- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- textile coating

Results for

Textile coating - Import export

SCHÖPP-SPORTBODEN GMBH

Germany

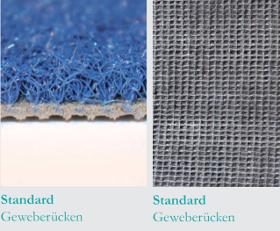

The new generation of fabric backing After the carpet raw material has been tufted and dyed in the colour desired by the customer, the tennis floor is given the necessary nap binding and stability by the back coating. With the classic latex coating, the yarn binding and the coating with a textile secondary backing (action back) are achieved using a highly chalk-filled latex dispersion. This makes the carpet relatively heavy and stiff. With this coating technology, the elasticity only comes from the yarn layer, which is also the wear layer. This means that tennis floors with a classic woven backing become harder year after year, particularly in the main running areas that are subject to the most wear. There is no sustainable elastic layer.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Ci3000+ Weather-Ometer and Fade-Ometer with their advanced digital control systems, represent monumental achievements in applying digital and optical technologies in easy-to-use laboratory weathering instruments. The 3000 Series is approved by many OEMs in the textiles, paints & coatings and plastics industries as the exclusive platform to deliver accurate, reproducible and repeatable results for predicting service life. The 3000 Series has been certified CE, UL, CSA, ISO and EN compliant. Key features of this instrument include: a rotating sample rack to maximize uniformity over all specimens; custom designed nozzles to provide uniform specimen and rack spray; ASTM Black Panel Thermometer or ISO/DIN Black Standard Thermometer to control and monitor temperature at specimen level to ensure test repeatability. 4500 W water-cooled xenon arc lamp Total exposure area of 2,188 cm 2 (339 in 2) TFT full color 12" touch screen control panel display of all test parameters Direct setting and control of Black Panel Temperature; uninsulated (BPT) or insulated (BST) Direct setting and control of relative humidity Direct setting and control of specimen chamber air temperature Display of diagnostic messages 14 factory pre-programmed test methods (Weather-Ometer); 6 factory pre-programmed test methods (Fade-Ometer) Space for 12 custom programs; sub-cycle capability Multi-language capability (English, French, German, Spanish, Japanese, Chinese, Korean, Turkish) Streaming data output via ethernet or USB port. USB thumb drive included SmartDamper TM to reduce test variability in chamber temperature and humidity and compensates for changes in ambient lab conditions SmartLight Monitor TM verifies that correct light capsule is installed Filter combinations available to meet all common test methods Air intake dust filter CS-7 xenon lamp cooling system Chamber viewing window in door Universal electrical configurations to meet local frequency, voltage, and electrical requirements Meets CE, UL, ISO EN and CSA safety requirements Automatic test countdown based on time or radiant exposure VibraSonic TM Humidification System Specimen Holders available to accommodate many sample types Calibrated xenon reference lamp Water purity indicator Dual Black Panel Temperature (BPT) and Black Standard Temperature (BST) Measurement/Control including uninsulated BPT and BST sensors Monitoring of second wavelength: 300-400 nm, 340 nm or 420 nm including beam splitter, dual filter housing and lamp calibration Special locking casters and frame modification WXView (Weather View) Data Acquisition System 2-tier rack - 60 specimen positions

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

Our coating line concepts stand for maximum production output, low energy consumption and highest precision regarding temperature distribution, air circulation and coating application. We can offer many different coating application units, such as combined floating knife/ cylinder coating head, knifeonrubberblanket coating unit, magnet roll coating unit, paste dot or screen coating unit, powder scatter coating assembly, kissroll unit, impregnation bath, reverseroll coating unit and vertical floating knife coater. Our lines are used for coating many kind of end products, such as airbags, automotive interior, truck tarpaulin, architectural fabric, protective clothing, emery cloth, paragliders, awning cloth, billboards and many others.

Request for a quote

BRÜCKNER TEXTILE TECHNOLOGIES GMBH & CO. KG

Germany

We supply any kind of carpet finishing and coating lines from the raw product to the finished article. Depending on the carpet type and the required drying capacity after washing, dyeing or printing, in finishing, coating or laminating BRÜCKNER offer different dryer systems. Our special DUOTHERM dryer is mainly used in textile and carpet coating lines because of many benefits. The dryer has separate air circuits, continuously controllabe via frequency inverters, a separate heating of the upper and lower dryer sections, adjustable temperature difference of up to 60°C, inversed thermo zones, 3 metre each and many more.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Textile coating - Import exportNumber of results

4 ProductsCountries

Company type