- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermoplastic processing

Results for

Thermoplastic processing - Import export

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

With our modern lathes and milling machines we can process thermoplastics according to the highest quality standards. We are using 3-axis as well as 5-axis milling machines. Example for our processing options: 3-axis machining up to a thickness of 80 mm and 1500 x 1000 mm format 5-axis machining up to a thickness of 700 mm and 2500 x 3000 mm format We manufacture according to provided drawings and CAD-data. Our programming stations are equipped with the latest CAD-CAM systems. Direct communication between job preparation and CNC work ensure a smooth process.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Occasionally also these terms are used for cartridge heates: heating cartridge, insertion heaters, spiral cartridge heaters. As a rule cartridge heaters consist of a cylindrical stainless steel tube and thus provide a high corrosion prevention. There is a heating wire inside which is wound onto a ceramic core. The number of coils varies depending on the power. In order to avoid a short-circuit, the cartridge heater is filled with magnesium oxide and compressed afterwards. Highly compacted they reach a surface watt density of up to 50 W/cm² and withstand highest stress. In the plastics industry cartridge heaters are used in hot runners in order to temper thermoplasts during injection moulding processes. Other areas of applications for process heat are e. g. packaging, diecasting or continuous casting in which zinc or aluminium are processed. Further applications are to be found in mechanical as well as medical and laboratory engineering.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

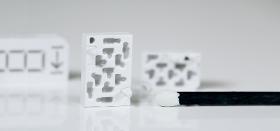

We accompany you with our design and development from the idea to series production! We process all common thermoplastics for you. Besides polyurethane, these are mainly: PE (polyethylene), PA (polyamide), PP (polypropylene), POM, ASA, TPU, PP, TPE as well as glass fiber reinforced plastics. Advantages of the injection molding process are low unit costs with high batch sizes. Before an injection mold is ordered, we build view samples for you as laser-sintered elements or by means of 3D printing. In this way, the desired part can already be viewed without having to spend a lot of money. Our machines inject molded parts from 5 to 6000 grams.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

When it comes to sophisticated plastic injection molding, we are completely in our element. We process all common thermoplastics, from standard to high-performance plastics. A fully automated production with handling systems for part removal and QA tests guarantees an economic production of your parts. We also have experience with the overmolding of various inserts such as threaded bushings, electronic contacts, circuit boards and much more. This and much more are the reasons why we are a reliable partner for almost all industries: Automotive industry aerospace industry Mechanical engineering Medical technology Construction industry Electrical engineering Jewelry and watch industry Furniture industry

Request for a quote

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to three components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JOST CHEMICALS GMBH

Germany

HMC 180 is a cleaner for high tempered molds (above 60°C up to 180°C). Tenacious stains like baked-on residues, decomposed polymers and other contaminations can be removed easily. HMC 180 does not evaporate. To remove the dissolved residues a post-treatment with a quick cleaner (e.g.: fluid 010) is necessary.

Request for a quote

JOST CHEMICALS GMBH

Germany

Power Jet dissolves pollutions like: oils, greases, resins, silicon, residues of anti-corrosion agents, colorbatches, etc. Power Jet dissolves nearly all kinds of label adhesives. It evaporates without residues.

Request for a quote

JOST CHEMICALS GMBH

Germany

fluid 040 is an NSF- M1 registred, silicone- and solvent-free, release agent. The M1 classification is the highest approval by NSF for release agents, similar to H1 for lubricants and anti-corrosives. fluid 040 can be used for all types of thermoplastic and thermoset casting resins, but especially for plastics which are sensitive to tension cracks. The maximum operating temperature of fluid 040 is 170°C.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Pioneering partnerships: Networking in our industry Siempelkamp actively contributes to the development of the industrial use of composite components with funding projects, cooperations with universities and industry partners as well as memberships in associations. Current R&D topics are for example: the manufacture of large-area structural components for the aerospace industry the integral construction approach, which combines several functions in one componen the further development of thermoplast forming for the industrial process the production of hybrid components made of ber reinforced plastic and metal for the automotive industry Through our active cooperation in associations, we are shaping the future of composite production. As a part of the competence network CFK Valley e.V., we contribute with our experience to the construction of presses for the practical application of ber composite and other lightweight construction technologies in the aircraft and automotive industry.

Request for a quote

HEXPOL TPE GMBH

Germany

Thermoplastic Vulcanisate or TPV compounds are high performance materials designed for demanding and dynamic applications. They are composed of a highly vulcanised rubber phase dispersed throughout a thermoplastic matrix and combine the processing ease, efficiency and recyclability of a thermoplastic with the improved flexibility, low compression set and resistance to aggressive fluids of a vulcanised rubber. This combination makes TPV’s ideal for variety of applications in several markets such as automotive, construction and appliances. Our Dryflex V range offers: A wide range of hardness’ Grades that can be processed by injection moulding, extrusion, blow moulding and thermoforming Service temperatures of -60°C to 135°C Improved resistance to aggressive fluids such as oils, acids, bases and aqueous solutions Low compression set Low flex fatigue Lightweight parts Design flexibility Recyclability Excellent weathering and environmental resistance Download Dryflex V - Thermoplastic

Request for a quote

HEUTE + COMP. GMBH + CO

Germany

Coatings made of PFA and PVDF fluorine-based thermoplastics provide safe protection against corrosion even on exposure to aggressive media. Because its molecular structure resembles that of PTFE, PFA is almost universally resistant to chemicals. Other special features of PFA linings are their wide range of operating temperatures and easy cleaning due to the material’s non-adhesive nature. In many applications, this makes it possible to replace stainless steel with a raw material which is not only much more economical but also easier to process. Because coatings are applied in a thermoplastic transfer-moulding process, it is necessary to account for certain design aspects which our team will gladly discuss with you in advance.

Request for a quoteResults for

Thermoplastic processing - Import exportNumber of results

12 ProductsCountries

Company type