- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface treatment of metals

Results for

Surface treatment of metals - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

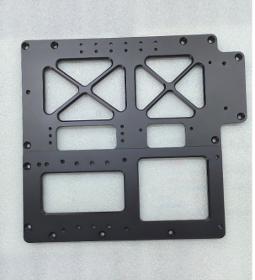

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

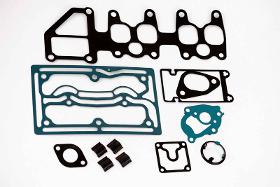

Our rubber-coated metal strips are used in numerous applications, such as engine and aggregate seals. In addition to NBR, we also coat metal strip with EPDM, NR, HNBR and FPM in thicknesses of 10 μm - 2 mm. The metal strips can also be coated with an anti-friction coating, which offers extremely high resistance to heat and special sliding ability. The resulting further processing quality enables them to be used wherever parts made of metal strip with sealing, sound-absorbing or vibration-damping properties are required. The very good bonding between elastomer and metal, combined with outstanding deep-drawing properties, shows the superiority of this coating. The metal strips can also be top-coated with decorative lacquers on both the metal and the rubber coated side (e.g. as a distinguishing feature in the company's own production for top and bottom sides).

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

In coil coating, an organic coating is applied to the surface of a metal strip in a continuous process. The HUEHOCO portfolio includes both decorative and weather-resistant coatings as well as system solutions for a firm bonding of the metal strip with various rubber compounds and/or various plastics. For technical applications, there are also high-temperature resistant and non-stick as well as anti-friction systems, directly rubber- or plastic-coated metal strips. Since 1989 we have been the first company in the world to offer our customers the opportunity to have their goods delivered "endlessly" wound with more than 200,000 metres in a single strip on metal or plastic spools. Depending on our customers' requirements, we can process all wrought aluminium alloys, stainless steels, steel grades and non-ferrous metals available on the market in various degrees of hardness.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Functional and decorative coating systems In addition to coatings for Coil Coating applications and related areas, SI-Coatings GmbH develops and produces individual paints and varnishes for any application. These are technical, functional and decorative coatings.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

An innovation for decorative applications is the stripe coating on our narrow Coil Coating line at First American. This is a complete coil coating process in which we are able to leave tightly toleranced, unpainted stripes on the carrier strip. These give the decorative effect to the finished article, while the coated areas are coated with an adhesive system (e.g. automotive trim material or white coating with a defined black stripe, etc.). As always, all metal strips available on the market can be used as metal carriers; all coatings can also be used. This leads to a smart product, allowing you a multitude of new, innovative applications.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

This coating system is mainly used for the coating of cold rolled strip, but can also be applied to other metals. It is applied in the last processing step and enables a special gliding ability and heat resistance on coated surfaces.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Rubber-to-metal bonding Our adhesive build-up provides strong bonding between our metal carrier and your rubber. With our know-how, we are able to bond a wide variety of compounds such as NBR, CR, EPDM, SBR etc. for you. Plastic-to-metal bonding Whether PC (polycarbonate), PVC (polyvinyl chloride), ABS (acrylonitrile-butadiene-styrene), CAB (cellulose acetobutryate), PP (polypropylene), TPU (thermoplastic polyurethane), PA (polyamide) and polyolefinic plastics or other thermoplastics as well as duroplastics - we ensure that you achieve optimum adhesion between the plastic and our metal carrier.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

We are able to produce various shades of high-quality decorative polyester top coats in small and very small batches using a paste system – resulting in a very competitive pricing for our customers.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quote

