- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal labels

Results for

Thermal labels - Import export

BIZERBA SE & CO. KG

Germany

Whether as a Windows® printer or part of a system network, the robust, stainless steel GLP-58 thermal printer impresses with its fast, reliable handling and multifunctionality. In combination with a range of Bizerba labeling systems, checkweighers and industrial terminals, it offers a wide variety of potential applications - both in manual labeling and statistical work. The label printer GLP 58-K on the ST terminal allows printing of up to three barcodes. It is possible to use not only standardized printing images but also custom layouts. The Windows® printer driver can be used to print out labels created using Windows® applications and the Bizerba Label Designer (BLD).

Request for a quote

BIZERBA SE & CO. KG

Germany

Industrial Barcode Label Printer with Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The Industrial Barcode Label Printer with Thermal direct and thermal transfer printer packed with more features, more convenience, and more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product for labelling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today and tomorrow's requirements. Future proof your business. The GLPmaxx Industrial Barcode Label Printer can be used as a label printer for product labelling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels....

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PDL model series for labeling Petri dishes from our special machine construction provides filled and sealed Petri dishes with a serialized DMC label in the minimum tolerance range at an output of 130 products/min. The system combines mechanical engineering, label material and thermal transfer printer. The Petri dishes from the previous filling/capping line are fed to the labeling system. By means of a clock star, the system transports the products through the various stations, such as labeling, the press-on unit and DMC inspection, where the grading (quality control) of the data matrix code takes place at the same time. In case of insufficient quality of the barcode, the product is ejected. By using our label dispenser RAPID SM we guarantee an accuracy of +-0.2 mm at a labeling speed of 60 m/min while maintaining the product quality. The signals are switched directly into the stepper motor card developed by us.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This powerful HSF friction feeder is the optimal solution when empty folding boxes have to be marked with variable data offline from the production line. The modular design of the system enables an easy integration of the desired marking technology. The HSF separates the folding boxes from the stack in the infeed magazine. The cartons are guided to the printing station by two parallel running belt conveyors. Print information could be e.g. serialisation data in the form of bar codes or data matrix codes and text. Depending on requirements, thermal inkjet, laser coders or label print- and apply systems can be used (also in combination). The printed data is inspected and verified by an integrated vision system. The b+b Linemanager recognized all 21CFR Part 11 data for each serial number and is able to report this back to the Siteserver system (e.g. b+b Siteserver).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This workstation enables the manual serialisation of drug packages and their aggregation into shipping cases. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system as it passes by and then manually placed in a shipping carton. As soon as it is filled, the downstream thermal transfer label printer creates an individual serialisation label. The correct print data and print quality are permanently monitored by a vision system. The operator places the medicine products to be serialized on a reference edge at the infeed. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product stops at a certain position marked by red LEDs. The removal of the rejected product must be confirmed by pressing a button on the HMI.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVEXX SOLUTIONS GMBH

Germany

The XLP 50x Label Printer series is the perfect print solution for medium label volume applications, available in 4 and 6 inch print width. lt can be used with thermal transfer or thermal direct technology and prints high quality barcodes, fonts, and graphics on a large variety of label materials: (coated) papers, PE/PP or cardboard. Due to its flexibility the XLP 50x is ready for numerous applications and will support your identification and traceability processes, mainly related to primary and secondary packaging in the following industries: • Food manufacturing & processing • General distribution and logistics • Consumer goods • General manufacturing • Pharmaceuticals • Electronics • Ticketing Your benefits: • lncreased Productivity • Reduced Downtimes • High Print Quality • Convenient Maintenance • Ultimate Use Friendliness

Request for a quote

PARTEX MARKING SYSTEMS GMBH

Germany

PLT is a serie of labels primarily for thermal transfer printing. Its material is UL approved self adhesive polyester. 1-track or 3-track, 38 mm (standard) or 76 mm core diameter and perforated. The PLT range also includes adhesive, self-laminating and printable wrap-around labels. Its material is UL approved MT310 transparent polyester. Material UL approved polyester with acrylic based permanent adhesive. UL approved MT310 transparent polyester with acrylic based adhesive (wrap-around) Colors yellow, silver, white yellow, white (wrap-around) Print Printable in recommended standard thermal transfer printers with standard label design software. Temperature range Service temperature range: –40°C to +150°C (–40°F to +302°F). Minimum application range: +10°C (+50°F). Storage stability: Two years stored at +21°C (+70°F) and 50% relative humidity (RH). Resistance UL code PGGU2. Excellent resistance to isopropyl alcohol, oil and water.

Request for a quote

ASTRONOVA GMBH

Germany

Valued for its image extreme durability, print speed and ability to print on a wide variety of substrate material, Thermal Transfer technology has been and continues to be a printing industry standard. Thermal transfer printers excel at creating dense print output with crisp edges that hold up well to abrasion; attributes required in most barcoding applications. Being so versatile, there are many types of Thermal transfer ribbon formulations along with multitudes of different substrates that can be printed on. It is very important that you have the correct ribbon and material combination to ensure proper transfer and durability. With 25 years’ experience in manufacturing and testing Thermal transfer ribbon and material, we at GetLabels can guide you through the decision-making process so that you have the proper combination suitable to your application. All of our Thermal ribbon and material are compatible with all thermal transfer printers from the leading manufacturers.

Request for a quote

HERMA GMBH

Germany

Thermal papers are an efficient solution for printing variable price, weight, or batch information. In this section, you can find a wide range of all quality levels.

Request for a quote

SERIN GMBH

Germany

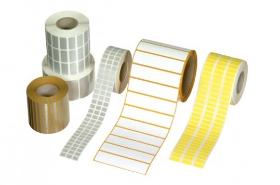

Self adhesive label papers Thermal, metalised, PP, vellium Paper on Paper Paper on Film Film on Film Rolls and Sheet

Request for a quoteResults for

Thermal labels - Import exportNumber of results

11 ProductsCountries

Company type