- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- waste processing

Results for

Waste processing - Import export

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our machinery enables great flexibility at constantly high throughput to recycle your plastic waste efficiently and recourse-saving with help of different recycling processes Currently we run two modular recycling lines for clean, single-polymer and thermoplastic waste. One shredding-grinding line for up to 6.000 tons yearly and one modular shredding-grinding-agglomeration line for up to 9.000 tons which enables parallel or in-line grinding and agglomeration. With those two lines we can process any plastic waste the optimal, resource-efficient way. Since the foundation in 1997 we have developed a deep process knowledge for many types of plastic waste, to produce non-cloggy, free-flowing and dry regrind and agglomerate. After every polymer change our recycling lines are cleaned meticulously to avoid contamination from a polymer-mix. All metal parts are detected by metal detection and the recyclate runs through a dedusting machine before being filled into big bags.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Reducing transportation costs, compressing material for feeding to existing pressed-waste containers or baling presses, or shredding of material for conveyor belt feeding are good reasons for deploying a cardboard shredder. With the EKZ cardboard shredder and FKZ paperboard shredder, ERDWICH’s two rugged machines offer 100% process reliability in a range of form factors. Whether you need to shred packaging or process cardboard waste for feeding into existing conveyor systems, ERDWICH can always offer you a perfect solution tailored to your requirements.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

One of the greatest challenges facing our society is the reclamation of valuable raw materials from electrical and electronic scrap. A global scrap volume exceeding 40 million tonnes a year – a figure forecast to double by 2025 – presents both a challenge and an opportunity. Since even in Germany only some 40% of scrap is currently fed into a waste management process, we may assume that the global rate of waste management is still substantially lower. With additional support from WEEE Directive legislation, this represents enormous growth potential for recycling companies in all consumer-oriented markets. For many years now, ERDWICH has specialised in the reclamation of valuable primary materials from electronic waste with its shredding machinery and turnkey plant solutions. As a result, economical and mature solutions are available for meeting any of these challenges. ERDWICH pre-processing: Whether you’re handling electrical/electronic waste, small/large household appliances,...

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you customised solutions for water treatment using mineral wool wash water plants. Benefit from our extensive experience in the field of insulating materials. Functions of mineral wool wash water plants: Planning, design, construction, assembly and commissioning of systems for the collection and treatment of waste water from the production process Multi-stage filtration and purification of the water using settling tanks with agitators, screening machines, drum filters and hydrocyclones

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANK AND SYSTEM SOLUTIONS FOR WASTE WATER TREATMENT PLANTS Individual, customised container and system solutions have been one of the core business areas of Lipp GmbH for decades. This is demonstrated by the long list of references for completed tanks and equipment that have been implemented in close cooperation with well known engineering firms and companies for industrial waste water treatment plants at home and abroad. From simple, open topped waste water tanks through process vessels with special requirements for stainless steel and sealing materials to fully equipped fermenter types, (SBR, CSTR etc.) for different applications, Lipp offers a wide range of system solutions. Each project is planned and manufactured individually according to specific customer requirements for material, diameter, process instructions etc., and installed and tested if necessary in close cooperation with the partners. The versatility of the Lipp system in combination with process

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR MUNICIPAL WASTE WATER TREATMENT Lipp has for many decades been an established partner of municipal waste water treatment plants, engineers and general contractors in the field of tank and system solutions for municipal waste water treatment. Due to their method of construction as well as flexibility in the choice of materials and ideal diameter – height ratios, Lipp tank and system solutions are especially suitable for the needs of small to large sewage treatment plants. They are ideally tailored to one another, but may also be embedded as individual island solutions into existing systems and are therefore equally popular with planners and end users alike. The stainless steels used and the double seaming guarantee maximum water tightness and durability with low maintenance for a wide variety of waste waters, slurries, process liquids and gases. The versatility in terms of the system solutions offered for municipal waste water treatment plants

