- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- weighing load cells

Results for

Weighing load cells - Import export

MINEBEA INTEC GMBH

Germany

Ideal for installation in platform scales and integration into machines: with the BCL-A single point load cell, you rely on proven quality from a leading manufacturer of industrial weighing technology. Suitable for load ranges from 300 g to 4.5 kg and a platform size of up to 300 mm × 300 mm.

Request for a quote

MINEBEA INTEC GMBH

Germany

The MP 55 Platform Weigh Cell is made completely from stainless steel, is available in a load range from 11 kg to 200 kg and platform sizes up to 600 mm x 600 mm. It is specially designed for integration into beltweighers, counting scales and checkweighers. Protection class IP68, IP69K Full stainless steel construction Hermetically welded seal (IP68, IP69K) Platform size up to 600 mm x 600 mm Approved to OIML R60 Ex-Version available (MP55/...E) High Input Impedance Integrated Mounting spacer

Request for a quote

MINEBEA INTEC GMBH

Germany

The PR 6251 fill-level sensor is specially designed for basic weighing of silos and horizontal tanks. It meets all requirements for years of trouble-free operation without adjustment. For use in EX zones 1, 2, 20, 21, 22 and DIV 1. Ultra-flat load cell for low precision tank weighing as alternative to level sensors Load cell capacity range from 500 kg to 16 t Accuracy class: L (0.5 %) Corresponding mounting kit: PR 6051

Request for a quote

MINEBEA INTEC GMBH

Germany

The load cell PR 6212 is a state-of-the-art product. This corrosion resistant load cell has a compact design and also features high heat resistance. Its long product lifetime minimises downtime and ensures safer and more reliable processes in the chemical and steel industry. Compact design ensuring a low system height Maximum corrosion resistance High-temperature version available for up to 180 ˚C Load cell capacity range from 500 kg to 10 t Accuracy class: 0.04 % Corresponding mounting kit: PR 6012

Request for a quote

MINEBEA INTEC GMBH

Germany

Specially designed for tank and hopper weighing, hybrid scales and high-precision dosing systems. For use in EX zones 1, 2, 20, 21, 22 and FM DIV 1. Ultra-high precision load cell for batching applications Load cell capacity range from 100 kg to 3 t Accuracy class: D1 (0.04 %), C3 (0.015 %), C6 (0.008 %) Corresponding mounting kit: PR 6046

Request for a quote

MINEBEA INTEC GMBH

Germany

The PR 6202 is the world's first load cell designed strictly in accordance with the hygienic design principles developed by the European Hygienic Engineering Design Group (EHEDG). Proven rocker-pin principle Easy corner adjustment by matched load cell output Full stainless steel construction Wide temperature range High overload capacity Resistant against vibrations Hermetically sealed, IP68 (depth of 1.5 m for 10,000 hrs.), IP69K Ex-version available (PR 6202/..E) W&M approval (acc. OIML R 60)

Request for a quote

MINEBEA INTEC GMBH

Germany

Compression load cells from 100 kg to 5 t. Specially designed for tank and hopper weighing as well as basic dosing systems. For use in EX zones 1, 2, 20, 21, 22 and FM DIV 1. Ultra-high precision load cell for batching applications Load cell capacity range from 100 kg to 5 t Accuracy class: 0.04 % - 0.008 % Corresponding mounting kits

Request for a quote

MINEBEA INTEC GMBH

Germany

The weighing module Novego® was specifically developed to meet the increasingly stringent requirements of the food industry. This hygienic all-in-one solution boasts a range of innovative properties to ensure simple, error-free installation and maximum resistance to lateral forces. Hygienic weighing module ensures efficient cleaning High degree of process reliability and precision thanks to the innovative side-force-resistant system Quick and easy commissioning due to smart add-on parts Durable, reliable weighing solution with excellent corrosion resistance