LEICA MICROSYSTEMS

Germany

The EM ACE600 sputter coater is a versatile high vacuum film deposition instrument for your FE-SEM and TEM applications. Whether you need to •enhance contrast by a fine-grained metal layer, •produce nanometer thin but robust carbon films, •rotary shadow your sample to make smallest features visible, or to •move into cryo-coating, the ACE600 coater will offer the optimal solution to see more, and this every time.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Oil-water-separation / degreasing bath treatment Treatment of oil-water-emulsions for surface treatment (e.g. pre-treatment of metal parts for ed-paint), recovery companies (e.g. for the treatment of alkaline emulsions for part washing), and so on. Separation of emulgated oil particles and recycling of the cleaned liquid into the degreasing bath Concentration of oil-water-emulsions for disposal Cleaning of the oil-water-mixture for indirect lead-in Principle of this process: Aqueous degreasing baths content a tenside combination, alkalines like soda, caustic soda, phosphate, silicate and further complex molecules. The degreasing bath is loosing its efficiency, when to oil content reaches some g / litre. External pollutions also degrease the degreasing efficiency. By ultrafiltration, the oil content can be separated from the degreasing bath and the oil will be collected in the concentrate. The degreasing bath will be dumped into a buffer tank and then pumped in the working tank of the

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Mass coating of small parts using the hot drum process Coating with the Rotamat is the economical solution for the surface finishing of mass-produced small parts made of elastomers, metal or wood - for example, O-rings, handles, springs or screws. Even geometrically complicated or particularly sensitive parts leave the machine perfectly coated and dry. The coating process is fully automatic, so that the time-consuming insertion or suspension of the parts on racks - which is necessary with conventional automatic coating machines - is no longer necessary. The Rotamat is suitable for a wide variety of coating agents. Typical applications are: — Decorative coating — Bonded coating — Adhesive coating — Anti-corrosion coating — Insulation coating

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

In addition to laser cutting, edging and welding, we at W & K Metallverarbeitung also offer various services in the field of post-processing and surface treatment either internally or through reliable external partners. We execute all requirements according to your required factory standard. Would you like a final assembly of your products? This is also possible with us. For coating and surface treatment, we work together with high-performance partners. • Powder coating (maximum component size 1.6 x 3.0 x 8.0m (W / H / L)) Galvanized galvanizing (blue, yellow or black chromating, max. Length of the component 3,000 mm) • Hot dip galvanizing (spin-galvanizing, high-temperature galvanizing, maximum component length 9,000 mm) • KTL coating • rays Which surface do you want? We are happy to help!

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

These one-way respirator masks are designed and appropriate for work in dusty environment. This mask consists of several layers filter material, with adjustable aluminium nose bracket, foam rubber pad over the nose, and exhalation valve. It fits perfectly through additional sealing lip, as well as easy adjustable woven elastic bands. Weight only 30g. The dust masks are divided into following classes: FFP1 provides protection against dust and other particles with low health risk For example: fish meal, grain dust, mortar, titanium dioxide, talcum, aluminium FFP2 provides protection against dust and other particles with low health risk For example: ash, concrete, wood dust, oil mist, chalk, quartz, cellulose FFP3 provides protection against harmful, toxic, solid and liquid particles. For example: asbestos, surface treatment, metal foundries, construction works Masks of class FFP1 and FFP2 are availably with and or exhalation valve, for masks of class FFP3 exhalation valve is...

Request for a quote

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too Electroplated surface finishing The maximum goods window for galvanising, chromeplating and nickelplating is L / W / D 2800x450x1000 mm. Chrome and nickel plating Galvanising (galvanising without passivation; blue galvanising with variable layer thickness and blue passivation; thicklayer passivation with nanosealing) Electrostatic powder coating Maximum load per hook 30 kg workpieces up to 60 kg Maximum workpiece size L / W / H = 3000/800 /1700 mm More information available at https//www.geck.de

Request for a quote

FÖHRENBACH GMBH

Germany

The machine structure with solid base plate is extremely compact and stable. All necessary components are integrated in the machine housing: mechanical axes, pneumatic components, control with drive electronics and mounted 12 "touch display. Depending on the desired version, the F-Décor 305 can produce surface patterns like circular grainings, côtes de Genève, engravings or decorative millings on mechanical watch parts. The machine guarantees high precision and high productivity. The F-Decor 305 is delivered ready for connection with either 1 or 2 working spindles.

