- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vision systems

Results for

Vision systems - Import export

PAUL LEIBINGER GMBH & CO. KG

Germany

LEIBINGER is offering its customers a straightforward and cost-effective option for quickly and reliably checking the product marking applied by a LEIBINGER inkjet printer in the form of its V-check vision system. V-check does this by automatically comparing printed data such as letters, digits, logos or images against a reference sample, guaranteeing high production reliability.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 5705 series offers high performance with high resolution making it the fastest 5MP self contained vision system in the world, supporting Gigabit Ethernet and the new blazing fast PatMax® Redline™ tool. The In-Sight 5705C offers color image filtering in addition to grayscale filtering and allows you to train multiple color models using the color library to identify which color the target part is. All models are equipped with a full library of proven Cognex vision tools. With the In-Sight EasyBuilder® configuration software, even the most powerful vision tools are accessible to users with little vision experience. For experienced users and complex applications, In-Sight 5705 includes scripting functionality as well as TestRun system validation and Cognex Connect suite of communications protocols.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 5705 series offers high performance with high resolution making it the fastest 5MP self contained vision system in the world, supporting Gigabit Ethernet and the new blazing fast PatMax® Redline™ tool. All models are equipped with a full library of proven Cognex vision tools. With the In-Sight EasyBuilder® configuration software, even the most powerful vision tools are accessible to users with little vision experience. For experienced users and complex applications, In-Sight 5705 includes scripting functionality as well as TestRun system validation and Cognex Connect suite of communications protocols.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 8000 compresses an entire self-contained vision system in an amazingly small form factor. These vision systems are ideal for integrating into tight spaces on robots and hard-to-reach machinery anywhere on the production line. Every In-Sight 8000 vision system model delivers best-in-class performance. Most models are equipped with a full library of proven Cognex vision tools, including Pattern Matching, Filtering, Color tools, Inspect Defects and ID (1D/2D, OCR). In-Sight Explorer combines the guided step by step setup of EasyBuilder with the additional power and flexibility of the spreadsheet for greater control and customizing of application data. Also included is the new scripting function to simplify data-intensive tasks or complex final result logic. TestRun system validation, Cognex Connect suite of communications protocols and the Cognex Explorer control center gives you the tools you need to keep your line operating on schedule and at full throughput.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 7900 series is a full-featured, high-resolution and flexible vision system that performs fast, accurate inspections of a wide range of parts across all industries. With a wide selection of field-changeable and user-configurable lighting and optics (Flexible Image Technology™ FIT™) the modular design is highly field-customizable to your application requirements. The In-Sight 7000 vision system is thoughtfully engineered with the full suite of powerful Cognex vision algorithms and convenient features to help you solve your applications easily and reliably, including a highly visible pass/fail LED indicator light ring around the camera body, an SD-card slot and an IP67-rated housing.

Request for a quote

COGNEX CORPORATION

Germany

In-Sight 8000 compresses an entire self-contained vision system in an amazingly small form factor. These vision systems are ideal for integrating into tight spaces on robots and hard-to-reach machinery anywhere on the production line. Every In-Sight 8000 vision system model delivers best-in-class performance. Most models are equipped with a full library of proven Cognex vision tools, including Pattern Matching, Filtering, Color tools, Inspect Defects and ID (1D/2D, OCR). In-Sight Explorer combines the guided step by step setup of EasyBuilder with the additional power and flexibility of the spreadsheet for greater control and customizing of application data. Also included is the new scripting function to simplify data-intensive tasks or complex final result logic. TestRun system validation, Cognex Connect suite of communications protocols and the Cognex Explorer control center gives you the tools you need to keep your line operating on schedule and at full throughput.

Request for a quote

COGNEX CORPORATION

Germany

The In-Sight 7800 series is a full-featured, powerful vision system that performs fast, accurate inspections of a wide range of parts across all industries. With a wide selection of field-changeable and user-configurable lighting and optics (Flexible Image Technology™ FIT™) the modular design is highly field-customizable to your application requirements. The In-Sight 7000 vision system is thoughtfully engineered with the full suite of powerful Cognex vision algorithms and convenient features to help you solve your applications easily and reliably, including a highly visible pass/fail LED indicator light ring around the camera body, an SD-card slot and an IP67-rated housing.

