- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- turnkey

Results for

Turnkey - Import export

SAMAG MACHINE TOOLS GMBH

Germany

PROCESS-RELIABLE SOLUTIONS FOR HIGH VOLUMES – EFFICIENT PRODUCTION WITH MINIMAL UNIT COSTS. The automotive industry is the ultimate challenge with its range of parts and performance indicators. Only innovative machine concepts are solutions that ensure efficiency in the process. Companies from the vehicle and supplier industries worldwide therefore successfully use SAMAG machining centers and production machines, including turnkey solutions. High precision, reliability, automation and cost optimization are among the key automotive requirements.

Request for a quote

VIDEODESK STUDIO LIGHTBOARD

Germany

Complete set of 4K Transparent board 110x174 cm, with RGB LED backlighting of glass and LED backlighting of speaker, 4K quality video camera, sound system (looping radio system, connecting cable, sound card, chargers, headphones), 2 screens for speaker and 4K operator monitor, 6 LED lights for lighting speaker and backgrounds, backgrounds black, color paper and chromakey, teleprompter on the basis of a tablet

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

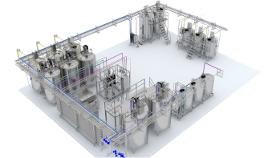

FILLTECH GMBH

Germany

Costumer specific systems and Turnkey-Solutions Filltech designs, produces and implements fully automated gas filling solutions for the medical, consumer, industrial and special gas industry. All fully automated filling systems have been developed in close cooperation with the customer to ensure the best possible solution for their specific needs. Advantages Design of fully or semi-automated filling stations (in-house or in strong cooperation with your engineering team) One-stop-station for all necessary handling: emptying, cleaning, filling, weighing, leakage control, sealing and shielding In-house production of all filling stations Implementation at your premises Education at your premises 24/7 Back-up support available General capacity: 1000 CO 2 cylinders/hour IT-integration with your systems Track & Trace Ergonomic approach Conversions to AD2000 DIN/ISO 9001 ISO 22000 Module AI in accordance with RL 97/23/EG PED The following products might also be of interest to you: CO 2

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple product viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WESSEL-UMWELTTECHNIK GMBH

Germany

Bio scrubbers are systems for the biological cleaning of exhaust air and exhaust gases and thus for the reduction of odours and polluting emissions. In this process, air polluted with a wide variety of pollutants is cleaned with the aid of a washing liquid which is loaded with microorganisms and biocatalysts (various enzymes) taken from nature. The bio scrubbers from WesselUmwelttechnik work almost without wastewater and are therefore very sustainable, regardless of the nature of the exhaust air. The basic requirement, however, is that the ingredients are watersoluble and bioavailable. WesselUmwelttechnik supplies turnkey plants like the Wessel BIOCATScrubbers in single and multistage construction.

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

Make SCHULZ your choice for both building and brewing: Every detail of your brewery project is in good hands with our outstanding team. Whether it’s the building design, part manufacturing, or installation, every detail is ironed out according to the customer’s wishes. In our mind, success lies not only in state-of-the-art brewing technology, but in the ongoing dialogue with the client as well. Dimensioning (layout) and delivery of: Malt milling equipment, brewhouses, energy-saving systems (e.g. vapor condenser, vapor compressor, and Gentle-Boil System SchoKo 2.0), water tanks, wort cooling treatment, lactic acid plants, fermentation and storage tanks, yeast storage cellar incl. purely cultivated yeast, CIP systems, filtration, pressure tanks, keg and bottle filling equipment (in cooperation with reputable suppliers), consumption and waste figures, refrigeration systems, compressed air systems, power and heating supply.

Request for a quote

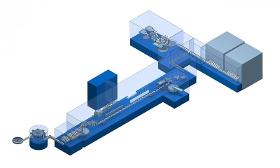

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quote

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Statistical In-Process-Control (IPC) Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Turnkey - Import exportNumber of results

14 ProductsCountries

Company type

Category

- Pharmaceutical industry - machinery and equipment (4)

- Advertising studios (1)

- Air purification - equipment and systems (1)

- Dairies - machinery and equipment (1)

- Food industry - machinery and equipment (1)

- Induction heating systems (1)

- Mechanical engineering - custom work (1)

- Pumps (1)

- Video production (1)

- Wine fermentation tanks (1)