- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- torque motors

Results for

Torque motors - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

The DDA Direct Drive Motor is a rotary actuator that directly drives a rotary table with a motor without using any speed reducing mechanism such as a belt or reduction gears. Eliminating the speed reducing mechanism explains why high speed and excellent response can be attained with such a compact frame. The series includes models designed for high torque and high payload up to 90 or 270 kg. This makes it very easy, for example, to integrate rotary indexing tables in an automation system.

Request for a quote

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

CEDS DURADRIVE GMBH

Germany

CEDS torque motors offer you special advantages: Light and compact design Very high torques can be represented High speed constancy High positioning accuracy Low detent torque Low rated speed Big hollow shaft Very quiet Low inertia, therefore very dynamic Very high force density Long life span Torque motors are characterized by a very compact design in combination with a very high torque at low speed. A high force density in relation to the installation space and a low cogging torque are further points that a torque motor fulfills. CEDS DURADRIVE torque motors are designed to save space and have a high level of positioning accuracy. These motors are very often used instead of gear solutions and minimize wear and backlash during positioning.

Request for a quote

IGUS® GMBH

Germany

Planetary gears for igus® stepper motors NEMA 23, 23XL & 34 Increased motor torque Increased brake holding torque 2 installation sizes Reduction gearing of 3 & 5 available Typical applications:Packaging technology, general mechanical engineering, inspection technology/ camera travel drylin® E data sheet - Gearbox for stepper motors GEA-60-..._EN.pdf Planetary gears for igus® stepper motors NEMA 23, 23XL & 34 Increased motor torque Increased brake holding torque 2 installation sizes Reduction gearing of 3 & 5 available Typical applications:Packaging technology, general mechanical engineering, inspection technology/ camera travel

Request for a quote

IGUS® GMBH

Germany

Versatile choice due to the high torque and speed. This motor is the best choice for most applications with medium loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. The connector interface provides a high IP65 protection level (IP: International Protection). The higher the IP rating, the better the motor is protected from the ingress of dirt and water. The encoder sends signals from the motor to the motor control. The encoder verifies that the required linear motion has occurred precisely as required. Encoder = increased machine accuracy.

Request for a quote

IGUS® GMBH

Germany

This little motor has impressive torque and high RPMs. Reliable operation with quick movements of low loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. Motors with stranded wires are the least expensive and the most common stepper motors. The connecting wires for this type exit from the housing and will be connected with a JST connector. They are usually installed in machines and equipment that have an additional housing or are used in clean environments.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Dial Indicating Torque Screwdriver with mNm scale Tohnichi's MTD series torque screwdriver is suitable for inspection and tightening of very small screws, e.g. small torque motor shafts or the like. Torsion bar mechanism makes accurate measurement possible. With bi-directional scale plate, it can be used for both retightening and loosening torque testing methods. Memory pointer captures peak torque. Applicable for international use including the EU region. Compliant with calibration procedures of ISO 6789 Type I Class D. Key Features: - Bi-directional scale - Peak torque indication via Memory Pointer - Accuracy and calibration compliant to ISO 6789 type I class D - Bit insert #2 Tohnichi Shipping List: - Screwdriver MTD - Calibration Certificate (ISO/JIS) - Operating Manual - Special Bits Cross #0, Slotted 0.15x1, 0.2x1.5, 0.3x2 Options: - Alternatively with english units (ozf·in) available. Metric scale (gf·cm) on request.

Request for a quote

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Precise, reliable measurements of both static and dynamic torques in either direction can be made with this range of sensors. This opens a wide range of possible applications to the user. These torque sensors are standard equipment in a wide range of industrial automation, quality control and automotive components industry applications, as well as in laboratories. Typical applications: Screwing technology — Checking and adjusting bolting tools such as torque limiting wrenches, screwdrivers — Testing bolted connections Measuring the drag torque of motors and pumps — Frictional torques of gears, bearings and seals — Testing torsion springs — Adjusting equipment in the automobile industry (sunroof, power windows etc.) Strain gauges are mounted on the torsion shaft of the sensor element, itself made of steel, connected to form a full bridge.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quote

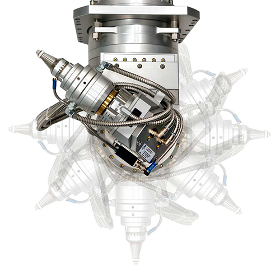

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

RSLD is our short cut for a laser head consisting of a total of 3 motorized axes for use in large-format laser machines in gantry design for the 3-dimensional laser cutting of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with low-absorption coating or alternatively glass optics. The use of an adaptive optics enables the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

