- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermoplastic

Results for

Thermoplastic - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

Rubber-to-metal bonding Our adhesive build-up provides strong bonding between our metal carrier and your rubber. With our know-how, we are able to bond a wide variety of compounds such as NBR, CR, EPDM, SBR etc. for you. Plastic-to-metal bonding Whether PC (polycarbonate), PVC (polyvinyl chloride), ABS (acrylonitrile-butadiene-styrene), CAB (cellulose acetobutryate), PP (polypropylene), TPU (thermoplastic polyurethane), PA (polyamide) and polyolefinic plastics or other thermoplastics as well as duroplastics - we ensure that you achieve optimum adhesion between the plastic and our metal carrier.

Request for a quote

SPIROL

Germany

Heat / Ultrasonic Inserts are designed for post-mould installation in thermoplastics. Heat and ultrasonic installation yield outstanding performance results. SPIROL offers several different series of Heat/Ultrasonic Inserts available in a long and short version of each thread size. Long lengths maximize torque and pull-out resistance, while short lengths are good for less stringent requirements at lower cost and shorter installation times. Some styles are available with or without a head. The head provides bearing surface for the mating component that also prevents jack-out (or when used in reverse, can prevent pull through). However, adding a head results in additional cost raw material of a larger diameter is required to create the head. Some non-headed Inserts are symmetrical – thus eliminating the need to orient the Insert prior to installation.

Request for a quote

POLYNEO GMBH

Germany

The segment Performance Additives was established with the intention of offering our customers from the plastics industry an extensive and exclusive product portfolio. This product portfolio comprises a wide range of high-performance additives for various plastics. Fine-tuned to individual customer needs we deliver different additives, catalysts und colorants to PET producers.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

At OptiMel, you get everything from a single source to optimally use low pressure molding technology for high-quality electronics encapsulation. Thermoplastic hot melts are used as encapsulation material. Due to their range of properties, amorphous thermoplastic polyamide granules are predominantly used in low pressure molding. Thermoplastic polyolefins are also available for special applications, which are used whenever sufficient adhesion cannot be achieved with the preferred polyamides on the substrates used (e.g. cross-linked polyethylene). Due to different raw material combinations, the range of properties of these hot melt granules varies in terms of mechanical strength, operating temperatures and resistance to various media. The hot melt molding materials combine a viscosity spectrum that is favorable for the low-pressure process with a wide operating temperature range (-50 / + 150°C) and, in some cases, very good adhesive properties. Depending on the material

Request for a quote

KCD KUNSTSTOFFE, ADDITIVE UND BERATUNG GMBH

Germany

chemical blowing agents, microsphere masterbatches, lubricants, demoulding aids, UV stabilisation and more

Request for a quote

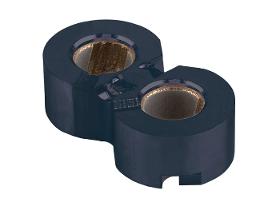

GLT BEARINGS GMBH

Germany

Thermoplastic all-plastic plain bearing | Maintenance-free COM-KU®/X is a self-lubricating and maintenance-free plastic plain bearing made of a high-quality plastic compound with the best sliding properties. Excellent tribological properties, especially for dry running. For technical details, please visit the product page on our website!

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

PT screws for thermoplastics: Thread rolling screws for direct screwing into plastics, Thread 30° or 60° KTG screws for thermoplastics: Single-start or double-start thread (high, low) Thread rolling screws are extruded for larger batch sizes and turned for small batch sizes (Turned parts for direct screwing) High tensile and highly stressable connection of thermoplastics with considerably longer life endurance Thread rolling without chips and loss of material Minimum radial tension, large thread coverage Process-reliable due to torsion strength Shorter and slimmer screws are possible. Materials: Steel, case-hardened Quenched and tempered steel 1.5523 tempered to 1000 +200 N/mm², high-grade steel 1.4567, other materials on request Length: 3 – 160 mm (at lengths from 60 mm only partial thread lengths 4 x d are possible) Thread diameter: 1.6 – 10 mm Special dimensions on request Batch sizes: Standard ex-stores Special screws from 30,000 pieces