Request for a quote

MINEBEA INTEC GMBH

Germany

The MP 79/79T Bending Beam Weigh Cell is made from stainless steel and is available in a load range from 227 kg to 5099 kg. This weigh cell is specially designed for use in weighing platforms and simple hopper weighing applications. Protection class IP68, IP69K For economic vessel weighing solutions Hermetically welded IP68/IP69 Load cell capacity range from 227 kg to 5.099 kg Accuracy class: 0.02 % Corresponding mounting kits

Request for a quote

MINEBEA INTEC GMBH

Germany

Load cell capacity range from 30 kg to 300 kg. Specially designed for tank and hopper weighing as well as basic dosing systems. For use in EX zones 1, 2, 20, 21, 22 and FM DIV 1. Compact design ensuring a low system height Accuracy class: 0.05 % Extreme wide temperature range Corresponding mounting kits

Request for a quote

MINEBEA INTEC GMBH

Germany

The digital load cells in the Pendeo® Process series from Minebea Intec are specially designed for silo and process vessel weighing. They are based on the tried-and-tested pendulum support principle, which in combination with Minebea Intec installation kits allows for the horizontal expansion or contraction of the vessel without damaging the load cells. This minimises the influences on the measurement signal.

Request for a quote

MINEBEA INTEC GMBH

Germany

As digital weighing solution with the converter Connexx®, the load cell Inteco® offers fast signalling times and optimal transparency in dosing and weighing processes. With an output signal of 2 mV/V, load levels of up to 75 t, accuracy classes up to C6 and high-quality stainless steel, it has a wide range of potential applications. The versatile, innovative weighing solution for silo and vessel weighing Further development of the PR 6201 load cell NEW: Output signal of 2 mV/V NEW: additional load levels 60 t and 75 t NEW: Accuracy class (C6) from 3 t NEW: even higher corrosion resistance All accessories and installation kits of the PR 6201 load cell can still be used

Request for a quote

MINEBEA INTEC GMBH

Germany

The digital Pendeo® Truck load cell is the optimal solution for weighbridges. Its takes the performance of our products to the next level and makes the setup, calibration and operation of weighing systems now even easier and more reliable. Ideally suited to use in weighbridges Standardized, maintenance-free, extremely compact design Extremely robust design in hermetically sealed stainless steel housing Special strain-gauge technology for significantly improved lightning protection High overload range (up to 150 %) 100 % compatible with PR 6221 Reaches stability quickly which ensures short weighing times High EMC compatibility (10 V/m) Suitable for use in ATEX zone 2/22 Additional reliability thanks to diagnostic function

Request for a quote

MINEBEA INTEC GMBH

Germany

The load cell PR 6221 was designed specifically for use in truck scales. Its outstanding precision and long product lifetime cut service and calibration costs, and help to reduce downtimes to a minimum. In combination with the converter Connexx®, the PR 6221 becomes a digital solution.* - Optimum reliability thanks to German Quality * - Precise measurement results for exact load billing * - Top fail-safe performance thanks to high lightning protection * - Optimum protection against waterlogging, frost and de-icing salt * - Also available as a digital solution with converter Connexx®

Request for a quote

MINEBEA INTEC GMBH

Germany

More hygiene for your process vessel weighing. The innovative weighing module is the solution for hygienic applications - designed by EHEDG guidelines. Preassembled weighing module, including load cell, integrated constrainer and lift-off protection, saving installation time Integrated jack-up function to quickly lift the vessel without hydraulic lifters Sophisticated sealing technology ensures an optimum hygienic design EHEDG-certified product

Request for a quote

MINEBEA INTEC GMBH

Germany

Cast stainless steel load cell for use in platform scales and for basic weighing of small to medium-sized containers. The load cell is available in threaded and T-end versions. IP67 protected.Available for use in EX-zones 1, 20, 21. For economic vessel weighing solutions Load cell capacity range from 91 kg to 2.268 t Accuracy class: 0.02 % Corresponding mounting kits

