- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- test station

Results for

Test station - Import export

QUELLTECH GMBH

Germany

Within the frame of quality assurance, the forged pieces of this client have to be checked in an inline inspection with respect to several parameters: Inner and outer diameters, as well as the absence of surface defects have to be verified. Video of inline forgings inspection for dimensional accuracy and surface defects with QuellTech LaserScaner. Particular Challenges Manual inspection carried out until now turned out to be not reliable enough, particularly after an increase in production. The final rejection rate has seriously affected the productivity of the entire manufacturing process. A solution for a contactless inline inspection was needed. The QuellTech Solution A testing station including an index table has been designed. This configuration acts as a support for two QuellTech Q4-60 laser scanners, used for inspection of the parameters mentioned above.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station to review the gas detection devices. The control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 is possible. All gases can be connected to 1 liter aluminum compressed gas cans. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for checking the gas detection devices according to G465. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-US has a vacuum manometer. In the PS 403-US model, the control buttons are replaced by toggle switches. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Test station for revising gas detection devices. The control of the minimum sensitivity (10ppm) and the control of the display accuracy 1Vol% - 2.2 Vol.% -100 Vol% -5 Vol.% CO2 are possible. All gases can be connected to 1 liter aluminum compressed gas cans. The remaining pressure of the bottle is always displayed. If larger quantities of gas are required, a steel pressure gas bottle can also be connected via an adapter and the pre-pressure reducer. Rather than a pressure gauge, the PS 403-U has a vacuum manometer. With flow measurement. The test gas is conditioned (humidified)

Request for a quote

MERECS ENGINEERING GMBH

Germany

EOL test stand for e-charging columns and their power electronics for the simulation of different electrical loads and mains fluctuations. The test stand has automatic contacting and achieves high test throughputs in end-of-line operation. Different variants of the power electronics of electric charging columns can be tested. On the software side, Merecs Engineering relies on NI-LabVIEW and NI-TestStand.

Request for a quote

HOCHRAINER GMBH

Germany

Test station for foot-activated parking brake

Request for a quote

HOCHRAINER GMBH

Germany

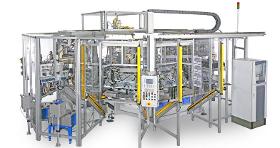

Rotary indexing assembly table for power window mechanism including testing station .

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Axial bearing 1000 N press, locking ring assembly and testing station

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

For everyone who expects more: special gearboxes from the specialist. We provide gear solutions for your individual performance requirements, including designs, tooth developments, prototype manufacture, extensive tests and documentation, right up to the delivery of the series. Our customised gears include: Single-stage bevel gears as control or reverse gears Labyrinth-sealed gears with a degree of efficiency of > 98% High temperature gears for ambient temperatures of up to 300°C Saw drive gears Test station gears with output speeds of up to 12000 min -1 Double gears with two transmission ratios Robotic gears Spur gears High precision gears And much more

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Design Gear – The customised special gearbox For everyone who expects more: special gearboxes from the specialist. We provide gear solutions for your individual performance requirements, including designs, tooth developments, prototype manufacture, extensive tests and documentation, right up to the delivery of the series. Our customised gears include: Single-stage bevel gears as control or reverse gears Labyrinth-sealed gears with a degree of efficiency of > 98% High temperature gears for ambient temperatures of up to 300°C Saw drive gears Test station gears with output speeds of up to 12000 min -1 Double gears with two transmission ratios Robotic gears Spur gears High precision gears And much more