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Optimel is your reliable partner for solutions for encapsulating electrical and electronic assemblies. The innovative Low Pressure Moulding (LPM) technology offers optimal protection against external influences such as moisture, dust and vibrations, thus ensuring the longevity and reliability of your products. The Low Pressure Moulding process or hotmelt moulding process originated in the sealing of cable harnesses in the automotive industry - today it is used in many areas for the protection of electrical and electronic components. At 5-40 bar (in individual cases up to max. 60 bar), processing takes place at a much lower pressure than in the classic hotmelt injection moulding process. This makes it easy to directly encapsulate even sensitive components such as circuit boards, sensors, etc. The cycle times are limited to pure encapsulation

Request for a quote

ROLKO KOHLGRÜBER GMBH

Germany

We offer quality slip rollers, keel rollers, rolls, wheels among other products for the boat trailer industry. Our products are certified and tested according to the latest European norms and quality standards. More information about our products and services can be found in our catalogues. Do you have questions about our products or do you want to request a quote? Please contact us. We have the right accessory for your boat trailer!

Request for a quote

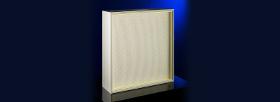

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

highperformance filter media with spacers of thermoplastic adhesives scan test analogous to DIN EN 1822 anodised aluminium profile continuous foam gasket bothsided grid protection selfsupporting media pack with optimised pleating geometry low pressure drop reduction of energy costs longlife cycles

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

highquality microfibre paper with spacers of thermoplastic adhesives particletight frame compound MDFframe, anodised aluminium profile or galvanised sheetsteel frame flat profile gasket selfsupporting media pack with optimised pleating geometry mounting independent of position enables easy installation

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

ProTec offers complete production systems for manufacturing long-fiber reinforced thermoplastics (LFT) in pellet form and as UD tapes (unidirectionally reinforced tapes) as well as impregnated fiber strands and profiles. The system works extremely flexibly and is designed for variable formulations and high throughputs at a production speed of 50 m/min. We deliver an LFT system design customized to meet the respective customer requirements, all from an single source – from material development, to testing and commissioning on location at the customer‘s premises.

Request for a quote

JOST CHEMICALS GMBH

Germany

Power Jet dissolves pollutions like: oils, greases, resins, silicon, residues of anti-corrosion agents, colorbatches, etc. Power Jet dissolves nearly all kinds of label adhesives. It evaporates without residues.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JOST CHEMICALS GMBH

Germany

fluid 015 dissolves pollutions like: oils, greases, resins, silicon, residues of anti-corrosion agents, colorbatches and tough stains like baked-on polymer residues. It evaporates very slow, but without residues.

Request for a quote

JOST CHEMICALS GMBH

Germany

fluid 040 is an NSF- M1 registred, silicone- and solvent-free, release agent. The M1 classification is the highest approval by NSF for release agents, similar to H1 for lubricants and anti-corrosives. fluid 040 can be used for all types of thermoplastic and thermoset casting resins, but especially for plastics which are sensitive to tension cracks. The maximum operating temperature of fluid 040 is 170°C.

Request for a quote

JOST CHEMICALS GMBH

Germany

fluid 010 dissolves pollutions like: oils, greases, resins, silicon, residues of anti-corrosion agents, colorbatches, etc. It evaporates without residues.

Request for a quote

JOST CHEMICALS GMBH

Germany

fluid 050/H1 dissolves pollutions like: oils, greases, resins, silicon, residues of anti-corrosion agents, colorbatches, etc. It evaporates without residues. Fluid 050/H1 can be used fast evaporating lubricant during the assembly of rubber parts.

