- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thrust bearings

Results for

Thrust bearings - Import export

IGUS® GMBH

Germany

Thrust bearing / Spherical axial bearings from igus d1 [mm]: Mechanical properties The self-aligning spherical igubal ® thrust bearings are very easy-to-mount units, which help to compensate for errors and prevent misalignments. The thrust bearing housing pad is made of the impact-resistant, stiff, thermoplastic composite material igumid G. The standard thrust bearing washer is made of iglidur® W300. This combination provides particularly good gliding and wear properties in relative movements. Loads The load carrying capacity of the spherical igubal® thrust bearing is very high in normal ambient temperature. In particular cases the load carrying capacity of the axial bearings should be checked in a practical trial with high constant loads and at higher temperatures. Coefficients of surface friction and speeds Taking the radial loads into account, maximum surface speeds up to 0.5 m/s rotating can be attained. Installation The axial bearing pad is mounted flush and secured. The spherical washer glides loosely in the pad and is held by the shouldered shaft mounted on it. Delivery program As standard, the spherical igubal® axial bearings are supplied in sizes of 5 to 20 mm. For other dimensions, please contact us. Special features Simple assembly Compensation of misalignments Compensation of edge loads Very good gliding and wear properties, low installation space When to use it? When you want to save weight When freedom from corrosion is required When a bearing with good friction coefficients is sought When not to use? When very heavy loads act When constant temperatures of more than +80℃ occur When high rotary speeds must be implemented. Thrust bearing / Spherical axial bearings from igus d1 [mm]:

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LUTZ PUMPEN GMBH

Germany

The TMR series is a reliable magnetic drive pump that easily handles critical operating conditions due to its patented magnetic axial thrust compensation. * Drive via magnetic coupling with patented magnetic axial thrust compensation * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Due to "magnetic axial thrust balancing" the bearing system "R" is suitable for dry running * Motor and pump are mechanically separated * Connections with thread or flange

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

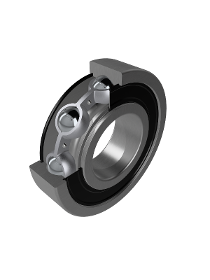

KIS deep groove ball bearings are characterised by their high load carrying capacity and speed stability. Depending on the requirements of your application, they are available in different variants and in both radial and axial design. Our single row deep groove ball bearings are available in open and sealed designs. Open bearings are maintenance-free, while sealed bearings offer better corrosion protection. Single row deep groove ball bearings can support both radial and axial forces. Our double row deep groove ball bearings feature a higher radial load carrying capacity. They are used when the radial load carrying capacity of single row deep groove ball bearings is not sufficient. Axial deep groove ball bearings are suitable for supporting particularly high axial loads. They are available in both single and double direction. Single direction thrust ball bearings can only support axial forces, while double direction thrust ball bearings can support both radial and axial forces.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

KFB-Clarfeld thrust ball bearings are manufactured as single and double direction models. Ball bearings of the series 511, 512, 513 and 514 are single sided, the models 522, 523 and 524 are double sided. Thrust ball bearings are composed of shaft washers, cage washers, and cage assemblies. The bearings are separable; cage assembly and bearing washers can therefore be fitted independently of each other. Both models tolerate high axial forces, however, they may not be radially stressed.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

IBK WIESEHAHN GMBH

Germany

Technical plastics for industry are a further speciality of IBK. We produce plastic parts to your specifications (ISO, CAD, drawing) for all temperature ranges and with specific chemical resistance. Whether unusual, complex or just simple forms – we turn, inject, saw, drill or mill, whatever you require. We supply semi-finished products as round bars, plates, pipes, rods, profiles or individual cuts, rolls, rollers or wheels with or without coating. Furthermore finished parts, such as protective systems for safety at the workplace in electronic applications. We process all types of plastic, from polyamide to hard PVC through to GRP/FRP. Semi-finished parts: Plates, Blocks, Full rods, Hollow rods, Pipes, Cut pieces Finished parts Cut and processed (turned, milled, drilled etc.) to drawing, sketch or sample, such as - Wheels, Rollers, Bearing bushes, Thrust rings, Bands, Sleeves, Strips

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description Workpiece support Indexing table unit 360x1° / no lifting off NC special indexing table SDV-NC3.5/3H and NC thrust bearing - Duplex-worm gear i=85 with i=5 with belt drive - Division 360x1° - with hydraulic locking, indexing table 1,350 Nm, incl. thrust bearing 2,050 Nm Special charateristics: - 3 channel media supply from below (device tensioning, release, blast air) - Media supply from top, Hirth-ring tensioning, release, sealing air, hydraulic clamping

Request for a quote

ODDESSE PUMPEN- UND MOTORENFABRIK GMBH

Germany

Submersible motors from oddesse are used as pump drive for applications with special requirements, such as in mining, utilisation of geothermal energy as well as in offshore and marine technology. EXECUTIONS - Three-phase asynchronous motors for 50 or 60 Hz and voltages up to 1,000 V - Water-filled motors with rewindable stators, dynamically balanced and with high resistance to thermal stress High-quality thrust bearings that operate in both rotation directions and possess a high load-bearing capacity - Water-lubricated radial bearings for a horizontal and vertical motor application - Windings for temperatures up to 80° C of the pumped medium available - Speed regulation between 30 and 60 Hz via frequency converter possible - High-quality materials for application in service, industrial and seawater PERFORMANCE RANGE (AT 50 HZ) Up to 45 kW/60 HP with 6" motors Up to 132 kW/175 HP with 8" motors Up to 220 kW/300 HP with 10" motors Up to 400 kW/550 HP with 12" motors

Request for a quoteResults for

Thrust bearings - Import exportNumber of results

13 ProductsCountries