RSD is our short name for a laser head consisting of a total of 2 motorized axes for use in large-format laser machines in gantry design for 3-dimensional laser cutting / laser welding of components. The horizontal main axis of the laser head permits endless movement, even during the rotary movement the axes below are permanently supplied with cooling water, process gases and all electrical signals. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

SD is our short cut for a laser head consisting of either the swivel axis only or in combination with a highly dynamic linear axis for laser processing of pipes. Suitable optics are used for the laser source used, either directly water-cooled metal mirrors with coatings of least absorption, or alternatively glass optics. The use of an adaptive optics optionally allows the freely programmable focus position for cutting and piercing. The exclusive use of torque motors reduces mechanically moving components and thus guarantees consistently high machining accuracy and best machining results over a long service life, against mechanical damage reliably protects our proven 3D collision protection. The clear aperture of the current laser swivel head SH35 is 35mm, the larger version SH60 is still available with a clear aperture of 60mm.

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

HONSEL-GROUP

Germany

Electric-hydraulic setting tool for stationary automated or hand-held processing of blind rivet nuts and studs. Perfect combination of high setting force, slim design and low weight. The narrow design allows a small centre distance for modular design. — Process monitoring DMSD 2G Displacement encoder with resolution 0.01 mm Sensor technology force measurement via hydraulic pressure — Hydraulic connection for pressure intensifier — Mechanical connection — Tolerance compensation Position offset 1.5 mm Angular misalignment 8° — Electric motor Monitoring of torque and rotationangle during spindle mounting and dismounting — Hydraulic hollow piston cylinder stroke 12 mm setting force up to 58 kN — Quick-change system For fast handling and low-maintenance operation Low tool costs by using DIN screws as mandrel (option)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WIGTEC FISCHEREDER KG

Germany

Traverse path: 1250 x 1250 x 870 A axle ± 140° C – axle 360° (endless) High precision machining centre in gantry construction All axles are double-equipped with motor and linear scales Rotary axles are driven by torque motors Zero point clamping system

Request for a quote

ETH-MESSTECHNIK GMBH

Germany

Miniature Metal Bellows Coupling axial pluggable, with collet clamps Backlash-free miniature metal bellows coupling with clamp hubs For shaft diameter from 3 – 25 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly with friction-locked clamp hubs Perfect bellows coupling for encoders, tachometers, potentiometers, servo drives, NC axis, stepper motors Torque range: 0,5 – 10 Nm Axial pluggable

Request for a quote

ETH-MESSTECHNIK GMBH

Germany

Miniature Metal Bellows Coupling with collet clamps Backlash-free miniature metal bellows coupling with clamp hubs For shaft diameters from 1 – 25mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly with friction-locked clamp hubs Perfect bellows coupling for encoders, tachometers, potentiometers, servo drives, NC axis, stepper motors Torque range: 0,1 – 10Nm

Request for a quote

STARRAG GMBH

Germany

Fewer rejects thanks to high concentricity and axial runout accuracies (< 2 μm)Wide manufacturing range thanks to precise and powerful table drive (torque motor)Increased productivity through complete machining in just one setup

Request for a quote

STARRAG GMBH

Germany

Fewer rejects thanks to high concentricity and axial runout accuracies (< 2 μm) Wide manufacturing range thanks to precise and powerful table drive (torque motor) Increased productivity through complete machining in just one setup

Request for a quote

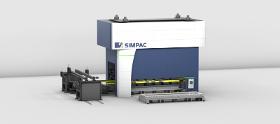

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 8,000 - 30,000 kN ● Part size: medium to large ● Slide kinematics: servo (freely programmable) ● Applications: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes thanks to the use of torque motors that deliver high torque even at low speeds ● Maximum production flexibility through free programmability of slide movement, (forming) speed and stroke lenths ● Significantly more output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

