- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vacuum forming

Results for

Vacuum forming - Import export

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Preparation of the material components under vacuum and injection into an evacuated mold.

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

The vacuum forming process, implemented with simple tools, is ideal for three-dimensional shaping. In modern thermoforming machines with a table size of 1000 x 660 mm up to 2000 x 1200 mm, both negative and positive moulds can be used. Furthermore, we can process the components with our 5-axle-milling-machines afterwards.

Request for a quote

ROSE PLASTIC AG

Germany

High-quality plastic cassettes in modern design. Ideal for all kinds of drill bit sets, precision tools, shank tools, special tool sets and spare parts Modular concept – cassettes can be combined with individual foam inserts or vacuum formed inserts Intergral secure locking mechanism to prevent unintended opening on impact Adjustable and flexible length stop for tools

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA POR is porous and has a smooth surface structure. The product is characterized by a high stability, pressure-resistance and a long-term heat resistance of over 190°C. It is especially suitable for moulds with fine and complex structures. The good air permeability leads to a uniform stretching of the foil in the process of thermoforming. With this innovative product the annoying drilling of vacuum holes becomes obsolete and thus no visible markings are left on the thermoformed foil. Larger dimensions can be achieved by screw connections. Longer and wider dimensions by gluing. ALWA POR is easily machinable: Sawing, drilling, grinding, polishing. It also remains porous after polishing. ALWA POR is especially suitable for vacuum thermoforming and vacuum forming and is additionally suitable for - aeration of aquaria, fishponds and sewage treatment plants, - venting of injection moulds and blow moulds, - any proceedings of hot steam or water steam processing, - vacuum clamping

Request for a quote

FRIMO GROUP GMBH

Germany

One Concept, Many Applications FRIMO EcoForm machines provide state of the art technology that stems from more than 25 years of thermoforming expertise. These machines have the most modern technology in a compact, user-friendly form. They are designed as standardized single-station machines for vacuum forming and vacuum laminating films and sheet materials. They can also be used in the IMG ( In-Mould Graining) process. EcoForm Thermoforming Machines for Plastic Sheets EcoForm thermoforming machines for plastic sheets are the result of continuous product development and improvement and offer a concept superior in many technical details and convincing in terms of economic efficiency, operating convenience, and process reliability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % PTFE Fiber with special PTFE Dispersion Characteristics In applications with high pressure or vacuum, die formed bullrings of S4 (no food approval) are recommended Low coefficient of friction and displays low stem/spindle frictions Long lifetime No ageing Minimized maintenance and readjustments Characteristics In applications with high pressure or vacuum, die formed bullrings of S4 (no food approval) are recommended Low coefficient of friction and displays low stem/spindle frictions Long lifetime No ageing Minimized maintenance and readjustments Operating range Pressure [p max]: 25 bar, Velocity [v max]: 2 m/s Pressure [p max]: 250 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.80 g/cm³ Main application Valves Fittings Gate valves Flaps Plunger Door and lid seals Suitable for Pulp and paper industry Chemical industry Pharmaceutical industry Food industry Approvals BAM FDA conformity EN 1935:2004 in...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % PTFE Fiber with Unique Blocking Agent Characteristics In applications with high pressure or vacuum, die formed bullrings of S4 (no food approval) are recommended Very low coefficient of friction and displays low stem/spindle frictions Long lifetime No ageing Minimized maintenance and readjustment Operating range Pressure [p max]: 25 bar, Velocity [v max]: 2 m/s Pressure [p max]: 250 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.65 g/cm³ Main application Valves Fittings Gate valves Flaps Plunger Door and lid seals Suitable for Pulp and paper industry Chemical industry General Industry Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg of packing of the following cross-sections is...

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

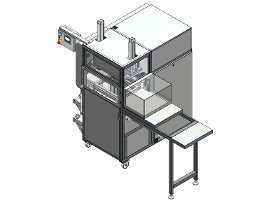

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

CBG COMPOSITES GMBH

Germany

High-temperature vacuum-formed products made from biosoluble ceramic fibres are lightweight and solid parts or structural elements that can be used at temperatures up to 1.400 °C in air and in aggressive environments, including direct contact with liquid metals. — 100% biosoluble — high temperature resistance — low thermal conductivity — high chemical resistance * — low weight — good tear resistance — high flexibility — easy processing — complicated geometries can be produced — recyclable * to achieve higher acid resistance, a special coating is required. Available from manufacturer. Application: Burner plant components, crucibles, thermocouple housings, coupling devices in continuous casting plants, channel elements of metal troughs, inlet device in the melting of non-ferrous and ferrous metals, gasket in aluminium foundries, gaskets in blast furnaces, expansion joints, pipe insulation, catalyst insulation, repair work in the high temperature range.

Request for a quote

CBG COMPOSITES GMBH

Germany

High-temperature vacuum-formed products made from biosoluble ceramic fibres are lightweight and strong parts or structural elements that can be used at temperatures up to 1 .600 °C in air and in aggressive environments, including direct contact with liquid metals. — 100% natural — biosoluble — high thermal shock resistance — low thermal conductivity — high chemical resistance * — recyclable — low weight — good tear resistance — high flexibility — easy processing — harmless to health — complicated geometries can be produced * A special coating is required to achieve high acid resistance. Available from manufacturer. Fields of application: gaskets, crucibles, thermocouple housings, coupling devices in continuous casting plants, expansion joints, convex and flat gaskets in blast furnaces, channel elements of metal troughs, inlet device in the melting of non-ferrous and ferrous metals.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quoteResults for

Vacuum forming - Import exportNumber of results

12 ProductsCountries

Company type