- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- threaded flanges

Results for

Threaded flanges - Import export

ANTHERMO GMBH

Germany

Wide range of products available at short notice Our delivery program in the product group flanges (ANSI B 16.5) includes the following types: Welding Neck Flanges. Slip-on flanges Loose Flanges (Lap Joint Flanges) Blind Flanges and Socked Welding Flanges Threaded Flanges Special / drawing parts. Special competence for special materials We supply flanges in the dimensions ½ "to 24" in the pressure levels 150/300/600/900/1500/2500 lbs. Our special competence lies in the delivery of special materials. The following special materials are available: Carbon Steel A 350 LF2 Chrome-Moly Alloy A 182 F Chrome-Moly Alloy A 182 F11 Chrome-Moly Alloy A 182 F 22

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

IGUS® GMBH

Germany

igubal® flange bearing EFOM With 2 mounting holes igubal® flange bearing EFOM igubal® flange bearing EFSM With 4 mounting holes, dimensional series E igubal® flange bearing EFSM igubal® flange bearing KFSM-GT With 4 mounting holes, dimensional series K igubal® flange bearing KFSM-GT igubal® flange bearing EFOM HT Applicable up to 200°C,resistant to chemicals , with 2 mounting holes igubal® flange bearing EFOM HT igubal® flange bearing EFSM HT Applicable up to 200°C,resistant to chemicals , with 4 mounting holes igubal® flange bearing EFSM HT igubal® flange bearing with ball pins, male thread igubal® flange bearing with ball pins - male threads for direct connections igubal® flange bearing with ball pins, male thread igubal® flange bearing with ball pins, female thread igubal® flange bearing with ball pins, female threads for direct connections igubal® flange bearing with ball pins, female thread igubal® flange bearings were developed for the bearing of shaft extensions or shaft bushings. Like all igubal® products, they consist of an igumid G housing and an iglidur® W300 spherical ball. igubal® flange bearings correspond to the dimensional series E and are offered with 2 or 4 mounting holes. Features igubal® flange bearings were developed for the bearing of shaft ends or shaft bushings. Like all igubal® products, it consists of a housing made of igumid G and a spherical ball in iglidur® W300. igubal® flange bearings correspond to the dimensional series E and are offered with 2 or 4 mounting holes. Application area As the igubal® flange bearings are also suitable for dry operation, they are particularly considered for applications in which the installation site is difficult, in humid or wet environment, or with special demands on hygiene. Thus the igubal® flange bearings are used for instance in wash-brush controls, in facade sunscreen systems, in materials handling systems and in bakery equipment. igubal® flange bearing - Applications Installation According to type, igubal® flange bearing are designed for mounting with 2 or 4 holes. The 2-hole types are provided with oblong holes that enable a trouble-free readjustment. A precise alignment of the bearing housing is not required as the flange bearing automatically compensates for error. Delivery program For shafts, igubal® flange bearings with 2 and 4 mounting holes are available in standard dimensions of 5 to 50 mm. For delivery times and more dimensions, you may please contact us. When to use it? When chemical resistance is required When a low-cost alternative is desired When dirt-resistant bearings are needed When misalignments should be compensated When fully split components are needed When not to use? When temperatures above +200°C prevail When an integrated collar is required When dimensions over 50 mm are needed When rotation speeds in excess of 0.5 m/s should be implemented igubal® flange bearing EFOM With 2 mounting holes igubal® flange bearing EFOM igubal® flange bearing EFSM With 4 mounting holes, dimensional series E igubal® flange bearing EFSM igubal® flange bearing KFSM-GT With 4 mounting holes, dimensional series K igubal® flange bearing KFSM-GT igubal® flange bearing EFOM HT Applicable up to 200°C,resistant to chemicals , with 2 mounting holes igubal® flange bearing EFOM HT igubal® flange bearing EFSM HT Applicable up to 200°C,resistant to chemicals , with 4 mounting holes igubal® flange bearing EFSM HT igubal® flange bearing with ball pins, male thread igubal® flange bearing with ball pins - male threads for direct connections igubal® flange bearing with ball pins, male thread igubal® flange bearing with ball pins, female thread igubal® flange bearing with ball pins, female threads for direct connections igubal® flange bearing with ball pins, female thread

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

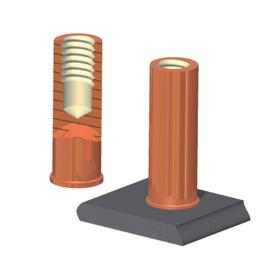

Universal tank caps and threaded flanges.

