- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vertical conveyors

Results for

Vertical conveyors - Import export

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer serpentine conveyor has stood the test of time for transporting general cargo vertically. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. The chain is optionally equipped with rubberised elements so that large gradient angles can be overcome. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. By connecting a serpentine conveyor that conveys upward and one that conveys downward, the machine can be used as a storage system. Technical data —Conveyor body material: stainless steel —Gradient angle: up to 6° —Chain widths: 82.5 mm, 114.3 mm, 190.5 mm —Conveying speed: up to 50 m/min —Product weight: up to 5 kg Optional equipment —Moving deflecting pulleys —Product guides,design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —accessories: sensors, stoppers, etc.

Request for a quote

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

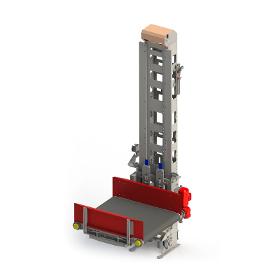

The DAMBACH Vertical Conveyor lifts efficiency to the next level. The free-standing steel construction utilizes warehouse space optimally. The consistent use of poka-yoke techniques and modularcube design allows both fast installation as well as subsequent positioning in confined conditions. Almost any flow of materials can be taken care of with diverse load-handling devices and conveyor elements – two pallets lengthwise or crosswise, a corner transfer module with or without a change of orientation of the conveyed item, and much more. The DAMBACH Vertical Conveyor is one of the highest performing on the market. Each jack can be delivered with preinstallation and decentralized controls. Deepfreeze compatibility up to -28°C comes included at DAMBACH. Compact construction, small lower approach dimensions Inherently stable multiple-column design for heavy loads: up to 3,000 kg Lift speeds up to 240 m/min, lift heights up to 35 m

Request for a quote

BEZNER ANLAGEN- UND MASCHINENBAU GMBH

Germany

When your production or recycling process includes different levels in height or your facility is compact, implementing a state of the art elevator conveyor is an efficient solution.

Request for a quote

HOCHRAINER GMBH

Germany

The availability and output of a production system is only as high as the process reliability of its feeding systems allows. Thanks to more than 35 years of experience as a system supplier for assembly technology and custom machines, we can implement a large variety of applications tailored to customers' requirements;

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. Advantages & benefits energy and space-saving vertical conveying that's gentle on the material low-maintenance continuous operation easy-to-clean, hygienic design natural cooling of the bulk solid during the conveying process thanks to long dwell times bulk solids cooled either directly by air or indirectly by water through the use of double bottom or laser-welded Thermplate® bottoms as the spirals

Request for a quote

HO-MA GMBH

Germany

Our ascending conveyors (dosing elevators) are designed for different volumes. Products are fed as bulk material to downstream machines. Dosing elevator and feeding system for bulk material

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits energ

Request for a quote

WHITE STEEL GMBH

Germany

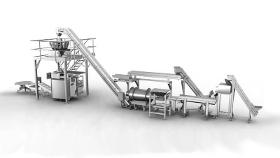

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Cheese chopping machine SCADA and HMI with a touch screen system Hardened stainless steel slicer and 3d chopping system Cups feeder system Antistick powder processing system Vertical conveyor transfer system Automatic suppress distribution system Electro pneumatic weighing cells 3 levels weighing cells Weighing tower Packaging machine Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Bottles and caps sizes, types and shapes Type of metal used S.S 316/304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous cleaning and blowing rotary system Hightech sensors HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Vertical blowing system. Servo conveyor system

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer vertical conveying system is used to overcome differences in height in product lines. The gripper technology permits space-saving vertical transport. Bottles, glasses, tins, cartons, bundles, etc. can be transported using this conveying principles. Technical data: —Chain width: 46 mm/114 mm/254 mm —Conveying performance: up to 60,000 units/h —Difference in height: up to 8m/12m/12m —Product weight: up to 15kg/40kg/40kg —Product width: 15 - 200 mm/20 - 450 mm/20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer spiral conveyor has stood the test of time for transporting differently-sized and -shaped products vertically. The open construction prevents dirt deposits. Common drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears. The mat chain is equipped with rubberised elements so that large gradient angles can be overcome. Technical data: —Conveyor body material: stainless steel —Difference in height when transporting upward: up to 5 m —Difference in height when transporting upward: up to 7 m —Chain widths: 190.5 mm, 304.8 mm, 381.0 mm, 457.2 mm —3 configurations: 0°, 90°, 180° —Conveying speed: up to 50 m/min —Product weight: up to 25 kg —Optionally with lane divider Optional equipment: —Product guides, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —other accessories, such as sensors, stoppers, etc.