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The RESISTOMAT® model 2329 is particularly suitable for fast measurements of low resistances in automated processes. Up to 50 measurements per second can easily be performed. The device complies with the latest CE guidelines and is designed for laboratory use as well as heavy-duty industrial applications. A 2-fold and 4-fold comparator with switching outputs has been included for classifi cation and selection; this feature is particularly useful for serial tests. One special application involves the measurement of contact resistances (dry-circuit measurement); the load voltage in this case is limited to 20 mV in order to prevent fritting (DIN IEC 512). The RS232 (standard) and IEEE488, USB and Ethernet (option) computer interfaces allow the set-up of fully automatic testing stations. The PLC interface allows easy integration into your production process control.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Workbench mounted Torque Transducer. Crane’s stationary transducers are the quality choice for the testing of all continuous drive, impulse and hand torque tools in the workshop and production line-side environment. For best results with impulse tools we recommend the use of a Crane CheckStar rotary torque transducer with a suitable joint kit rather than a stationary transducer. Stationary transducers are used off the production line in workshop or line-side test stations. Combined with joint kits that represent the production joint condition, the stationary transducers form an effective off line test for verification of assembly tool performance. Key Features: - Static accuracy ± 0.25% FSD (bi-directional) - Plug and Play with Crane display systems (UTA) - Combine with joint kits for workshop simulation of hard to soft joints - Built-in workbench mounting flange - Rugged and durable construction, aluminium housing, stainless steel shaft - Ingress protection rating IP40.

Request for a quote

BERATRONIC GMBH

Germany

Our services •Layout creation •Material procurement •SMD assembly •Manual and semi-automatic •Mounting •Reflow and wave soldering •Selective soldering •Automatic Optical Inspection (AOI) •X-ray inspection •System assemblies •In circuit tests and •Function test •Revision and repair •Rework Station •Short delivery times

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – Large container / handling stations (tubs) are semi-automatic system components for separating, filling, sealing and capping tubs and canisters and can be used individually or in combination. This enables the precise and modular realisation of your specific tasks on the basis of tried and tested stations. Container separating stations Filling positions with filling valve(s) or manual filling stations Sealing stations with head space gassing or evacuation Capping and screwing systems We would be delighted to integrate these or other handling stations in your production process. A common, unified transport system is only one reason for the reliability of each station and the interaction with the upstream and downstream processes. Buffer sections and synchronisation devices are standard here, and can also be combined with our stockpiling systems.

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The VA 40 variable area flowmeters are suitable for measuring liquids and gases The standardized device design is available with various connections that conform to standards. The glass measuring cone, protected by a metal sleeve with a viewing glass, makes it easy to read the flow directly and observe the medium. The suitability for measuring the flow of gases in accordance with the DVGW G260 process sheet has been certified by the DVGW testing station at the Gas-Fired Thermal Institute in Essen.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NANOSYSTEC GMBH

Germany

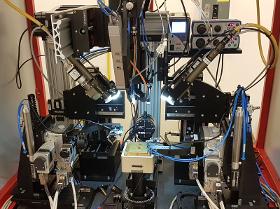

NanoHybrid provides a large degree of versatility. The active alignment, test and assembly station combines various assembly methods including gluing, laser welding or selective laser soldering. In addition, the station offers opto-electronic testing capability. Therefore, NanoHybrid is ideally suited for the development and small serial production in manufacturing companies or in research institutes. In such a product development area, an active alignment station needs to cope with opto-electronic and other precision devices with varying sizes and characteristics.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Quality made by Siempelkamp Based on decades of experience and using state-of-the-art technology, we oer individual, comprehensive testing of your components. Key features Advantages highly-qualied sta numerous certications (see download area) individual pressure and leakage tests non-destructive testing methods (VT, PT, MT, UT and test station for RT) Innovative 3D laser and video scan measurement techniques decades of experience mobile hardness testing greatest accuracy state-of-the-art technology

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

ZwickRoell`s HDT/ Vicat all round instruments have been designed in a manner that enables them to be convenient for testing in research and development, inwards checks of goods, monitoring of production and also in education and training. Versions with up to 6 testing stations can be made available. The instruments include measuring stations which can be lowered in an automatic manner and then there is the optional test-weight lowering. The optional re-cooling device is able to reduce the oil re-cooling time as a result of which high test-rates are a possibility. The advantages included here are that the tests possible to the standards of ISO 306, ASTM D 1525, ISO 75 and ASTM D 648. Key Advantages and Features: - Measuring station lowered automatically - Optionally available automatic test-weight lowering - Optional internal re-cooling device for rapid attainment of starting temperature - Testing to ISO 306, ASTM D1525, ISO 75 and ASTM D648.