Request for a quote

BEKO TECHNOLOGIES GMBH

Germany

The energy costs of a compressed-air system are decisively influenced by the pressure drop occurring during compressed-air filtration. To maintain the required operating pressure, this pressure drop needs to be compensated by correspondingly higher compressor performance. The consequence: increased energy demand, premature wear of the compressor ... and therefore higher costs. The better solution: CLEARPOINT compressed-air filters by BEKO TECHNOLOGIES.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The TMR series is a reliable magnetic drive pump that easily handles critical operating conditions due to its patented magnetic axial thrust compensation. * Drive via magnetic coupling with patented magnetic axial thrust compensation * Typical applications: Acids, alkalis, acid and alkali mixtures, solvents, alkaline degreasing baths, electroplating baths, photographic chemicals Features & Advantages * Variable connection options * Compact dimensions, performance in line with requirements * Also for liquids with high density * Due to "magnetic axial thrust balancing" the bearing system "R" is suitable for dry running * Motor and pump are mechanically separated * Connections with thread or flange

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For mounting screwed connections, e.g. at combustion engines, threads on pipe fittings, flange joints and fittings of superheated steam lines, exhaust pipe and combustion chamber screwed connections, gas and oil burner mounting bolts To prevent burning together, seizing or rusting-on of screwed connections at water influence Suitable for brake systems of vehicles Advantages and benefits Excellently suited for preventing binding of threads exposed to high temperatures, corrosive environments and moisture Highly effective due to high level of pressure absorption Excellent corrosion protection Absolutely resistant to fresh water and sea water Extremely adhesive No classification according to (EG) No. 1272/2008 For best adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaning agent. Use a brush, spatula or similar

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of screw connections of high-strength steel subject to high temperatures, corrosive influences in chemically aggressive environments, e.g. on gas and steam turbines in power plants, combustion engines, threads on pipe fittings, flange joints and fittings in superheated steam lines, exhaust pipe and combustion chamber screwed connections etc. Parting lubrication of materials with a tendency to seize up, e.g. V2A, V4A and high-temperature steels Advantages and benefits Excellently suited for preventing seizing and binding Highly effective against corrosion affects Free of lead compounds, sulphides, chlorides and fluorides For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply paste evenly in sufficient amount onto head/nut support and thread or onto the sliding areas with brush, spatula, etc.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor is designed for both static and dynamic measurements on non-rotating parts. The 10mm diameter throughhole can be used to feed parts such as cables or Bowden cables through the sensor. The mounting flanges contain threaded holes and through-holes so that the sensor can be fitted at either end. With no rotating parts, this sensor needs no maintenance when used correctly. The modular design of this strain-gage sensor allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function. With the USB option, in addition to the voltage output, the measurement function is available via USB as well.

Request for a quote

BDSENSORS GMBH

Germany

The process pressure transmitter XMP i has been especially designed for the process industry and measures vacuum, gauge and absolute pressure ranges of gases, steam, fluids and dust up to 600 bar. Different process connections such as threads and flanges with an internal or flush welded diaphragm are available and can be combined with a cooling element for media temperatures up to 300°C. Features: — nominal pressure: 0 ... 400 mbar up to 0 ... 600 bar — accuracy: 0.1 % FSO — turn-down 1:10 — two chamber aluminium die cast case or stainless field housing — internal or flush welded diaphragm — HART®-communication — explosion protection: intrinsic safety (ia) Optional Features: — explosion protection flameproof equipment (d) — SIL2 -version according to IEC 61508 / IEC 61511 — integrated display and operating module — special materials as Hastelloy® and Tantalum