Request for a quote

STEINER GMBH & CO. KG

Germany

Transporting recycling materials presents particular challenges for conveyor technology. The spiral conveyors for recycling materials need to be able to withstand materials with very different properties, unlike when transporting raw materials in industrial production processes or homogenous material such as granulates or pellets. In addition, the sturdiness in regards to environmental influences cannot be underestimated as a decisive factor for the longevity of the conveyor system as a whole.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

Overcome heights, safely and precisely. With its precise and efficient lifting unit, the Vertical Transporting Unit performs a real show of strength – with ease! The belt conveyor element incorporated into the baggage lifter is raised and lowered precisely using a lifting unit with two steelreinforced tooth belts. This maintenancefree lifting system has been tried and tested for decades. Between the two upper and lower end positions, any intermediate destinations can be reached. It is also possible to use the Vertical Sorting Unit in flight baggage systems with a container system. An appropriate Motion06 or FMH conveyor can be incorporated to work with the lifter. VTU – 420/660 Low Starting Height Low overall starting height possible. Any Height Requirements Ultrasimple adjustment for the required input and output positions. No Maintenance Maintenancefree lifting system thanks to lifetime lubricated bearings and optional toothbelt drive.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The MULTIFLEX from DAMBACH sets new standards for throughput, flexibility and efficiency. It comprises three perfectly coordinated modules with seamless interfaces: the proven COMPACT SHUTTLE, the high-performance vertical conveyor LIFT and the newly developed CARRIER. In analogy to the small-part-shuttle technology, the MULTIFLEX enables multi-deep storage and highly dynamic commissioning of various types of pallets. In addition, the compact design of the DAMBACH-shuttles and vertical conveyors ensure a very high storage density. With this modular structure, the MULTIFLEX is flexibly adaptable to different challenges. The fields of application for this pallet-shuttle-system are as variable as its three configurations. It is suitable, for instance for cold storage, buffer storage, dispatch warehouses, sequence storage, commissioning warehouses or supply warehouses – But also for compact warehouses with low throughput.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

The new FLEXON SafeTopChain was designed with a completely closed upper surface, minimising the risk of crushing in curves or deflections and offering maximum stability for products and workpiece carrier systems. The special surface also enables even the smallest parts to be transported risk-free. Highlights: • Requires the same guides as the normal plastic multiflex chains from the 1700 Series • By using turning disks with a minimum radius of 123.5mm, dynamic friction is replaced by rolling friction; this allows longer conveyors with more curves, as well as vertical/spiral conveyor systems to overcome gradients and providing buffering. • Improved chain geometry enables the use of wider sprockets, thus reducing wear through lower surface pressure when teeth engage.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Gentle transport of products and high performance due to continuous chain run • Intermediate buffering of several products possible • Up and down movement with same side or opposite side infeed/outfeed Vertical lifts make material flow across several levels possible and are used wherever goods need to be transported vertically - they are ideal for the vertical transport of boxes, trays, plastic containers, bundles, pallets, and bags within automatic conveyor systems. Vertical Lift SPF1S: Transport direction in “S” form. Outfeed side always opposite the infeed side. Vertical Lift SPF1C: Transport direction in “C” form. Outfeed side always on the infeed side.

Results for

Vertical conveyors - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Food industry - machinery and equipment (4)

- Conveyor systems (4)

- Conveyor belts (3)

- Storage equipment and systems (2)

- Bottling and filling - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Mechanical transmission systems and components (1)

- Palletising machinery (1)