Request for a quote

FLOTTWEG SE

Germany

In the process of treating waste water, fine biological sludge is constantly produced during the decomposition process at a sewage treatment plant. For a stable decomposition process in the biological treatment phase, the sludge produced in the secondary sedimentation pond, also known as excess sludge, is removed and fed into the digestion tower. Flottweg's OSE decanters thicken the sludge before it enters the digestion tower. Sewage treatment plants benefit from an even feeding of the digestion tower and can thus optimally use the volume of the digestion tower. The Flottweg OSE decanter is specially designed for sludge thickening. ► Highest gas yield through constant feeding of the digestion tower ► Best possible thickening even with changing feed conditions ► Larger sedimentation volume (due to deep pond and steep cone) enables highest power density (10 - 20 percent) with minimum space requirement

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

There are two different construction types. It's possible to create a design using a little construction space using the customer's data. The Thermo-Fluid S is connected directly between the oven pipe (or the heating system) and the chimney. The operating temperatures are up to 300°C (standard). The Thermo-Fluid S is low maintance with low pressure drop in the flue gas. Depending on the application you can have energy savings up to 15 %. A bigger construction is the Thermo-Fluid M, which is optimised for utilisation of waste heat from process air, flue gas or exhaust air. An energy yield of up to 1600 kW is possible, whereupon the pressure drop in the process air is less than 1.5 mbar. The pressure drop in water circuit is less than 200 mbar. This Shell and Tube heat exchanger is low maintance using the small type of construction. The Thermo-Fluid M modular and the standard temperatures are up to 300°C too. Both Shell and Tube Heat Exchangers are low maintance. One-off or

Request for a quotePWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application The internal transport of residuals and recyclable fractions, e.g. sievings, screenings and material from grit chambers in waste water treatment plants, as well as various media within production processes, is effected for many years now by belt, spiral and screw conveyors. These systems have proven as very reliable and versatile. As a “connecting element” the PWL GmbH & Co. Anlagentechnik KG supplies the optimal suitable conveyor technology for your specific application. We recommend the encapsulated design of spiral conveyors for process and waste water technology. The spiral conveyors impress with their compact design, the robustness towards clogging and the option to be equipped as a spiral press for simultaneaous dewatering of the conveyed material.

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application The PWL Spiral Sieve HXS presents among the fine screens one of the most efficient solutions for small and medium waste water treatment plants and for some industrial branches. Functional Description In one screening system with one drive only the PWL Spiral Sieve HXS offers three functions. Besides sieving and separation of solids from waste and process water the screenings are conveyed and dewatered at the same time from the screening area for further direct discharge into a container or into a downstream conveyor unit, for example into a PWL Spiral Conveyor. Equipped with either a perforated screening surfaces or wedge wire sieve baskets and installed into tank or channel this Spiral Sieve offers a broad field of applications. The swivelling out mechanism and the transport area which is designed as a conveyor trough with removable covers of the PWL Spiral Sieve provide for easiest maintenance. Your Benefit sieving, transportation, dewatering in one system high...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application Standard grit trap contents have an organic proportion of 50 to 80 %. Conventional sand washers are able to dewater the grit trap settlings only partially. But, the high organic content and the lack of dry substance bring on unpleasant odour, high weight and, as a consequence, high costs for disposal. With the PWL Sand Washer the organics in the grit trap can be nearly completely washed out. This results into a reduction of mass of up to 80 % and might cause cost savings of up to 90 % when being disposed on a construction waste landfill. This procedure can be applied in industry, as well, to separate valuable materials from waste. Due to the separate discharge of the various fractions they can be further treated, recycled or disposed. Thus, valuable materials can be returned to the production process and waste material be disposed at low costs and correctly sorted. Function The PWL Sand Washer is fed with a sand-water-mixture. The settled sediment mixture is conveyed...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