Request for a quote

BDSENSORS GMBH

Germany

The process pressure transmitter XMP ci measures the pressure of gases, steam, dust and fluids. The special-developed capacitive ceramic sensor for this transmitter has a high overpressure capability and excellent media stability. Several process connections e.g. thread or flange are available. The transmitter is as a standard equipped with HART®-communication, the customer can choose between a two chamber aluminum die cast case or a stainless field housing. Features: — nominal pressure: 0 ... 160 mbar up to 0 ... 20 bar — accuracy: 0.1 % FSO — turn-down 1:5 — two chamber aluminium die cast case or stainless field housing — internal or flush mounted capacitive ceramic sensor — HART®-communication — explosion protection: intrinsic safety (ia) — diaphragm ceramics Al2O3 (99.9 %) Optional Features: — explosion protection flameproof equipment (d) — with integrated display and operating module

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The DK37 M8 is a variable area (VA) flowmeter with electrical signal output and bargraph indication or mechanical indicator with two optional limit switches. The versatile all-metal measuring device is suitable for flow measurement of gases and liquids. Due to its sturdy design, the VA meter can be used at temperatures up to +200°C / +392°F or pressures up to 220 barg / 3190 psig. It is fitted with a needle valve as standard to accurately set the flow value. The DK37 M8 comes with vertical or horizontal process connections for NPT or G thread, flange adapters and many other connection options. To provide constant flow rates in case of variable inlet or outlet pressures, the VA meter is also available with flow regulators. It has approvals for hazardous areas and is suitable for use in Safety Instrumented Systems (SIS).

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

3-hole 90° Screw-in BSPP Threaded Flange WP-3-LK-G ▪ Working Pressure: 300 bar ▪ Ø LK: 26 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: ZnNi 4-hole 90° Screw-in BSPP Threaded Flange WP-LK-G ▪ Working Pressure: 250 bar ... 300 bar ▪ Ø LK:35 mm ... 55 mm ▪ Materials: S355J0or equivalent ▪ Surfaces: ZnNi 3-hole 90° Screw-in BSPP Threaded Flange(Aluminium) WP-3-LK-G-W50 ▪ Working Pressure: 180 bar ▪ Ø LK: 26 mm ... 51-56 mm ▪ Materials: Aluminium [EN AC-Al Si9Cu(Fe)] 4-hole 90° Screw-in BSPP Threaded Flange (Aluminium) WP-LK-G-W50 ▪ Working Pressure: 180 bar ▪ Ø LK : 30 mm ... 55 mm ▪ Materials: Aluminium [EN AC-Al Si9Cu(Fe)]

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

SAE Single-Part Screw-in BSPP Threaded Flange and Counterflange BFX-G / BAS-G ▪ 3000 PSI Standard Pressure Series (based on ISO 6162-1:2006): 1/2" (DN13) ... 5" (DN127) ▪ 6000 PSI High Pressure Series (based on ISO 6162-2:206): 1/2" (DN13) ... 2" (DN51) ▪ Materials: S355J0 equivalent, Stainless Steel 1.4404 on request (W5) ▪ Surfaces: blank, oiled SAE Single-Part Screw-in NPT Threaded Flange and Counterflange BFX-N / BAS-N ▪ 3000 PSI Standard Pressure Series (based on ISO 6162-1:2006): 1/2" (DN13) ... 5" (DN127) ▪ 6000 PSI High Pressure Series (based on ISO 6162-2:2006): 1/2" (DN13) ... 2" (DN51) ▪ Materials: S355J0 or equivalent, Stainless Steel 1.4404 on request (W5) ▪ Surfaces: blank, oiled SAE Single-Part Screw-in UN Threaded Flange BFX-U ▪ 3000 PSI Standard Pressure Series (based on ISO 6162-1:2006): 1/2" (DN13) ... 1-1/2" (DN38) ▪ 6000 PSI High Pressure Series (based on ISO 6162-2:2006): 1/2" (DN13) ... 1-1/2" (DN38) ▪ Materials: S355J0or equivalent, Stainless Steel...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

