- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coats

Results for

Coats - Import export

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 2023 anilox roller with 120 lines / cm suitable for Heidelberg XL 106 anilox roller with 100 lines / cm - screening 250 L / inch cell volume 10 ccm hexagonal angle 60° Delivery time: immediately Ref: HE240127A Please ask for price. We ship and install worldwide!

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

We have developed into a leading provider, specialised in various processes for surface coating of transparent plastics. Main focus lies on our abrasion resistant coatings, manufactured under cleanroom conditions. Thermosetting coating systems Using the flooding method a thin layer is being applied or rather “flooded“ on the plate. As a result a flushing effect removing existing dust particles occurs. We can coat plate ware as well as ready deformed parts. Considering provision of material we gladly give you any advice needed. We are familiar in using currently known scratch resistant paint systems, like PHC587, AS4000, AS4700 but also recent paints e.g. XH100, MP100. The plastics used are mainly PMMA or PC. Through these coatings the most transparent plates obtain a higher abrasion resistance, an additional uv protection as well as a higher durability against chemicals or an anti-fog-characteristic. Not only in the sectors of mechanical engineering and automotive, but also in medical

Request for a quote

GERBU BIOTECHNIK GMBH

Germany

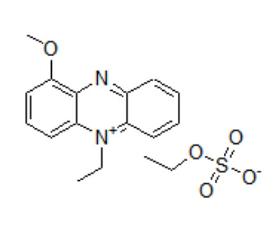

Product group: Reagents CAS-Nr.: [133395-54-7] Shipping condition: ambient MW: 364.42g/mol Formula: C17H20N2O5S

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK Powder Coating enables us to create high-performance and visually appealing product surfaces with long-term corrosion protection and customized color options. Electrostatic powder coating is based on the principle of attracting parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are essential, powder coating is indispensable. These properties have led industries such as appliance manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures, and furniture manufacturing to transition significantly from wet paint to powder coating. The powder coating process is suitable for all electrically conductive and thermally stable solids. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production.

Request for a quote

SCHOCK GROUP

Germany

With SCHOCK Powder Coating, we achieve high-performance and visually appealing product surfaces with long-term corrosion protection and individual color customization. SCHOCK Powder Coating operates with state-of-the-art technology, fast color change cycles, and sustainable, energy-efficient production. Our coating facility is located at the central logistics hub of the SCHOCK Group in DE-72296 Schopfloch. This ensures our customers receive punctual, reliable, and cost-effective deliveries. Electrostatic powder coating relies on the attraction between parts with opposite electrical charges. When high requirements for impact resistance and weather resistance are needed, powder coating is indispensable. These properties have led industries such as equipment manufacturing, machinery manufacturing, medical technology, heating and ventilation technology, household appliances, store fixtures and furniture manufacturing, as well as the automotive industry to largely transition from wet paint

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Coats - Import exportNumber of results

6 ProductsCompany type