- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- transfer lines

Results for

Transfer lines - Import export

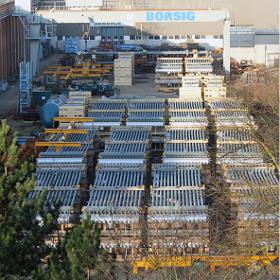

BORSIG GMBH

Germany

Transfer Line Exchangers (tunnelflow and linear quench coolers) from BORSIG are used in plants producing ethylene, an important starting material for plastics manufacturing. In these ethylene plants our transfer line exchangers are rapidly cooling down the so-called cracked gas in order to obtain the optimum yield of ethylene. BORSIG Transfer Line Exchangers are the result of more than 50 years experience and about 7,500 units have been supplied worldwide between 1965. BORSIG Process Heat Exchanger GmbH has developed two design types of quench coolers, reflecting the customer`s plant concept: 1. "Tunnelflow" transfer line exchangers (shell & tube design) 2. BORSIG "Linear" transfer line exchangers (double-pipe design)

Request for a quote

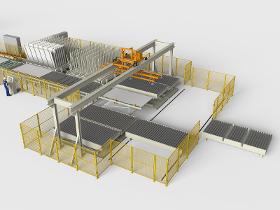

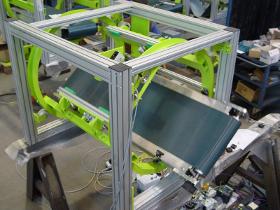

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

From semi-automated to fully automated - from simple to complex: As a manufacturer of special systems, we are specialized in assembly systems to develop according to customer requirements, so that innovative products can be created. We are industry-neutral, i.e. our systems are used in the most diverse industrial sectors. We have references in automotive, medical technology, e-mobility, renewable energies and aerospace. Here you can find a selection of the implemented assembly system types: - Robot solutions - Interlinked systems - Fully automated lines - Rotary transfer machines - Manual workstations - Hybrid systems An in-house development from our company is the VARIOMODUL®, which allows your system to be quickly adapted to dynamic market changes. Standardized modules, processes, handling technology and peripherals are used. For further information please refer to the corresponding download.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5106 combined the advantage of the GWE 5104 Servo-Insert Coupling with an easy installation. The clamping hubs in split hub design can be mounted lateral at the aligned shaft extensions. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5106 Servo-insert coupling with clamping hubs in split hub design Characteristics Hubs made of aluminum, from size 55 made of steel Standard elastomeric spider with 98° A...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

The GWE 5107 is a compact designed backlash-free Servo-Insert Coupling with an expanding clamp and a clamping hub. Due to the expanding clamp the GWE 5107 can used for examples in hollow shafts. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5107 Servo-insert couplings with clamping hubs and expanding clamps Characteristics Hubs made of aluminum Expanding mandrel and inner cone made of steel Elastomeric spider...

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

GERWAH's Servo-Insert Couplings from the production series 'GWE 5103.1' impress with their compact design. The compensating elements are slotted once and mounted by means of a clamping hub. GWE 5103.1 couplings are electrically insulating, installation-friendly and absolutely fail-safe. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying equipment Linear motion Measuring equipment and control technology Test rigs Series GWE 5103.1 Miniature servo-insert Coupling with clamping hubs and single...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RINGFEDER POWER TRANSMISSION GMBH

Germany

GWE 5102 miniature is a compact miniature coupling constituting the perfect solution for confined spaces or areas which are difficult to access. The element is connected to the shaft by means of radial set screws instead of a clamping hub. The coupling is available with elastomeric spiders of different degrees of shore hardness. But regardless of the chosen features: GWE 5102 miniature is always electrically insulating and vibration-damping. Backlash-free Servo-Insert Couplings are used in mechanical engineering, where shock absorption is requested and pluggable coupling solutions are applied. Special Features Backlash-free Pluggable Vibration damping Torques from 0,5 - 650 Nm Compensation of radial, axial and angular misalignment Electrically isolating Common Applications Encoder Precision drives Feed drives Grinding and milling spindles Machine tools Packing machines Robotics Transfer lines Multi-spindle heads Wood processing equipment Textile machinery Conveying...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

This is where the nished boards are sorted by quality and stacked for transport. Features, function The nished boards are transferred from the nishing line, centred, taken up by a suction carriage and placed in dierent stacks depending on the quality assigned in the nishing line. A horizontal transfer carriage picks the stack up and transfers it to a transfer stack. It can be removed by a forklift truck from here. Advantages The options also permit a top and bottom protection board to be put in place without this having an impact on plant performance.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

For assembling and connecting transfer lines Welding – major suitability certificate required Mechanical engineering Surface treatment Preassembly at FMS’ facilities including regulation and control systems On-site assembly

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quote

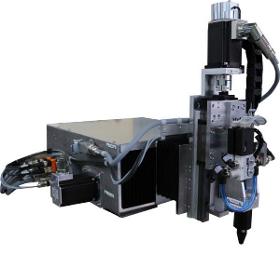

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES built-in impact units are suitable amongst others for marking applications on transfer lines, rotary tables or testing stations. Because of the big usable stroke workpieces with different heights can be marked without any adjusting.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES pneumo-hydraulic marking machines are suitable for applications that need big marking forces. They are available either as complete units with column or C-clamp rack or as built-in units for transfer lines and round cycle facility.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES numbering heads were used to mark consecutive numbering, serial or model-number on almost all materials like steel, cast iron, aluminum, plastic etc. The application area ranges from the single production up to the integration in automatic production or transfer lines. The numbering heads can be combined with each other and extended with type holders and steel types. Besides numbers, letters or special engravings are also available. All BORRIES products are assembled with the highest precision and quality standard. It guarantees a long life time and a high stability.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in unit 322 is a highly robust device for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. Together with a marking head and a controller this marker is integrated as a built-in unit in our special systems or by system producers for direct workpiece marking, e.g. in transfer lines, production machines or gauging and testing stations. The marking head is directly mounted underneath the coordinate unit. Marking areas 100 x 100 mm, 100 x 50 mm, 40 x 50 mm, 150 x 100 mm, 150 x 150 mm, 250 x 150 mm (X/Y) – other sizes possible.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The marking unit 315 is a very well protected and highly robust device designed for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. The set of a marking head and a controller is integrated as a built-in unit by system producers for direct workpiece marking e.g. in transfer lines, production machines or gauging and testing stations. The pneumatic (PN) or stepping motor (SM) adjustment unit allows to forward the marking unit to the workpiece even at places which are difficult to access. Marking unit for marking processes: scribe, stylus, dot marking and DataMatrix coding (ECC200)

Request for a quote

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The three axis of motion enable a high performance and an efficient design of the robot system. The central pick up table picks up a whole layer of glass from the pallet. The table pushes the layer on the discharge table in one operation which seperates the glasses and transfers them to the production line. Since the roTeg depalletizing robot DERO II works with clamping jaws, numerous package sizes can be processed without mechanical devices. In each depalletizing cycle the interlayers are also picked up by the glass layer and collected in a magazine. The movability of the robot construction on the x axis enables the handling of different production lines. While one discharge table is still filled with glasses and being emtied line by line the DERO II already takes the next layer and serves the second discharge table.

Request for a quoteResults for

Transfer lines - Import exportNumber of results

16 ProductsCountries

Company type