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

BIZERBA SE & CO. KG

Germany

Complete optical packaging inspection Vision inspection system SealSecure checks the seal and seams on the package, labels and information on the top and bottom or the sides of the products. The stand-alone vision inspection device detects non-conforming packages prior to packaging and rejects them, if there are product, package discrepancies or deviations. The staff are then immediately warned visually and audibly in order to be able to intervene and rectify the problem. Vision inspection system SealSecure prevents extensive and costly rework, eliminating claims and product recalls due to non-conforming packages. In addition, the Vision inspection system SealSecure ensures that only flawless products reach the market or end user. In addition, all the product images are saved in the production system and the relevant production reports are generated, the vision inspection system contributes to complete traceability of the production line. The Vision inspection system SealSecure...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The accessories use for mechanical housing.

Request for a quote

QUELLTECH GMBH

Germany

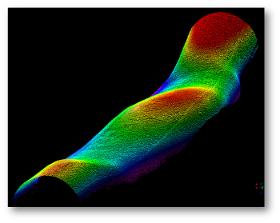

The QS View software package is intended for dimensional control in 2D or 3D QS-View 2D / 3D software for all measuring tasks 3D representation of an irregular body for determination of volume and weight. With the 2D / 3D software a wide variety of parameters can be processed and displayed, e.g. length, width, angle height, gap, presence, volume (resp. weight), seam geometry (height, width), gap dimensions. Due to the modular structure of the software, customized specialties can be added any time. Each module delivers the results to an individual output module. The universal SPC interface allows simple connection to S7 controllers via Ethernet. 2D / 3D software developer kits are available for integrators with corresponding knowhow.

Request for a quote

QUELLTECH GMBH

Germany

Laser sensor Q4 – with a small form factor – Q4 for standard 2D / 3D measuring applications: Low sensitivity against influences of secondary light Measuring ranges from 5 mm to 1000 mm Laser wave lengths starting from UV via blue, red and green through to IR Average measuring speed up to 350 Hz frame The Q4 laser sensor has been designed to meet the requirements of standard measuring applications. Thanks to its increased flexibility, it can be used for several tasks also in complex projects. The dimensions of the ultra-compact version amount to only 86x40x25, at a weight of 140 g. Protective panes and cooling modules are available as an option. The Q4 laser sensor model enables users to obtain stable measuring results also on difficult surfaces, whether mirroring or transparent. The QS-View Standard Software comprises a comprehensive selection of application modules, to be invoked at once without previous programming steps. Customized adaptations are possible any time.

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

QUELLTECH GMBH

Germany

The new QuellTech Q5 Laser Scanner Series combines the advantages of small form factors with both high resolution and scan rate. The sensor disposes of different set-up possibilities with respect to the analysis algorithm. Measurement results are delivered via Ethernet, calibrated in the X / Z plane. Special adjustable algorithms can be selected, extremely useful particularly also for optically most demanding surfaces. Time-consuming calibration tasks for the user are no more required, as the calibration routine runs on board. High Scan Rate with up to 14,000 Profiles per Second Due to an appropriate limitation of the image range (AOI) in X and Z direction, the scan rate could considerably be increased. High resolution and detection frequency with up to 14.000 profiles and 28 Mio. points per second •X measuring range from 10 to 1022 mm •Z measuring range (height) from 5 to 878 mm •Laser wave length blue 405/450nm, red 650nm

Request for a quote

QUELLTECH GMBH

Germany

Defects to be examined in this application are very small, their size is often lower than 0.5 mm – hard to discover by human eye. Rework in the course of the production of the final product however, proves to be complicated and expensive. Large rolls with a diameter of 2 m and a length of 10 m are very difficult to remove and to reinstall. In order to avoid corresponding inconveniencies, it is essential to support the manufacturing process of the rolls themselves by a reliable quality control in the form of an automated final inspection.As the Quelltech Q6 laser scanner features an extremely precise resolution of 4096 Pixels/Profile at a high scan rate, this model proved to be able to meet the requirements and was mounted onto the positioning stage of the grinding machine. Furthermore, an industrial measurement computer was added, used for the analysis software of the point cloud. On the basis of this configuration, the entire roll surface could be recorded on a helical path.