4-hole Screw-in BSPP Threaded Flange (Flat Style) GP-FL-LK-G ▪ Working Pressure: 180 bar ... 250 bar ▪ Ø LK: 30 mm ... 72,5 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: CrVI-free 4-hole Butt Weld Flange GP-LK...-ST.../...#K ▪ Working Pressure: 250 bar ▪ Ø LK: 30 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: blank, oiled 4-hole Fitting Flange with BSP 60° Cone Connector (acc. to BS 5200) GP-LK...-AG...#K ▪ Working Pressure 250 bar ▪ Ø LK: 30 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: CrVI-free 4-hole Screw-in BSPP Threaded Flange GP-LK...-G...#K ▪ Working Pressure: 250 bar ▪ Ø LK: 30 mm ... 56 mm ▪ Materials: S355J0 or equivalent ▪ Surfaces: CrVI-free

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Glass tube level indicator for operating pressures up to 25 bar. Made of high Quality stainless steel 1.4571 (AISI316Ti) with flange or male threaded connection. Application: For visual observation of fluid levels in vessels, boilers and silos.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF provides a complete range of Spin-On filters which can be used either as suction filters or as return line filters for low pressure applications. The various ranges meet international standards. The corresponding STAUFF Filter Elements are available from stock. Clogging Indicators (available as an option) ▪ Visual clogging indicator with coloured segments ▪ Electrical clogging switch ▪ Other types available on request Constructions ▪ In-line Spin-On filter head ▪ In-line Double Spin-On filter head ▪ Tank Top Spin-On filter head Operating Pressure ▪ Max. 14 bar / 200 PSI Nominal Flow Rate ▪ Max. 460 l/min / 120 US GPM Connections ▪ Option of BSP, NPT, SAE flange or SAE thread, others on request Material ▪ Filter head: Aluminium Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SFA are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 160 bar / 2.320 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ Medium pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Low weight and compact design Operating Pressure ▪ Max. 160 bar / 2.320 PSI Nominal Flow Rate ▪ Max. 240 l/min / 70 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO 6162-1) Materials ▪ Filter head: Cast...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 420 bar / 6.000 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 420 bar / 6.000 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO...

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Technical specifications • inner threads G1/4” ISO 228, flange DN 10 PN 40, sterile screw joints according toDIN 405 PN 16 • accuracy ± 0,1 kg/m³ • reproducibility 0,05 kg/m³ • operating temperature according to design -40°Cto +150°C • according to design admitted for custody transfer Accessoires • electronical transmitter • preamplifire • strainer • gas separator • processing peripherals

Request for a quote

DALMINEX GMBH

Germany

Installation piece for clean drinking water

Request for a quote

CL MACHINERY GMBH

Germany

The VK900 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present NO LUBRICATION required. No grease point! Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is...

CL MACHINERY GMBH

Germany

The VK138 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present Easily maintained with one lubrication point Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is.

EM-TECHNIK GMBH

Germany

3F fittings include a large number of unions such as nipples, unions, reducers and flanges in the many different variants with the familiar wide range of materials. • Nipples: with male threads • Unions: with female threads • Reducers: with different male and female threads and combinations of different thread sizes • Flanges: are used for detachable connection of pipes

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The piping system consists of high-grade NiroSan® press fittings with an EPDM (=ethylene propylene dien rubber) moulded sealing ring and NiroSan® stainless steel system pipes according to EN 10312. All NiroSan® press fittings are made from the premium stainless steel type 1.4404 / AISI 316L (for pressing components) and 1.4408 (for precision cast threaded stainless steel components). The material 1.4404 contains at least 2.3 % molybdenum, yet less carbon than the conventional type 1.4401. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® press system and its components are certified in accordance with the rules and regulations of all important European certification bodies.

Request for a quoteResults for

Threaded flanges - Import exportNumber of results

38 ProductsCountries

Category

- Pipe and tube fittings - ferrous metal (6)

- Plumbing, domestic (3)

- Measurement and regulation equipment and instruments - pressure (2)

- Silicones (2)

- Flanges (1)

- Air treatment - equipment and systems (1)

- Air-conditioning systems, vehicles (1)

- Centrifugal pumps (1)

- Flowmeters (1)

- Gas filters (1)

- Plastics - industrial machinery and equipment (1)

- Pumps (1)

- Reducers (1)

- Sensors (1)