- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- valves for gas

Results for

Valves for gas - Import export

STAIGER

Germany

In powered mode, the field strength generated in the solenoid pulls the plunger against the spring tension out of the non-powered position. Solenoids for DC and AC voltage add considerably to the range of technical variants. As the solenoid encompasses the plunger guide tube and the plunger moves in this encapsulated structure, these solenoid valves are called plunger valves.

Request for a quote

CARL FRIEDRICH USBECK KG

Germany

outside thread M10 x 1, CE-0085CQ0255

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• THERMO-AW valves are used for the reliable regulation of air, superheated steam and flue gas flows. The maximum permitted temperature may be, depending on design, up to 600°C. • In order to systematically avoid corrosion problems, we exclusively use stainless steel alloys to make our THERMO-AW valves. Our standard working materials are 1.4301, 1.4541 and 1.4571. • THERMO-AW valves are controlled manually, electrically or pneumatically. All brands can be used for the drive. • THERMO-AW valves are metallically sealed and function without any additional sealing materials. • The leakage rate is less than 0.1 % (based on the cross-section). THERMO-AW valevs are 100 % leak-proof against the surrounding area. • Our construction departement together with our in-house production allows us to deal with virtually any customer requests. • Due to systematic standardisation in detail and our long-term experience, THERMO-AW valves are not prone to malfun

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• THERMO-AW valves are used for the reliable regulation of air, superheated steam and flue gas flows. The maximum permitted temperature may be, depending on design, up to 600°C. • In order to systematically avoid corrosion problems, we exclusively use stainless steel alloys to make our THERMO-AW valves. Our standard working materials are 1.4301, 1.4541 and 1.4571. • THERMO-AW valves are controlled manually, electrically or pneumatically. All brands can be used for the drive. • THERMO-AW valves are metallically sealed and function without any additional sealing materials. • The leakage rate is less than 0.1 % (based on the cross-section). THERMO-AW valevs are 100 % leak-proof against the surrounding area. • Our construction departement together with our in-house production allows us to deal with virtually any customer requests. • Due to systematic standardisation in detail and our long-term experience, THERMO-AW valves are not prone to malfu

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• THERMO-AW valves are used for the reliable regulation of air, superheated steam and flue gas flows. The maximum permitted temperature may be, depending on design, up to 600°C. • In order to systematically avoid corrosion problems, we exclusively use stainless steel alloys to make our THERMO-AW valves. Our standard working materials are 1.4301, 1.4541 and 1.4571. • THERMO-AW valves are controlled manually, electrically or pneumatically. All brands can be used for the drive. • THERMO-AW valves are metallically sealed and function without any additional sealing materials. • The leakage rate is less than 0.1 % (based on the cross-section). THERMO-AW valevs are 100 % leak-proof against the surrounding area. • Our construction departement together with our in-house production allows us to deal with virtually any customer requests. • Due to systematic standardisation in detail and our long-term experience, THERMO-AW valves are not prone to malfun

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

Standard turning valves combined in a T-joint • from Ø 100 mm to Ø 1000 mm • designed and produced according to customer specifications

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

Standard turning valve • from Ø 100 mm to Ø 1200 mm • variable length • designed and produced according to customer specifications, the flanges as well

Request for a quote

THERMOTEC PRODUKTIONSGESELLSCHAFT MBH

Germany

• THERMO-DK are used for the reliable regulation of air, superheated steam and flue gas flows. The maximum permitted temperature may be, depending on design, up to 600°C. • In order to systematically avoid corrosion problems, we exclusively use stainless steal alloys to make our THERMO-DK valves. Our standard working materials are 1.4301, 1.4541 and 1.4571. • THERMO-DK valves are controlled manually, electrically or pneumatically. All brands can be used for the drive. • THERMO-DK valves are metallically sealed and function without any additional sealing materials. • The leakage rate is less than 1 % (based on the cross-section). THERMO-DK valves are 100 % leak-proof against the surrounding area. • Our construction departement together with our in-house production allows us to deal with virtually any customer requests. • Due to systematic standardisation in detail and our long-term experience, THERMO-DK valves are not prone to malfunctions.

Request for a quote

HOPPECKE BATTERIEN GMBH & CO. KG

Germany

The sun | power VR L valve regulated lead acid batteries are specially designed for high energy throughputs and are ideally suited for cyclic applications. They are characterized by excellent cycling properties during operation with partial discharge (Partial State of Charge - PSoC). In conjunction with the extensive capacity range, they are the battery of choice for village power supply. Other typical applications include emergency power supply, security lighting and grid services. The proven format according to DIN 40742 and the possibility of horizontal operation make the sun | power VR L battery versatile and furthermore provide the necessary flexibility for optimal space utilization.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Leak detector high detection sensitivity for pressurised piping and containers, e.g. on compressors, steel bottles, fittings, shut-off valves, breathing devices, oxyacetylene gas and inert-gas arc welding devices, Bunsen burners, valves, screw fittings of compressed-air lines etc. Suitable for compressed air, refrigerant, acetylene, butane, natural gas, carbon dioxide, gaseous oxygen, propane, town gas, nitrogen, hydrogen and, ammonia Suitable for checking the safety of systems with combustible gases and for avoiding financial losses through unrecognized leaks Advantages and benefits Frost-proof to -15°C Saves energy and warns of gas loss Contains corrosion protection inhibitors Tested by the DVGW in accordance with DIN EN 14291 Non-combustible Economical in use

