- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thermal coats

Results for

Thermal coats - Import export

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Extrusion Coating EC Thermal Imaging System from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes.The series also features dedicated hardware and software options, which have been created specifically for specialized extrusion coating, co-extrusion and laminating processes. MP Linescanner With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Areas of application: G-Sealed can be used in many applications, but is particularly suitable for the automotive industry due to its excellent thermal and chemical resistance. Customer benefits: • Non-reactive and non-hardening coating. • Immediate (sealing) immediately after assembly of the connector • A dry, elastic and non-slip coating • Good thermal and chemical resistance • Applicable for metallic and non-metallic materials • Does not require labeling and is therefore not hazardous or harmful to the environment

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

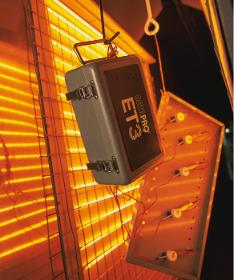

DATAPAQ temperature profiling systems include high-accuracy industrial-strength data loggers, analysis software, thermal barriers, and thermocouples. EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products. With choice 4 or 6 measurement channels, the EasyTrack3 system allows you to monitor and record product temperatures in your curing oven. Use the detailed temperature profile data to: • Monitor and prove QA • Optimize your powder coating oven performance and save energy costs • Identify potential problems in your powder coating process and correct them quickly and efficiently The range of thermal barriers is designed to match different coating applications or operational needs. These provide dual protection confidence using microporous insulation and phase change technology and maintain logger temperatures at a level to guarantee the accuracy of the temperature measurements recorded.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Designed to be accurate, repeatable, and easy to operate IEC584 color standard (green) for type K thermocouples Strong crimped plug/cable attachment CLAMP thermocouples clip to non-ferrous components Clamp Surface for measuring substrate temperature Clamp Air for measuring ambient temperature ADHESIVE PATCH thermocouple Ultrafast response, single strand and PTFE coated Minimal thermal mass – ideal for small items or plastics EXPOSED-JUNCTION thermocouples for use on test pieces that are left permanently rigged Attached to the substrate by spot welding, soldering, use of high-temp tape or screw EXPOSED-JUNCTION THERMOCOUPLE – HIGH-TEMPERATURE featuring a glass-fiber cable Attached to the substrate by high-temp tape or screw, or spot-welded into position Placed at critical points on the product, thermocouples enable temperature profiling with a DATAPAQ Oven Tracker. All DATAPAQ probes conform to the highest standards and provide the most accurate data possible.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WESTMARK GMBH

Germany

• high-quality non-stick coating • good thermal conductivity ensures uniform browning • of course PFOA-free (according to EU regulation 2017/1000) • heat resistant up to 230 ° C

Request for a quoteResults for

Thermal coats - Import exportNumber of results

7 ProductsCountries

Company type