Request for a quote

QUELLTECH GMBH

Germany

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

- Requirements: For extremely heavy duty applications - Outer jacket: TPE - Hydrolysis and microbe-resistant - Silicone-free - UV-resistant - Oil resistance: Oil-resistant according to DIN EN 60811-404, resistant to organic oils according to VDMA 24568 with Plantocut 8 S-MB by DEA

Request for a quote

SAMSYS GMBH

Germany

With the robot camera Eyes from OnRobot, the provision of image processing for almost all collaborative applications becomes easy and cost-effective. Eyes is suitable for the sorting of a large number of objects. For example for CNC machines with metal parts defined by their outer shape and many other pick-and-place applications where alignment is important. Calibration and part recognition with only one single shot takes only a few minutes. Programming is intuitive and fast. And with Eyes’ advanced, affordable 2.5D vision, you benefit from depth perception and the ability to stack parts without adding complexity. The simple one-system setup for all leading robot manufacturers comes with software that is easy to install and program. Even employees without a technical background can perform the setup. Calibration and part recognition with a single shot. Simply take an image of the work surface to calibrate the camera view. One image for each part you want the system to detect.

Request for a quote

XIMEA GMBH

Germany

The xiC camera line is highly versatile with a wide range of the most modern global shutter CMOS sensors up to 24.5 Mpix in resolution. The ultra-compact form factor, barely larger than the C-mount, combined with micro-B, type-C, and flex ribbon connectors make these cameras the perfect fit for various applications, especially for automation and embedded vision systems. For the same form-factor and sensor options, but increased bandwidth of 10 Gbit/s resulting in doubled frame rates, there is the xiX family. - Compact cameras with Sony Pregius™ sensors - 26 x 26 x 33 mm - Fast speed from 2.3 Mpix at 165 FPS to 12 Mpix at 31 FPS - Cool economy - Low power consumption with under 3 watts

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Improve lighting performance with reflective media For instrumentation and testing systems, our POREX Virtek™ sintered PTFE sheets and molded 3-D parts offer multi-directional light, ideal for machine vision systems and integrating spheres where uniformly lighting surfaces of different geometries is a must. Constructed with outstanding reflectance, POREX Virtek™ PTFE: Minimizes glare, with its 100% Lambertian reflection of light. Supports itself when handled - Does not require a backing or support scrim for handling. Supports versatile assembly options – Heat staking or vibrational welding can be used to secure the POREX Virtek™ PTFE to the lighting or housing structure.

Request for a quote

XIMEA GMBH

Germany

The xiQ camera series is highly versatile with a selection of popular and established CMOS sensors. The ultra-compact form factor, barely larger than the C-mount, combined with micro-B, and flex ribbon connectors make these cameras the perfect fit for various applications, especially for automation and embedded vision systems. Board-level variants enable custom intgerations into devices and systems, while taped-glass sensor options minimize interference effects in photonics applications. - Most compact cameras - 26.4 x 26.4 x 26 mm small and 27 grams - High frame rate: 500 FPS at VGA and 1000 FPS at 640 x 400 - Low power consumption down to 1 W and minimal heat dissipation - 5 Gbit/s interface 400 MB/s data throughput

Request for a quote

BIZERBA SE & CO. KG

Germany

Checkweighing for dry areas and non-food applications Bizerba CWDmaxx series checkweighers are designed as entry-level checkweighing models for up to 250 weighings per minute. With an IP54 protection level the CWDmaxx is the first choice for all applications not requiring wet cleaning. It is built with a modular construction allowing for configurations of up to 5 belt modules to be made on one checkweigher, tailored to the specific application or areas that it is sited. Additionally the checkweighing systems are extremely flexible. Due to the modular design all the Bizerba checkweighing systems can easily be integrated with existing inspection systems to include x-ray food, food metal detectors and vision inspection systems. You may also be looking for weigh price labelling systems. Our GLM-Ievo range can boast a labelling speed of up to 170 packages per minute. The dynamic checkweighing system CWDmaxx is ideal for non food, we have an entire range of inspection systems for all...

