- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- temperature monitoring systems

Results for

Temperature monitoring systems - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® Explosionproof screw plug or flanged immersion heaters ( Ex ) are perfectly suited for direct heating of liquids or gas / air mixtures in hazardous areas. The devices are available with attached or integrated temperature monitoring systems. For these heaters various high quality stainless steel grades are available. The electical immersion heater type 94./..EEs….T.(.) is designed for the heating of liquids and quit gasair mixtures in the zone 1 and zone 2. The standars elements, mentioned in this list are suitable for DGRL (code 97/23/EG) Art. 3 Para. 3. The elements can be suited (on request) to other uses requiring another classification according to DGRL.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

CSN ® Explosion proof cartridge heaters as direct heaters for liquids or gases in hazardous environment. These units are equipped with a heating bundle or a replaceable ceramic heating element. For temperature control these heaters are available with an integrated temperature monitoring system. These devices are available in various material grades. The electric cartridge heating element type 93./..EEx….T.(.) is designed for the heating of liquids in the zone 1 and zone 2. The standars elements, mentioned in this list are suitable for DGRL (code 2014/68/EU) Art. 4, Para. 3. The elements can be suited (on request) to other uses requiring another classification according to DGRL Further information about our CSN® ExCartridge Heater

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

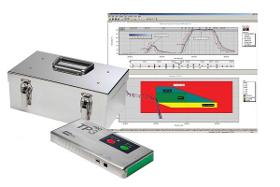

Process engineers worldwide use Datapaq temperature profiling and monitoring systems to optimize product quality, reduce waste, confirm compliance with industry standards and more. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution – complete with data logger, custom thermal barriers and our Insight™ Software. These bespoke systems enable through-process temperature profiles to be obtained in processes where trailing long thermocouples are not an option. Each thermal barrier is designed in close collaboration with the end-user, providing the optimum solution for every application. Data Loggers Fluke Process Instruments has a wide selection of data loggers ranging from the stainless steel cased Datapaq TP6 and the rugged Datapaq DP5 for high temperature heat treating to the Multipaq 21, Datapaq XL2

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq AutoPaq is a customized thermal profiling system for temperature monitoring of paint, adhesive and sealant cure processes used in the automotive assembly market. Offering up to 20 channels of measurement in a single system, the AutoPaq is the perfect tool for performing detailed cure validation of new installations or optimizing existing lines for new models. With real time RF capability, the system may also be the preferred choice for routine live monitoring of paint operations as part of standard QA procedures. For detailed information and specifications, download the AutoPaq brochure. To learn how the AutoPaq can benefit your operation, download the 3 Key Wins document. Datapaq CoilPaq Thermal Profiling System The Datapaq CoilPaq is used in surface coating lines to monitor the temperature profile of the coil strip at various points across its width, as it is fed through the oven. The design of the CoilPaq allows you to place this instrument

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Customers worldwide use Datapaq® temperature profiling and monitoring systems with their powder coating equipment in automotive and industrial powder coating to optimize product quality, reduce waste and prove compliance with ISO9000. When standard and specialty systems will not meet your exact application requirements, Datapaq will build a custom system using Insight™ thermal profiling software, an extensive range of custom barriers and thermocouples, as well as the Datapaq DP5 and Datapaq TP3 data loggers. In addition, Datapaq offers a complete thermal profiling system for real-time data analysis -TM21 Radio Telemetry System. Oven Tracker Insight Software Datapaq powerful Insight analysis software has been designed specifically to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process. Complex calculations are simplified, allowing quick and comprehensive analysis.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNOTRANS SOLUTIONS GMBH

Germany

MULTI-ZONE TEMPERATURE CONTROL- AND MONITORING SYSTEM WITH NON-CONTACT FLOW MEASUREMENT. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. By using the frequency inverter, the already high basic efficiency is optimized and the pump characteristic curve will be optimally adapted to the respective operating conditions. The flow measurement of the individual temperature zones is carried out using noncontact measurement technology according to the ultrasonic principle.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ temperature profiling systems include high-accuracy industrial-strength data loggers, analysis software, thermal barriers, and thermocouples. DATAPAQ AutoPaq is a customized thermal profiling system for temperature monitoring of paint, adhesive and sealant cure processes used in the automotive assembly market. Offering up to 20 channels of measurement in a single system, Datapaq AutoPaq is the perfect tool for performing detailed cure validation of new installations or optimizing existing lines for new models. With real time RF capability, the system may also be the preferred choice for routine live monitoring of paint operations as part of standard QA procedures. Range of silicone-free barriers providing safe and contamination-free options to suit single and multi-run operations Oven Insight Professional software written for the automotive paint engineer to perform process QA or full validation quickly, efficiently and accurately

Request for a quote

LOGOSYS LOGISTIK GMBH

Germany

GMP-compliant storage and picking 91,000 euro pallet spaces and approx. 45,000 sqm of system space are available for you at the Darmstadt location and in external warehouses for storing and picking your products. The equipment in our warehouses meets all the requirements for GMP-compliant storage. High-quality technical equipment, validated IT systems and trained personnel ensure proper storage and an optimal material flow. PALLET PICKING & SHIPPING PREPARATION Previous Next 12345 Well-tempered storage Our warehouse equipment is particularly geared towards the high requirements of the pharmaceutical industry. Active night cooling and powerful air conditioning systems ensure a storage temperature of +15 to +25 degrees Celsius in all storage areas. Compliance with the required temperatures is checked and documented around the clock by a computerized, validated temperature monitoring system. High security, The safe storage of your products is particularly important to us.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The DIGIFORCE® 9307 monitors processes in which precisely defined functional relationships between two or more measured quantities need to be demonstrated. These measured quantities are recorded synchronously during the manufacturing process or subsequent functional testing to produce a measurement curve, which is then assessed using graphical and mathematical evaluation techniques. After internal evaluation, the measurement curve and computed evaluation results are visualized on the color display and are also output at the external control interfaces. The processes in the controller are optimized by a powerful real-time operating system to achieve an extremely fast evaluation cycle: it typically takes just 15 ms to deliver the global OK or NOK evaluation result, which can then be analyzed by the higher-level controller.

Request for a quoteResults for

Temperature monitoring systems - Import exportNumber of results

10 ProductsCountries

Company type