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

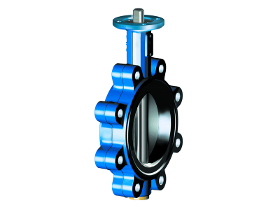

Resilient Seated threaded butterfly valve for gas Verwendung: for Gas

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERC ADDITIV GMBH

Germany

ERC LPG GasLube Premium is designed for the protection of valves and valve seats in LPG-powered vehicles and is suitable for all commercially available additive dosing systems. THE EFFECT As a result of the lubrication qualities lacking in the fuel for LPG operation, special additives must be supplied to the combustion chamber by means of a dosing unit for the optimal lubrication and protection of the valves against severe stress during the combustion process. THE ADVANTAGES AT A GLANCE - Protects valves and valve seats against wear - Cleans the injectors and the fuel system - Reduces harmful emissions - Extends the engine service life - Tested by DEKRA

Request for a quote

ERC ADDITIV GMBH

Germany

ERC LPG GasLube Special with the special formula is designed for the protection of valves and valve seats in LPG-powered vehicles and is suitable for all commercially available additive dosing systems. Especially the heavy stressed inlet valves are protected. THE EFFECT As a result of the lubrication qualities lacking in the fuel for LPG operation, special additives must be supplied to the combustion chamber by means of a dosing unit for the optimal lubrication and protection of the valves against severe stress during the combustion process.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for either gas or liquid flow measurement. These meters can also be fitted with integrated manual flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The RCV Plus™ Gas Mixing System is a combination of flow meters specifically designed to monitor and control the ratio of two gases. It consists of an RCV Plus™ and a FLO-TRONIC Plus™. The RCV Plus™ utilizes a micro-processor that continuously compares a preset ratio to the real-time ratio of the two gas flows, as measured by the FLO-TRONIC Plus™, and the ratio control valve itself. Using a stepper motor, the RCV Plus™ continuously adjusts the flow metering needle-valve to precisely maintain the preset gas ratio. The real-time ratio is continuously displayed on the LCD screen of the RCV Plus™. Included in the RCV Plus™ is an optional input for the addition of a trim gas, which is frequently used for process control. Trim gas addition is additive to the ratio. When trim gas is used, the continuously displayed real-time ratio then includes the trim gas addition.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for gas flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™ meets current NFPA86...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for either gas or liquid flow measurement. These meters can also be fitted with integrated manual flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The FurnaceMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every FurnaceMeter™ comes complete with a 10point...

Request for a quote

EWM AG

Germany

— MIG/MAG pulse welding machine with optimised synergic characteristics for welding steel — Pulsed MIG/MAG welding, MIG/MAG welding, MMA welding and gouging — Significantly less spatter formation and therefore less finishing work thanks to the pulse function — Welding with solid wire and flux cored wire — Drive 4X Steel: Connection socket for electrode holder on the wire feeder as standard — Drive 4X Steel D200: Adjustment of the gas quantity directly on the wire feeder via the gas control valve as standard. — Factory-fit option: Extra gas valve for increased safety — Infinitely adjustable arc dynamics (choke effect) — Adjustable start and end-crater functions — Synergic or manual welding operation

Request for a quote

STAIGER

Germany

• Sizes: Ø 7 mm, Ø 15 mm, Ø 21 mm; • Application: Neutral and mildly aggressive liquids, gases and vapors; • direct actuated; • 2-way valves and 3-way valves, NC; Spider valves are allocated to the micro valve category (outside diameter 7 mm). The anchors installed in the micronized valves have the shape of a disk. In energized status, this so-called flat armature is pulled against the magnetic yoke component group. If the coil is deactivated, the leaf spring joined to the flat armature presses the seal positioned on the spring-armature assembly unit against the valve seat. These quick-acting valves owing to the small mass of the installed armature achieve switching phases in the millisecond range. As these valves predominantly featuring cartridge connections have an almost frictionless armature movement, they have a capacity of up to 4 billion actuations, depending upon operation mode. Spider valves may also be triggered via so-called pulse width modulation.

Request for a quote

OPEN GRID EUROPE GMBH

Germany

Maintenance and repair work on the natural gas network is generally carried out with the pipeline being gas-free, so the relevant pipe sections are isolated by installing valve assemblies and the gas in the isolated section is vented to atmosphere. By using our mobile compressors – individually or in highly efficient parallel operation – the network operator can transfer the gas from the isolated pipe section to another part of the system so it does not have to be vented to atmosphere. Connection points for the mobile compressors are available e.g. in the area of the main line valves or can generally be retrofitted. It makes economic sense to transfer the gas to another as this guarantees responsible handling of this primary energy source and makes a substantial contribution to protecting the environment. Services offered: Pipeline recompression until lowest residual pressure < 3bar Reduction of methane emissions by up to 95% Responsible handling with primary energy

Request for a quote

KTW TECHNOLOGY GMBH

Germany

KTW SmartValve technology: low-wear, easy to maintain, suitable for gases, liquids and food

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

Monitoring of oxygen concentrations in bioprocesses in real time offers the possibility to learn about the actual metabolic state of the culture and use the information for process optimization. Values like OUR, OTR, RQ or even feeding strategies are essential for process control and optmization. BCP-O2 oxygen analyzers in the simple PA housing have a space saving design and are suitable for small scale stuides (e.g experiments in shake flasks) up to industrial scale processes. Due to the integrated automated temperature and pressure compensation gas cooling, specific valves or pipes are unnecessary. Gas concentrations can be measured directly in the process without expentiture.

Request for a quoteResults for

Valves for gas - Import exportNumber of results

31 ProductsCountries

Company type

Category

- LPG (2)

- Valves, hydraulic (1)

- Valves for industrial fittings (1)

- Accumulators and batteries (1)

- Construction - Machines & Equipment (1)

- Dosing - machines and equipment (1)

- Gas - production and distribution (1)

- Pipe and tube fittings - ferrous metal (1)

- Sensors (1)

- Silicones (1)

- Steel (1)

- Valves for sanitary fittings (1)

- Welding, soldering and brazing - equipment and supplies (1)