The externally fed TanFlow Drum Screen is characterized by its rugged and simple design, as well as by its small footprint allowing for installations with limited space. The TanFlow is employed where it is necessary to separate larger flows of liquid from solids – irrespective of industrial or municipal applications. Even oily and greasy media can be separated. Function The process or waste water reaches the sieve drum surface via the headbox. First, the liquid runs from the outside of the drum into the inside. Thus, the solids which are larger than the chosen wedgewire opening settle on the surface. Due to the continuous drum rotation they are transported to the scraper where a gentle separation of the solids is effected. The cleaned liquid flows after the separation process once again through the drum, this time from the inside to the outside (backwash) where it finally leaves the machine through an outlet pipe. Installation Examples municipal WWTPs wood...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application Increasing fees for sewage water make high demands on in-plant sewage treatment plants. The internally fed sieve drum CenterFlow is a product to face manifold problems, designed for liquid/solid separation in the field of process and waste water of industries or WWTPs. Function The rugged sieve drum is the core of the CenterFlow. Here, the particles are retained and carefully dewatered for further discharge. Within the inlet chamber the flowing-in medium is homogenized and the flow velocity reduced. The tangentially approached sieve surface serves to efficient fine sieving even of high hydraulic loads. Due to the drum configuration the main task can either be a fast solids discharge or a slower passage through the drum if the retained solids are to be, in addition, washed or properly dewatered. With a constant rotational speed and a low drive power this sieve drum machine is a reliable component within the equipment of a plant. The high availability and the large...

PWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application An efficient and reliable fine sieving is essential not only for a comprehensive water recycling but for completely closed water circulations. For these applications, the Drum Filter MDF with mesh sizes between 25 and 2000 µm is the best choice. This filter offers a high capture rate at low operational costs during continuous operation. The choice between different cleaning media is part of the adjustment to the individual site conditions. In addition, different discharge devices and the level controlled drum rotation have to be considered. Function The Drum Filter MDF is a unit made of stainless steel, designed for liquid/solid separation within the field of process and waste water of various industries. From the Drum Filter’s inlet connection the waste water runs off into the filter drum consisting of a steel construction which is covered with a stainless steel wire gauze. The solids settle at the gauze and are transported upwards by the rotating filter drum. The...

ANTHERMO GMBH

Germany

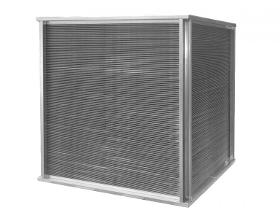

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

BORSIG GMBH

Germany

BORSIG has developed its own boiler design. This boiler design is suitable for all gasification processes. The waste heat boiler is designed as a fire-tube boiler. The hot synthesis gas enters the heating surfaces with a temperature of about 1,400 °C and is cooled down in these tubes to approximately 300 °C. The heat from the synthesis gas is used for generating saturated steam.

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Processing of plastic waste in our recycling lines (shredder, grinder and agglomerator) Contamination separation and dedusting Eventually contract processing of plastic waste.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REILING GMBH & CO. KG

Germany

“We all need to use the natural resource wood responsibly, to protect our forests and the climate by extension!” INDIVIDUAL AND CUSTOMIZED: OLD WOOD COLLECTION AND RECYCLING We assist in disposing of your old wood waste (Categories I – IV) – from single-use pallets to fencing. We offer tailored services: collection/disposal through the Reiling fleet or provision of collection containers; pickup can be flexible or on-demand. For commercial quantities, our 24-hour acceptance is open daily. Using innovative techniques and rigorous controls, we process old wood for various purposes. Our end product is wood chips used in the chipboard industry or to generate carbon-neutral energy in power plants. Contact us for more information or quotes! Your contact person: Anna-Katharina Hinz | Sales Manager Wood Tel.: +49 2383 936031 E-Mail: a.hinz@reiling.de

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our recylcing machinery can process multiple types of thermoplastic polymers in diverse forms. Important is that the waste is clean, contains one polymer only and is thermoplastic. Our largest polymer is PVC. About 60% of the processed plastic waste is rigid or soft PVC. The reaming 30% are mainly PP and HDPE but also LDPE and multiple engineering grade polymers. The plastic waste can be mixed or single-colour (black, white, grey etc.). We buy plastic scrap of the following polymers: We can process many different types of plastic waste independent of form or size. Our recycling machinery enables a flexible recycling of solid, thin-walled and powdery plastic waste.