Request for a quote

KAMAT GMBH & CO. KG

Germany

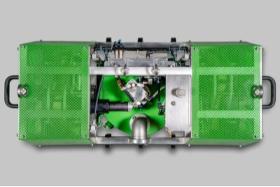

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam DUO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the APC500. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 is only suitable for non-conductive materials. PlasmaAPC 500 is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500: Plastics, rubber, ceramics, glass.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tretra 320R low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 320 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

A cost-effective process for activating plastic and elastomer surfaces is treatment with the PlasmaAPC 500 DUO. Using air as the process gas, large surfaces can be activated under atmospheric pressure. An arc is ignited between two electrodes in an inhomogeneous field. The voltage is about 10,000 V. In the discharge zone, the air flowing through is ionised. The plasma is blown out of the electrode area by the air flow. The substrate can now be treated in the emerging corona. A strip several centimetres wide is treated in the corona. With several parallel plasma generators it is possible to treat surfaces. Due to dangerous voltage potential, PlasmaAPC 500 DUO is only suitable for non-conductive materials. PlasmaAPC 500 DUO is suitable as a pre-treatment unit for the following processes: Bonding, printing, painting. The following surfaces can be treated with PlasmaAPC 500 DUO: Plastics, rubber, ceramics, glass.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the atmospheric pressure plasma system PlasmaBeam RT, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 120 mm, substrates can be treated locally with precision. With our new product, the PlasmaBeam RT, there is now the perfect solution for fast, efficient and wide in-line plasma treatment of 2D surfaces. The RT can be perfectly integrated into existing production lines and thus enables the automated cleaning and activation of various components and web-shaped materials. We create the possibility of up to 120 mm wide plasma treatment, with the usual consistent quality and effectiveness of atmospheric pressure plasma systems from Diener electronic.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Tetra 30 low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 34 up to 50 litres of this plasma system offers enough space to serve series production / automation. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Nano low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 18 up to 24 litres of this plasma system offers enough space to serve laboratory and also series production. Plasma treatment in low-pressure plasma is a proven technique for controlled ultra-fine cleaning, improvement of adhesion (activation and etching) and coating of thin layers on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues. Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Pico low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 5 up to 8 litres of this plasma system offers enough space to serve laboratory and also series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ... Etching of PTFE, photoresist, oxide layers, ... Super-hydrophobic and -hydrophilic coatings

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the atmospheric pressure plasma system PlasmaBeam Mini, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 3 - 5 mm, substrates can be treated locally with precision. In contrast to the Plasmabeam devices, the PlasmaBeam Mini is designed for laboratory use. The PlasmaBeam technology enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Zepto low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of approx. 1 - 4 litres of this plasma system offers enough space to serve laboratory and small series production. Low pressure plasma treatment is a proven technique for controlled ultra-fine cleaning, adhesion enhancement (activation and etching) and coating of thin films on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised. Fields of application: VOC-free cleaning of organic residues Activation before painting, gluing, potting, ...

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam DUO atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quote

DIENER ELECTRONIC GMBH & CO. KG

Germany

Plasma systems from Diener electronic have long since established themselves in a wide variety of industrial sectors. With the PlasmaBeam atmospheric pressure plasma system, you can rely on modern and future-proof plasma jet technology under atmospheric pressure. Due to the treatment width of 8 - 10 mm, substrates can be precisely treated locally. PlasmaBeam technology can be used for inline processes. With the help of robots, 2 or 3-dimensional surfaces can be treated. PlasmaBeam enables local surface cleaning without masking the rest of the surface. For example, cleaning before wire bonding and various processes in the electronics industry. Furthermore, the PlasmaBeam is suitable as a pre-treatment device for the following processes: Gluing, bonding, printing, laminating, soldering, welding, flocking. The following surfaces can be treated with PlasmaBeam: Plastics, rubber, metal, glass, ceramics, hybrid materials.

Request for a quoteResults for

Surface treatment of metals - Import exportNumber of results

39 ProductsCountries

Company type