settings

Request for a quote

IIM AG MEASUREMENT + ENGINEERING

Germany

The perfect machine to quickly and automatically return the winding material remaining on the spools to the recycling process. The spools do not suffer any damage and can therefore be used over a long period of time. Device details: ▪ Enables up to 24 braiding spools to be unwound at the same time ▪ Appropriate spools: ▫ Diameter of mandrel 23 mm (standard version) ▫ Spool outer diameter up to 100 mm ▫ Other spools with different inner and outer diameters possible ▪ Suitable for different winding materials, e.g. metal wire, plastic, natural, glass and carbon fibres

Request for a quoteResults for

Automatics - Import exportNumber of results

13 ProductsCountries

Company type