Request for a quote

IFA TECHNOLOGY GMBH

Germany

Gravimetric dosing or weight-controlled dosing is based on the principle of weighing technology. The weight of the weighed material is measured via load cells or weighing cells either directly or by loss-in-weight. IFA Technology offers you specific solutions tailored to your individual needs for weighing, mixing and dosing solids or liquids. We consider your individual requirements and build customised dosing systems for you. The system "IFA-Gravimet" is our standard system in the field of gravimetric dosing. We supply a complete, ready-to-operate pre-assembled weighing, mixing and dosing system. As a complete system for weighing, mixing and dosing liquids, the system can be individually customised to suit your requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Small-size twin screw feeder for powders or rotary tube feeder for pellets and fine-grained media — Feed rates as low as a few grams per hour — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy Power range 1-5 dm³/h

Request for a quote

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Details depend on the characteristics of the medium to be fed (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.) —Applicable feed pumps: piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc. — High-tech weighing system with digital load cell DigiMASS-2 for high weighing accuracy — Heated versions available (electrical, hot water, thermal oil, etc.) Power range - Different Versions 1 - 1000 dm³/h 50 - 5000 dm³/h 100-10000 dm³/h

Request for a quote

FILLTECH GMBH

Germany

Avery compact and flexible filling system for CO 2/N 2O in combination with other Filltech systems like profiFill or uniFill. Highlights Easy, precise and safe to operate For operation in combination with other Filltech systems Individual solutions on demand Optionally available with integrated pump or for central pumping supply Different attachment parts and filling adapters for the filling of several cylinders in the indicated weight range Additional case for accessories and tools Short set-up time for changing parts Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35 lbs. Scale division: 0-7 kg -2 g, 7-15 kg - 5 g Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 24 x 47.5 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells Automatic tare setting Automatic shut-off at target weight Legal for trade Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35 lbs. Sca

Request for a quote

FILLTECH GMBH

Germany

PicoFill Add-on is a very compact and flexible filling system for CO 2 / N 2O in combination with other Filltech systems like uniFill. Highlights Easy, precise and safe to operate For operation in combination with other Filltech systems Individual solutions on demand Optionally available with integrated pump or for central pumping supply Different attachment parts and filling adapters for the filling of several cylinders in the indicated weight range Additional case for accessories and tools Short set-up time for changing parts Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35 lbs. Scale division: 0-7 kg -2 g, 7-15 kg - 5 g Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 24 x 47.5 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells Automatic tare setting Automatic shut-off at target weight Legal for trade Technical Data Filling-range: approx. 50 g - 6 kg/ up to 13 lbs. fill weight Weighing-range: up to 15kg / 35

Request for a quote

FILLTECH GMBH

Germany

A very compact, mobile and user-friendly filling system for a wide range of cylinders with weights up to 6 kilograms. Highlights Variable filling connections Easy, precise and safe to operate Automatic filling process Anodized aluminum frame; stainless steel cover plate Optimal cost/performance ratio Build in pump Legal for trade Technical Data Filling-range: approx. 50g - 6kg/ up to 13 lbs. fill weight Weighing- range: up to 15 kg/ 35 lbs. Dimensions: approx. 600 x 400 x 1200 mm/ 24 x 16 x 47 in. Weight: approx. 50 kg/ 110 lbs. Weighing System Two load cells SysTec IT 1000 industrial weighing terminal Automatic tare setting Automatic shut-off at target weight Manually operated relief with ball valve Optional Filling Connections for Pico-Fill Filling unit for 1/2 in. trapezoid- and side-outlet valves Pneumatic press-on, cartridge filler and other connections on demand