Request for a quote

JOST CHEMICALS GMBH

Germany

HMC 180 is a cleaner for high tempered molds (above 60°C up to 180°C). Tenacious stains like baked-on residues, decomposed polymers and other contaminations can be removed easily. HMC 180 does not evaporate. To remove the dissolved residues a post-treatment with a quick cleaner (e.g.: fluid 010) is necessary.

Request for a quote

JOST CHEMICALS GMBH

Germany

Mold Cleaner #1 dissolves pollutions like: oils, greases, waxes and resins, even cured ones. Mold Cleaner #1 will remove the sealer form mold surfaces. Mold Cleaner #1 does not evaporate. Residues have to be cleansed with a quick cleaner (e.g.: fluid 010, Cleaner ES).

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Standard castor with thermoplastic rubber wheel - polypropylene wheel body with ball bearing - grey thermoplastic rubber tread, approx. 85° shore A - with thread guards to protect the ball bearing from dust and dirt - standard steel sheet housing, galvanized Torwegge‘s standard housings are made from deep-drawn, galvanized steel sheet. The solid-riveted, double ball bearing in the slewing ring delivers an advantageous price-performance ratio when used for hand-held logistics applications. Castors in standard housing are commonly used by a variety of sectors in transport racks. They can carry a max. load of 1,200 kg at 4 km/h. Thermoplastic (TPE) has a higher load capacity than rubber. These grey tires minimize the impact on your fl oors, providing a comfortable ride without leaving traces. Some contact discoloration may result from the oil-bearing material when the tires are left motionless for longer periods on sensitive floors.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

Smooth running polyurethane castor with polyurethane wheel - polypropylene wheel body with ball bearing - grey thermoplastic rubber tread, approx. 85° shore A - with thread guards to protect the ball bearing from dust and dirt Our apparatus castors are ideal for areas demanding low installation heights. Their slim design and high-grade materials help them to meet the demanding requirements that manufacturers have for shop equipment, medical equipment, display stands, office and household furniture usage. There are numerous mounting methods available so that these castors can be attached to a wide variety of equipment. Thermoplastic (TPE) has a higher load capacity than rubber. These grey tires minimize the impact on your floors, providing a comfortable ride without leaving traces. Some contact discoloration may result from the oil-bearing material when the tires are left motionless for longer periods on sensitive floors.

Request for a quote

HEXPOL TPE GMBH

Germany

Thermoplastic Vulcanisate or TPV compounds are high performance materials designed for demanding and dynamic applications. They are composed of a highly vulcanised rubber phase dispersed throughout a thermoplastic matrix and combine the processing ease, efficiency and recyclability of a thermoplastic with the improved flexibility, low compression set and resistance to aggressive fluids of a vulcanised rubber. This combination makes TPV’s ideal for variety of applications in several markets such as automotive, construction and appliances. Our Dryflex V range offers: A wide range of hardness’ Grades that can be processed by injection moulding, extrusion, blow moulding and thermoforming Service temperatures of -60°C to 135°C Improved resistance to aggressive fluids such as oils, acids, bases and aqueous solutions Low compression set Low flex fatigue Lightweight parts Design flexibility Recyclability Excellent weathering and environmental resistance Download Dryflex V - Thermoplastic

Request for a quoteResults for

Thermoplastic - Import exportNumber of results

28 ProductsCountries

Company type

Category

- Plain bearings (3)

- Filtering equipment and supplies (2)

- Potting equipment (2)

- Additives for plastics industry (1)

- Screws (1)

- Bearings - ball, needle and roller (1)

- Boat trailers (1)

- Castors, swivelling (1)

- Chemical catalysts (1)

- Metal industrial presses (1)

- Plastics - machines and material for industry (1)

- Screw cutting - steels and metals (1)

- Steels and metals - surface treatment and coating (1)

- Wheels, castors and rollers - rubber (1)