- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- weighing machines

Results for

Weighing machines - Import export

CUPASO DEUTSCHLAND GMBH

Germany

Features: - Two modes can be selected, either High Precision or High Speed - Scale amplitude can be adjusted manually or automatically to ensure maximum throughput and accuracy - Waterproof and dustproof design for easy maintenance - Multilingual control panel: German, French, English, Spanish... - Weighing accuracy: 1 to 5 g - Speed: Max. 70 weighings per minute - Capacity per discharge: 100 - 3000 g

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Features: - Programme recovery function - All hoppers can be opened to facilitate cleaning - The weighing hopper can be preset in an offset position to avoid jamming - Multilingual control panel: English, French, German, Spanish... - Discharge capacity: 800 - 1500 g - Weighing accuracy: 0.5 - 2 g - Speed: Max. 45 weighings / minute

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Tecnimodern automatic counting and weighing machines allow you to count and weigh different parts such as screws, nuts, washers, parts (metal or plastic), dowels, small hardware, confectionery. Thanks to the simple set-up, you can switch from one type of part to another in a few seconds. The frame counting cell, controlled by the PLC and equipped with a filter, counts only parts and no waste. Weighing is performed by a calibrated scale. The control panel allows very easy access to the settings and displays errors in plain text.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

This range of linear checkweighers is designed to fit all types of packaging machines, tray conveyors or simply for manual bag filling. These scales are compatible with a wide range of products: - Sweets - Cakes - Chocolate - Coffee - Rice - Detergent - Nuts and bolts - Confetti ... All parts that come into contact with the product are made of food-grade stainless steel and are easily removable.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

As an angle sensor that is both accurate and economical, this rotary potentiometer is suitable for all types of analog angle measurement up to 350°. Typical fields of application include: —Position feedback in servo-systems —Pendulum weighing machines —Cam and butterfly flap positions —Jockey roller controllers —Measuring the tension of threads and tape —Trigonometric measurements at joints The heart of the potentiometric angular displacement sensors is an extremely precise, low-wear resistor track made of plastic. Due to its high resistance to abrasion, the sensors are particularly suitable for measurements for the purpose of quality assurance in ongoing production, where a long service life and large numbers of rotations are required. The potentiometric angular displacement sensor uses a multi-finger slider system with precious metal contacts. This ensures good contact even when moving at high speed and in the presence of vibrations.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 52 is intended for the simultaneous 5-axis machining of workpieces weighing up to 2000 kg - with unbeatable accuracy and precision. Parameters that always represent a challenge for the machine dynamics. HERMLE has overcome these challenges by developing and designing a precise and high-performance machining centre. The C 52 is the successor of the extremely successful C 50. The C 52 machining centre: A flexible all-rounder with a large working area and minimum footprint. The tool magazine of the C 52 is also integrated and can be extended to 325 pockets using an additional magazine. The C 52 sets new standards: These standards are particularly valued in demanding applications, for instance in the medical, aerospace and automotive industries. In short: wherever the highest precision and maximum efficiency are required. Milling and turning in one clamping - the MT series with the model C 52 U MT dynamic.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Preparation unit tanks for first and second phase Storage tank equipped with flowmeter system Homogenizer Sanitary centrifugal pump Mechanical filter Filter platform collector Pipes and fittings All joints are tic and orbital welded, polished and treated Stainless steel Teflon check valves, Pipe tri clamp joints. The production capacity varies depending on the type of products Gear pump cycle of the feeding device can speed up product forming and rapid discharge Semiautomatic weigh filling machine for gallons. Monoblock filling and capping machines feeding and collecting tables HMI and SCADA with touch screen system. Available certification up on your request UL, CE, GMP, FDA, ASME.

Request for a quote

WHITE STEEL GMBH

Germany

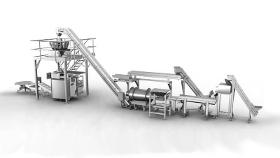

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Manual feeding system , automated feeding system is also available up to your request Drum blender with paddles and gravity positioning flow system Fast and automated powder storage release system . HMI, PLC with SCADA system integrated for easy workflow Tunnel conveyor transfer system for quick and easy powder transfer Automatic weighing tower Electropneumatic Automatic weighing cells Vertical powder packaging machine Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Cheese chopping machine SCADA and HMI with a touch screen system Hardened stainless steel slicer and 3d chopping system Cups feeder system Antistick powder processing system Vertical conveyor transfer system Automatic suppress distribution system Electro pneumatic weighing cells 3 levels weighing cells Weighing tower Packaging machine Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer Vortex™ It is suitable for any industry where different recipes need to be mixed in quick succession, resulting in frequent mixer cleaning. As the transport container and mixer head are separate units, products can be conveyed to the next processing station without loss of time. The design of the MIXACO Vortex™ mixer, which was robust from the outset, is continuously being improved and updated. The system and its individual components are also configured for multi-level operation, with corresponding connectors to allow dust-free, airtight discharging of the transport container directly into extrusion, kneading, weighing and bagging machines. The MIXACO Vortex™ is more than simply a classic among container mixers; it also offers modern technology with numerous advantages for your in-house material logistics and work processes.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Compact, flexible, fixmounted or extendible, and perfectly maintainable. The Motion06 CheckIn, with the CheckIn Premium, is the highest standard of design and functionality. The CheckIn Easy, based loosely on the motto, “less is more”, completes the CheckIn department at the airport base. The whole family of CheckIn is characterised by optimal operability by the operator and optimal accessibility for the passenger. The CheckIn is the passenger’s point of contact with the entire flight baggage system. Whether it be the fixmounted or the extendible version, simple and fast accessibility for maintenance and cleaning work is guaranteed with both. Depending on the feed rate, you can choose from onebelt, twobelt and threebelt systems. The position of the weighing machine also depends on the customer‘s requirements.

Request for a quoteResults for

Weighing machines - Import exportNumber of results

12 ProductsCountries

Company type