- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tank heating systems

Results for

Tank heating systems - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® tank heating units are particularly suitable for the direct heating of liquids (Oil, Water, Emulsions), air and gases. They contribute to the avoidance of paraffin clouds in fuel oil or Diesel storage tanks. In relation to the process, we provide you with tank heating units with tubular heating elements made of stainless steel which we adjust to the respective application situation and the medium to be heated in consultation with you. We offer our series “THF” a suspended, on a chain flexible solution to keep heating oil or diesel fuel in the extraction line pumpable. As a fixed version, we recommend our industrial immersion heaters for heating liquids. Further information about our CSN® Tankheizkörper

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Coating of pipings and air ducts, firing, boiler and heating systems, tanks, exhaust systems, silencers, light-metal bodies on utility vehicles Repairs to mechanically (stone impact) or chemically (de-icing salt) damaged aluminium rims Shielding of non-metallic materials, e.g. cardboard, wood, glass or plastics etc. Advantages and benefits Excellently suited for sole, decorative corrosion protection Universal protective and decorative coating for all materials Economical due to low consumption and self-cleaning spray valve High covering capacity Fast-drying

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple product viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION HMI and SCADA with touch screen system Mixer tank with raw material vacuum sucking technology Can handle multiple viscosity from high to low Double jacket mixer tank for heating and cooling system with pressure and vacuum technology Product certification transferring pump Flowmeter system Exchangeable blades; multiple blades types and design has been manufactured to conform the product types and textures Piping gel cooker machine; Time and speed can be adjusted up to the product needs Automatic product transfer system can be managed with the PLC screen Buffer tank transferring system; cooked products will be transferred from cooker by a homogenizer sucking system Homogenizer with a compact design; with exchangeable heads (conforming the product type).

Request for a quote

ERC ADDITIV GMBH

Germany

grotamar ® 82 kills micro-organisms in diesel and heating oil quickly and reliably and thereby protects against malfunctions and damage in engines and heaters. THE EFFECT Water in the diesel, condensate water, and heat in the tank system provide conditions for the growth of bacteria, fungi, and yeast. They form bio-sludge and organic acids which lead to filter clogging and corrosion. A failure of the engine or heating system is the result. By adding grotamar ® 82, the growth of micro-organisms can be prevented. THE RESULT grotamar ® 82 quickly kills microbial pests and effectively protects against corrosion. Expensive repairs are avoided. grotamar ® 82 was also successfully tested as an initial biocide by Öl-Wärme-Institut in an oil burner pump endurance test and fulfils the criteria catalogue for heating oil (extra light) additives.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

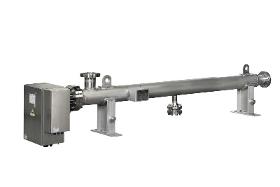

CSN® explosionproof flow heaters are used for heating up flowing gases and liquids in hazardous areas. The devices consist of explosionproof flanged immersion heaters, which are installed in corresponding pipe or pressure vessel. Our products realize individual solutions for complicated technical process. Different heating systems for heating up liquids, nitrogen or other gases activate exact determinded processes in chemical factories. In close discussion with our customers problems will be defined and changed in technical optimale solutions. Our QualityManagementSystem ensures the high quality level of our customers. Further information about our CSN® Exflow heater

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

Our quality SANHA ball valves are made of brass CW 617N and can be delivered in a multitude of versions such as with threaded and press ends, or in the dimensions 15-54 mm, 16-26 mm and ½" to 2". The ball valves can be easily and quickly combined with all SANHA systems, thus providing a real alternative to conventional products. With SANHA ball-stop valves we provide our customers with the oppurtunity for an optimal safe and at the same time very economical solution for the installation of machinary, equipment or other facilities such as risers.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Like the slightly less powerful MA series, it is guaranteed absolutely exhaust-free hot air. In addition, the units can be operated not only with oil, but are also approved for gas operation. The operating mode can be flexibly adapted to the conditions on site. Thus, the devices can be used in all areas. Hot air hose systems can also be connected without any problems thanks to the high-performance radial fans. Consequently, effective heating from outside is also possible without any problems. The recirculation module ensures efficient and economical operation. The oil burner blowers are made of high-quality materials by renowned manufacturers. They work so efficiently that 93% of the energy can be converted into heat.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quoteResults for

Tank heating systems - Import exportNumber of results

9 ProductsCountries

Company type