- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum heat treatment

Results for

Vacuum heat treatment - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

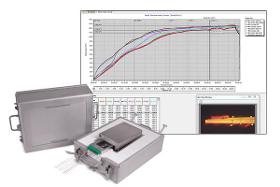

The Datapaq Vacuum Heat Treatment System from Fluke Process Instruments features the Datapaq TP6 data logger, choice of thermal barrier (TB45 or TB46), thermocouples and our intuitive Insight™ software to create a complete solution. The Furnace Tracker Systems that include the Datapaq TB45 series of thermal barriers can operate in temperatures up to 1050°C (1922°F) and the TB46 series can withstand temperatures of up to 1200°C (2192°F). Both are designed for use in vacuum and carburizing applications and can operate in pressures up to 20 Bar (290 PSi). Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ TP3 data logger * 10 or 20 thermocouple channels * Temperature range: -100 °C – 1370 °C/-148 °F – 2498 °F * Sample interval: 0.1 sec – 50 min without telemetry; 1 sec – 50 min with RF radio data transmission * Memory: 3.6 million data points * Robust stainless-steel machined case * High logger accuracy: ±0.3°C (±0.5°F) Comprehensive thermal barrier range for * Heat treatment and TUS * Vacuum carburizing and vacuum heat treatment * Aluminum solution treatment and age hardening * Steel slab and billet reheat * Controlled atmosphere brazing * Aluminium vacuum brazing Specialized software for TUS applications is trusted by hundreds of our customers to meet the stringent requirements of AMS2750E and CQI-9 certifications. Fluke Process Instruments offers a wide variety of PTFE, glass fiber or mineral insulated thermocouples to withstand harsh environments and high temperatures, conforming to the highest standards and providing the most accurate data possible.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Inductively heated vacuum heat treatment furnaces with high operating temperatures specially for the manufacture of hard materials. Standardized components for a broad application spectrum and useful space volumes from 34 to 338 litres. Applications: IOV furnaces are used for all high temperature processes and serve for sintering and heat treatment processes such as degassification, graphitizing, destillation, impregnating, infiltration, reducing and carburization. Benefits for users: An extremely robust type of system, especially appropriate for processes where dust incidence or high temperatures are involved.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

OV heat treatment furnaces are high performance most efficient furnaces with a wide working-temperature and application range. Due to the compatibility with all kind of process gases and the fully automatic process runs they are especially suitable for the economic application in industrial productions for example to produce hard metals or the cleaning and purification of graphite. Applications: • operating temperatures up to 1.100 °C: heat treatment, brazing, reduction, degassing and debinding • operating temperatures up to 1.350 °C: heat treatment, brazing, degassing, debinding and sintering • operating temperatures up to 1.600 °C: debinding and sintering of hard metals • operating temperatures up to 1.800 °C: sintering of non-oxydic ceramics • operating temperatures up to 2.000°C: CVD- and pyrolytic processes, degassing, cleaning, sintering • operating temperatures up to 2.400 °C: CVD-processes, degassing, cleaning • operating temperatures above 2.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

High-vacuum heat-treatment furnaces with integrated pressing unit and power-regulated resistance heater elements (Hot Press). Used for diffusion bonding and forming processes under high vacuum conditions as well universal use for thermal treatments and processes where particularly demanding requirements and sophisticated materials are involved.

Request for a quote

FRIGORTEC GMBH

Germany

Using the DEBUGGER method (heat treatment) from FrigorTec, the DEBUGGER DB18 has proven its effectiveness in killing insects, larva, and eggs, for decades. This method increases the air temperature to a range between 45°C and 60°C, and keeps it there, so that pests die off without using chemical substances, thus preventing damage to buildings and their fittings. A power distributor is required depending on the size of the installation site or the number of devices, and we recommend using one or more SCRAMBLER SC 6000s to save energy. Fields of application > Specially developed for large spaces, e.g., mills, bakeries, the food-processing industry > Often used in spice and coffee processing, as well as in the tobacco industry, muesli manufacture, and small animal feed production > Combine several DEBUGGER DB18s in very large rooms and halls

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Vacuum heat treatment - Import exportNumber of results

6 ProductsCountries

Company type