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Mixing Bulk material processing with convincing results With our mixing systems homogeneous mixtures and coatings are produced from various bulk material. This is enabled by our cutting-edge mixing machinery which includes drum mixers, container mixers, Nauta Mixers, high-speed mixers, Rhönrad mixers, swivel screw mixers and other special mixing systems. Modern machinery guarantees quality The mixing machinery at Ebbecke is supplemented by a fully automatic gravimetric load cell weighing plant, as well as by a chopper, nozzle fittings and equipping possibilities for various containers. Technically, Ebbecke Verfahrenstechnik AG is thus equipped for every task imaginable in the area of contract mixing, even for contract mixing of particularly shear-sensitive bulk material. The quality of our mixing machinery proves itself in the technical details: Product-contacting parts consistently made of stainless steel in accordance with the current hygiene standards. Furthermore, all mixing sys

Request for a quote

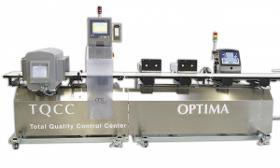

OPTIMA NONWOVENS GMBH

Germany

Metal detection based on measurement of magnetic permeability Check-weighing process with industrial load cells Rejection pushers mounted on a separated frame to avoid any vibrations 5 separate servo driven belts Interface between TQCC and bagger included One HMI for metal detector, check-weigher and rejection Modular design for easy service

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The load cell measures the compression forces between the circular contact surfaces of plunger and tool. The pin on its top side and hole on its lower face are simply provided for mechanical fixing and centering the components correctly. To provide as large a range of mechanical compatibility as possible, the pins/holes are available in different diameters. Attachments are available which clamp onto the press sensors to enable easy mounting of displacement sensors according to the circumstances of use. FEATURES: — Measuring ranges from 0 … 100 N up to 0 … 25 kN — Small, compact design — Pin/hole diameter from 8 mm to 16 mm — Different diameter for pin and hole can be combined — Mechanical overload protection for all measurement ranges

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

With its flat construction this force sensor is specially designed to be fitted to a pedal. By this, the operator's forces for each respective action, for example brake tests, can be measured directly and the reaction of the vehicle or machine can be designated. This applies to real test drives, as well as in driving simulators. Due to the special construction of the membrane, it is irrelevant whether an upright or hanging pedal is concerned. The sensor is designed in a way that unavoidable lateral forces have as little impact on the measurement result as possible. Using a central internal thread on the control surface, various machine-related adaptor parts can be easily mounted. Because the pedal is convex-shaped on its surface, the pedal force sensor has a very rigid base plate and therefore can easily be applied to various geometrics. The mounting can even take place on a pedal with an elastomer covering.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to their small dimensions and sturdy construction, these miniature compression load cells made of stainless steel can be used in a wide range of industrial applications and in laboratories. This compression load cell is easy to handle and its installation is uncomplicated. Its small size makes it perfect for use in very restricted structures for both static and dynamic compression force measurements. The miniature compression load cell model 8415 is a flat cylindrical disc, the bottom of which is closed with a cover. The load application button for receiving the compression forces is an integrated part of the sensor. A strain gage full bridge is applied in the gauging member of the measuring element. This produces bridge output voltage directly proportional to the measured force. The small diameter of the sensors results in high rigidity and a short measurement range. The measuring force has to be applied centrically and free from lateral forces.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to their extremely compact design, these load cells can be used wherever static or dynamic load forces have to be measured in very tight spaces. Model 8416 is perfect for use in micro-technology and just as suitable for measuring tasks in the research and development sector. The ultra-miniature compression load cell model 8416 is a flat, circular disc, the bottom of which is sealed with a cover. The load application button for receiving the compression forces is an integrated part of the sensor. The sensor element inside the body carries a strain gage full bridge which outputs voltage directly proportional to the measurement variable upon application of force. The short nominal measurement distance of the ultra-miniature compression load cells due to their design provides a high degree of rigidity. If needed, the nominal characteristic value can be standardized in the sensor connection cable.

Request for a quoteResults for

Weighing load cells - Import exportNumber of results

35 ProductsCountries

Company type