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

By processing the waste to recyclate the waste is not treated as waste anymore but as a product (secondary raw material). This process excludes the waste originator from any liability risks associated with the plastic waste.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE metal detector system 3000 reliably detects metal parts in conveyed materials on conveyor belts. System 3000 consists of an analysis device and one or several compact detector coils. The MDS coils are mechanically extremely robust, resistant to climate change, water-tight and designed for outdoor use - for example on mobile equipment. EGE metal detectors reliably protect stone crushers, waste compactors, mills and other processing plant which could be damaged by larger metal parts.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

System 3000 reliably protects stone crushers, waste compactors, mills and other processing plant which could be damaged by larger metal parts. The MDV/MU analysis devices of system 3000 feature, dependent on the variant,m a comfortable installation and set-up using automatic calibration, self-monitoring, reset function, pre-attenuation indication, sensitivity potentiometer and test function. Optionally, devices with multiple functions are available in the miniature control cabinet as well as robust water-tight variants for outdoor use. To increase sensitivity or range, it is also possible to connect several coils to an analysis device.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Waste incineration plants, refuse-derived fuel (RDF) incineration plants or incineration plants of any kind. For various types of cranes with internal or external holding ropes. Technical design Low-maintenance or maintenance-free for increased profitability 4-rope grab with half-closed grip Suitable for handling waste of any kind Closing rope devices: Rope nozzles KROGER MAINTENANCE-FREE, rope-protecting, roller-bearing pulley system Rigidly mounted main casing to accommodate the lower rope pulleys, easily move the ropes and reduce wear on them even when the crosshead is at an angle whilst the grab is being operated Solid, removable rope guards Rope pulley bearing: Re-greaseable plain bearing KROGER MAINTENANCE-FREE pulley block system Grab connection bearing: Re-greaseable steel bushing bearing KROGER MAINTENANCE-FREE bearing system Stable shell structure with shells made out of S355J2+N with a wear-resistant edge recessing made of Pantanax steel

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Motor grab systems. A wide range of maintenance-free products Manufactured for tough yet smooth bulk load handling – in sea and inland ports, gravel and sand extraction, and waste processing – our KRÖGER motor grab systems are available in a variety of designs and all come with the KRÖGER “maintenance-free” advantage. To protect the environment and maximise your efficiency.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Our KROGER rope grabs are used on cranes for gravel extraction, port handling and waste processing to lift high and even maximum loads. They are individually designed for 2-point or 4-point suspensions. Their clamping force equally varies, with 3 to 7-fold reeving. All KROGER grabshave low-maintenance or maintenance-free design, which benefits both the environment and your profitability.

Request for a quote

HEXPOL TPE GMBH

Germany

We have engineered a range of TPE compounds specifically designed to address the requirements for automotive mats - the Dryflex AM range. These materials combine the performance of thermoset rubbers with the processability of plastics. Applications for Dryflex AM materials include floor mats, trunk liners, coin mats, fascia mats and trim. For automotive floor mats the materials needs to have high scratch and abrasion resistance. It is also critical that the material is non-slip, even when wet. The material structure of Dryflex AM compounds produces the surface finish and high friction required. Dryflex AM materials are low odour and fogging. They require no vulcanisation and are 100% recyclable during production, making them easier to process than vulcanised EPDM with fewer steps. This means less energy is used and production is faster and more cost-efficient. Benefits of Dryflex AM TPEs Low odour Low fogging Lightweight 100% recyclable - 0% waste Easy to process with short cycle tim

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"The rEvap technology is the perfect solution for small and medium-sized companies that want to close material cycles and minimize disposal costs. The plants are equipped with a plate module. We would be pleased to carry out appropriate preliminary tests for you. Technical details: For process water / waste water up to 1 m³/h Fully automatic Controlled via Siemens SPS Adaptable according to customer requirements All channel geometries possible Suitable for endurance run"

Request for a quoteResults for

Waste processing - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Plastics - industrial raw materials (4)

- Processing and recycling of waste (3)

- Hydraulic equipment (3)

- Heat exchangers (2)

- Metal detectors (2)

- Tanks, metal (2)

- Goods handling systems, continuous (1)

- Treatment of industrial waste water (1)

- Water purification - systems and equipment (1)

- Water treatment products (1)

- Wood chips and sawdust (1)