Request for a quote

MÜLLER CO-AX GMBH

Germany

Coaxial highpressure valves are valves with two connections and two switching positions. The pressure range extends from vacuum up to 400 bar. The wall thicknesses for the valve housing and head tube as well as the selection of the seals and the retaining screws are specially designed for high pressure applications. This series is typically used in gas filling stations and test benches, in compressor and hydraulic systems and in washing machines. The KB valve types have a special feature They do not require dynamic plastic seals and can be used in cryogenic application.

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Gas-Pro of the company Crowcon is developed for protection in tight, dangerous areas. Gas-Pro offers display up to 5 gases in a compact, robust solution, which Resist tough areas and everyday use! Features of Gas-Pro Measurement up to 5 gases at the same time Clear dispay on top of the device, with two-coloured back lightening Internal pump (optional) Automatic, fail-safe detection of suction adapter Special mode for use before access Three-coloured safety- display Obvious alarm display: vibration alarm, signal tone >95dB and clearly visible red/blue LEDs Integrated, shock-proof casing with protection class IP65 & IP 67 against penetration of water and dust Suitable for use with newest gas test stations, for portable use, wall- or table assembly. Following gases can be measured (max. 5/device): Combustible gases (Ch4; 0-100%LEL) Chlorine (0-5 ppm) Carbon dioxide (0-5 vol.%) Carbon monoxide (0-500 ppm) Ozone (0-1 ppm) Oxygen (5-25 vol.%) Sulphur dioxide (0-10 ppm) Hydrogen...

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

With the simple, robust and maintenance-free single gas monitor GasAlertClip Extreme of BW-Technologies a reliable monitoring and detection is secured (e.g. personal security) of all threats by single gases, whereby the measured value is displayed in real-time. The operating time is limited to 2 years and absolutely maintenance-free, batteries neither need to be charged nor to be exchanged. Thanks to simple operation time exposure reduces considerably, therefore this device is excellently suitable for industrial applications. Features of GasAlertClip Extreme: Large LCD-display indicates remaining operation lifetime in months, days, and hours Impact- and water-resistant Self-test of all functions of sensor, battery, electronic and acoustic/ optical alarm Compatible with the automatic testing station “BW-MicroDock II” Bright, wide-angles blinking alarm display With integrated vibration alarm for surroundings with higher noise level Daily self-test activated by user Recording and...

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

BORRIES built-in impact units are suitable amongst others for marking applications on transfer lines, rotary tables or testing stations. Because of the big usable stroke workpieces with different heights can be marked without any adjusting.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

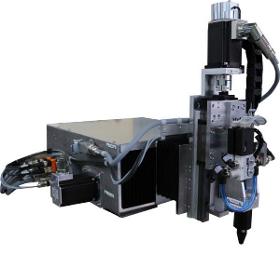

The marking unit 315 is a very well protected and highly robust device designed for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. The set of a marking head and a controller is integrated as a built-in unit by system producers for direct workpiece marking e.g. in transfer lines, production machines or gauging and testing stations. The pneumatic (PN) or stepping motor (SM) adjustment unit allows to forward the marking unit to the workpiece even at places which are difficult to access. Marking unit for marking processes: scribe, stylus, dot marking and DataMatrix coding (ECC200)

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

The built-in unit 322 is a highly robust device for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. Together with a marking head and a controller this marker is integrated as a built-in unit in our special systems or by system producers for direct workpiece marking, e.g. in transfer lines, production machines or gauging and testing stations. The marking head is directly mounted underneath the coordinate unit. Marking areas 100 x 100 mm, 100 x 50 mm, 40 x 50 mm, 150 x 100 mm, 150 x 150 mm, 250 x 150 mm (X/Y) – other sizes possible.

Request for a quoteResults for

Test station - Import exportNumber of results

27 ProductsCountries

Category

- Testing equipment (7)

- Embossing machine tools (2)

- Import-export - electrical and electronic equipment (2)

- Laser - cutting and welding machines (2)

- Chemicals - Basic Products & Derivatives (1)

- Measurement and control instruments (1)

- Measurement and regulation equipment and instruments - electricity and other energy (1)

- Mechanical engineering - custom work (1)

- Printed circuits (1)

- Stamping - machine tools (1)

- Valves for industrial fittings (1)