Request for a quote

BIZERBA SE & CO. KG

Germany

Standard Dynamic Checkweigher for quality assurance at the highest level This standard dynamic checkweigher is available in a large number of combinations including combi checkers with a metal detector. Or to be used with an end of line vision inspection system LabelSecure The CWEmaxx series dynamic checkweigher normally used in the food industry mainly in middle and high-performance settings. In the non-food area they are used in lines with high output and for weighing ranges of up to 15 kilograms. Alternatively if you are looking for more hygienic dynamic checkweighers then you may want to consider the CWPmaxx. A checkweigher that is perfectly suited to food processing where cleanliness and hygiene needs to be of the very highest standard. Furthermore if you are looking for a smaller unit, then you may want to look at the new CWD checkweighers. As a result this will weigh and check up to 250 items per minute. Also consider the other model in this range is the CWFMaxx. This...

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Hard film display panel for A4 information sheets. With universal punching and welded tabs. • Display panel made of crystal-clear hard film for A4 format information materials • Ideal for price lists, catalogue pages, illustrations, photos, etc. • Indelible and suitable for scanners • With reinforced 60 mm tab in 5/5 partition for visual distinction and blank insert sheets • For use with base elements equipped with a pivot mechanism • Can be filed thanks to universal punching in profile strip

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The STS-B was developed for the simple aggregation of pharmaceutical packs into a bundle. For this purpose, the barcodes of serialized products are captured from below by the vision system through a scratch-resistant glass plate. The distance between camera and barcode therefore always remains the same. The maximum working surface is 420 mm (W) x 300 mm (D). The detected serial numbers are marked in green so that they are easy for the operators to understand. Depending on the configuration, the system can compare the recorded serial numbers with the default values of the L3 installation. Particular attention was paid to user guidance (workflow) in order to achieve maximum process reliability. In order to completely fill the carton layer(s) or spaces, barcodes that cannot be placed with the barcode facing upwards due to their orientation can be manually added in each layer by the integrated handheld scanner to complete the respective layer or carton.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

To serialize vials and other cylindrical products, we rely on the proven quality and reliability of our labelers. In order to achieve the best possible grading of the serialisation barcodes, we integrate thermal transfer printer or marking laser units directly on the label applicator. The vision system immediately inspects the print data after the printing process. If the inspection shows a negative result, we optionally offer a label reject station which automatically removes the label from the process and therefore does not waste a „good product“. Both the vision system and the print engine are fully integrated in the touch panel HMI. Shift registers in the label applicator as well as in the complete system enable product and label tracking through the complete system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This workstation enables the manual serialisation of drug packages and their aggregation into shipping cases. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system as it passes by and then manually placed in a shipping carton. As soon as it is filled, the downstream thermal transfer label printer creates an individual serialisation label. The correct print data and print quality are permanently monitored by a vision system. The operator places the medicine products to be serialized on a reference edge at the infeed. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product stops at a certain position marked by red LEDs. The removal of the rejected product must be confirmed by pressing a button on the HMI.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The products are manually placed on the conveyor belt, printed from above and collected at the end of the system. The portable system is equipped with a Wolke m610 Touch thermal inkjet system. An upgrade to a manual serialisation system with b+b Linemanager and Full Vision System is optionally available. The conveyor belt is driven by a powerful stepper motor with constant speed. The conveyor belts are provided with crossbars at regular intervals to achieve constant product guidance and thus a consistent print result. The distance between the two toothed belt conveyors can be easily adjusted in order to process different product widths. For processing slightly slanted products, the positions of the crossbars can also be adjusted to each other.

Request for a quoteResults for

Vision systems - Import exportNumber of results

60 ProductsCountries

Company type

Category

- Machine vision system (38)

- Chemicals and pharmaceuticals - packaging machinery (6)

- Lighting, street, industrial and commercial (4)

- Sensors (4)

- Cameras, cinematographic (2)

- Measurement - Equipment & Instruments (2)

- Monitoring and control equipment (2)

- Surface inspection systems (2)

- Food supplements (1)

- Bending machine tools (1)

- Electric cables (1)

- Electronic data processing - software (1)

- Labelling machines (1)

- Marking - diverse products (1)

- Printing (1)

- Robotics (1)

- Tapes, adhesive (1)

- Vitamins and provitamins (1)