SIMPAC EUROPE GMBH

Germany

SIMPAC presses with servo direct drive stand for highly dynamic forming processes and offer maximum flexibility in the production. In combination with a high stiffness value of press body and drive, they deliver consistently high part quality. Overview: ● Press capacity: 3,000 - 10,000 kN ● Part size: small to medium ● Slide kinematics: servo (freely programmable) ● Application: stamping, cutting, bending, embossing, drawing, integration of subsequent processes Features and benefits: ● Dynamic processes through the use of torque motors that provide high torque even at low speeds ● Maximum production flexibility due to freely programmable slide movement, slide velocity and stroke length ● Significantly higher output compared to conventionally driven presses due to reversing pendulum movement of the slide ● Very solid, FEM-calculated and low stress annealed press body

Request for a quote

TQ SYSTEMS GMBH - PRODUKTBEREICHE

Germany

Flexible drive solutions through motors with RoboDrive technology Key functionalities High torque with compact design High power density through maximum copper fill factor Reduced power loss through optimized stator and rotor design Use as direct drive with reduced motor speed Highly precise controllability, positioning accuracy and dynamics High efficiency with compact design Modeled drive, tool-based optimization over the entire drive train Hollow shaft design

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Angle encoder modules from HEIDENHAIN are combinations of angle encoders and high-precision bearings that are optimally adjusted to each other. They are characterized by their high degree of measuring and bearing accuracy, their very high resolution, as well as optimum repeatability. The low starting torque permits smooth motions. SRP angle encoder modules are additionally equipped with an integrated torque motor. They therefore combine a motor, precision bearing and encoder with very high accuracy in one compact system. The torque motor with its very low detent torque enables extraordinarily smooth motion control. Neither disruptive detent torques nor radial forces impair the high guideway accuracy of the bearing. Thanks to their design as completely specifi ed and tested composite assemblies, handling and installation is very simple.

Request for a quote

FISCHER FORTUNA GMBH

Germany

and HSK-25 tool interface. To meet the ever growing demand for compact and process-reliable high-frequency spindles – for micro chipping applications in dental and medical technology, as well as in the fabrication of molds and tools – our experienced engineers have developed the SD4064 spindle. Compact design, resulting in less weight High-performance motor thanks to synchronous technology Consistent torque from 500 rpm. Motor feedback - SIN / COS sensor Maximum motor mount rigidity Highest possible concentricity <2µm Flange adaptor upon customer request Optional dilatation sensor Spindles are not sold on the Webshop, but spindle inquiries are accepted. Below on this page are listed the available accessories and peripherals.

Request for a quote

WATERGATES GMBH & CO. KG

Germany

Technical data In general The actuator is especially suitable for the operation of ball valves and butterfly valves with 90°-rotation angle. A waterresistant body with overload protection and a heating device against condensation water. Materials Carbon Steel, Aluminium Alloy, Bronze Body polyester coated Installation Vertical as the picture shows. All other installations only after request. Ambient temperature -20°C … +70°C Mounting pad DIN-ISO 5211 Standard voltages 24V DC (only up to NA028) 230V AC, 400V 3AC others on request Protection IP 67 ATEX-Protective class (Option) II 2G EEx d IIB T4 Cable entry 2 x M20x1,5 Protection devices 2 (OPEN/CLOSE) torque switches, Motor thermostat End stops 2 limit switches. Operating angle 90° ±5° Heater 20W Duty cycle 25 … 50% Standard equipment 2 additional limit switches, optical position indicator, manual override. Option Please refer to the data sheet The above information is intended for guidance only and the company reserves the right to change any data herein without prior notice!

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description Rotary Dividing Table with direct drive SKH-NC9/T - Construction: continuous NC table with direct drive - construction height: 420 mm - drive: water-cooled torque motor - max. table top speed: 250 RPM - table top: dia. 1,600 mm - table load "turn": 3,000 kg - table load "mill": 6,000 kg - permanent torque available at the rotary table (with water-cooling): approx. 2,500 Nm by n table=100 RPM aproxx. 1,700 Nm by n table=150 RPM

Request for a quoteResults for

Torque motors - Import exportNumber of results

38 ProductsCountries

Category

- Electric motors and parts (7)

- Electric motors - aC (4)

- Laser - cutting and welding machines (3)

- Machine tools, metal machining - parts and accessories (3)

- Measurement and control instruments (3)

- Metal industrial presses (2)

- Metal straightening machines (2)

- Sensors (2)

- Electric motors - dC (1)

- Automation - systems and equipment (1)

- Robotics (1)

- Clutches (1)

- Measurement - Equipment & Instruments (1)

- Tightening wrenches (1)

- Tools & Hardware (1)

- Vacuum cleaners - industrial (1)